Plant fermentation broth and preparation method, beverage and application thereof

A plant fermentation liquid and extraction liquid technology, applied in the field of food processing, can solve the problem of low exopolysaccharide content, achieve high exopolysaccharide content, simple preparation method, and improve the effect of fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

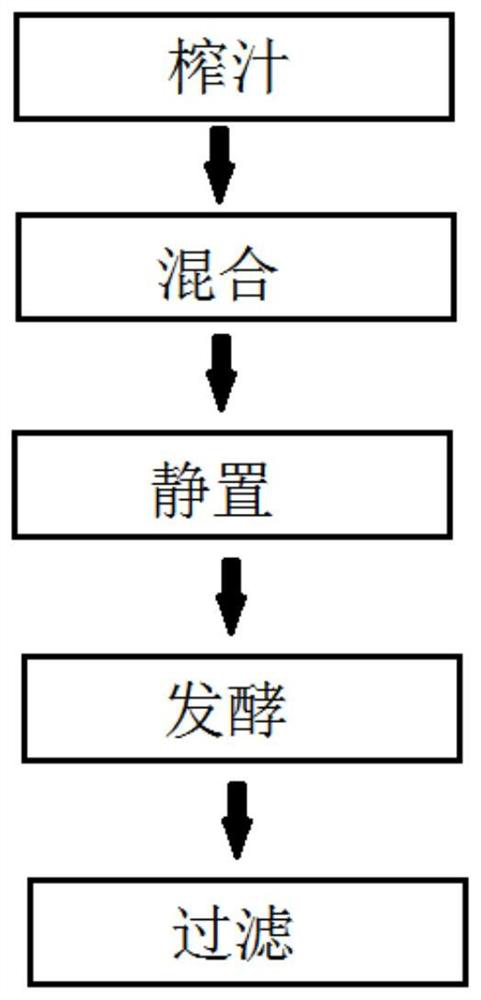

[0036] A kind of beverage, concrete preparation method is as follows (referring to figure 1 shown):

[0037]1) Weigh Hericium erinaceus and dry it for microwave disinfection treatment, then crush it to 100 mesh, put it in a container, feed liquid nitrogen under sealed conditions until the pressure reaches 4MPa, and place it together with the container in an ultrasonic cell pulverizer for ultrasonication Treatment (ultrasonic frequency is 10kHz, ultrasonic power is 8W), then dry to water content to 16wt% and add brown sugar water (concentration is 62wt%) in the ratio of (calculated by weight) 1:1.5 according to material-liquid ratio and carry out beating, Then according to the inoculum amount of 3wt%, add yeast and carry out dark fermentation at 22°C for 60 hours to obtain Hericium erinaceus extract;

[0038] 2) Weigh the Poria cocos and dry it, carry out microwave disinfection treatment, then pulverize and place it in a container (can be a pressure cooker), add 10 times the w...

Embodiment 2

[0044] A kind of beverage, concrete preparation method is as follows (referring to figure 1 shown):

[0045] 1) Weigh Hericium erinaceus and dry it for microwave disinfection treatment, then crush it to 800 mesh, put it in a container, pass liquid nitrogen under sealed conditions until the pressure reaches 16MPa, and place it together with the container in an ultrasonic cell pulverizer for ultrasonication Processing (ultrasonic frequency is 20kHz, and ultrasonic power is 30W), is then dried to water content and is 12wt% and is (according to weight) 1:8 ratio to add brown sugar water (concentration is 70wt%) beating, Then according to the inoculum amount of 7wt%, add yeast and carry out dark fermentation at 28°C for 30 hours to obtain Hericium erinaceus extract;

[0046] 2) Weigh the Poria cocos and dry it, carry out microwave disinfection treatment, then pulverize and place it in a container (can be a pressure cooker), add 20 times the weight of water and cook for 60 minutes,...

Embodiment 3

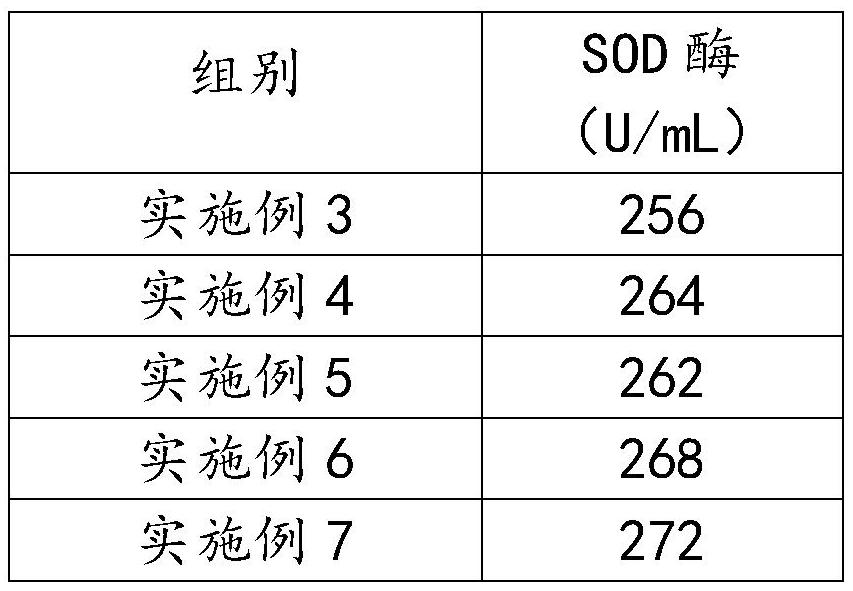

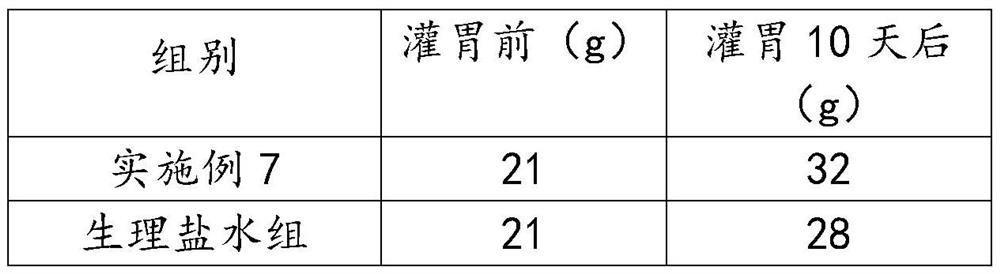

[0052] A plant fermentation liquid, including the following raw materials: perilla 11 kg, apple 52 kg, Hericium erinaceus extract 11 kg, hawthorn 11 kg, jujube 13 kg, malt 5 kg, yam 2 kg, watermelon juice 12 kg, poria cocos 9 kg of extract, 0.02 kg of sweetener (the sweetener is selected from lactose) and an appropriate amount of water. Wherein, the preparation method of the Hericium erinaceus extract is to weigh the Hericium erinaceus and dry it, carry out microwave disinfection treatment, then crush it to 200 mesh, put it in a container, and pass liquid nitrogen under sealed conditions until the pressure reaches 5MPa, together with The container is placed together in an ultrasonic cell pulverizer for ultrasonic treatment (ultrasonic frequency is 12kHz, ultrasonic power is 10W), and then dried to a moisture content of 17wt% and added according to the ratio of material to liquid (by weight) 1:2 Brown sugar water (concentration is 70wt%) was beaten, and yeast was added accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vitality | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com