Antiskid insulating leather shoes

A leather shoes and anti-skid technology, applied in the field of clothing manufacturing, can solve problems such as affecting the use experience, and achieve the effects of improving insulation performance and anti-skid performance, improving anti-skid performance and improving friction coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

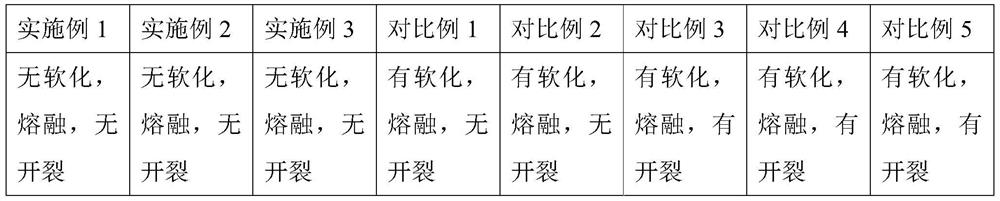

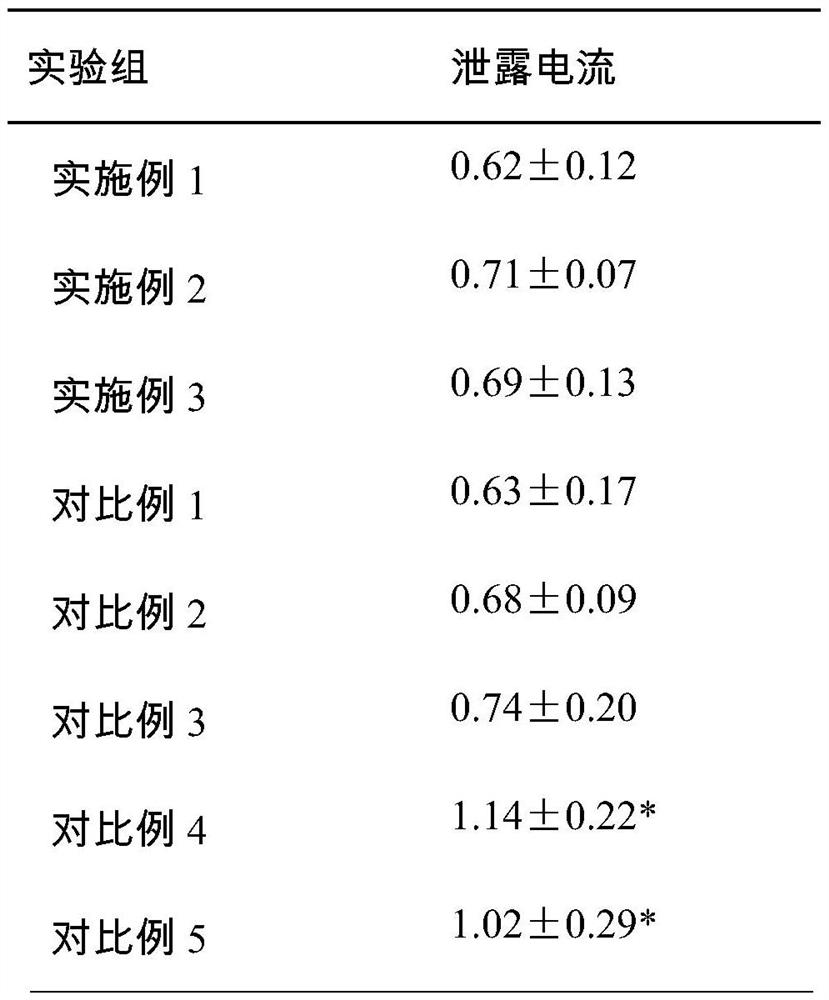

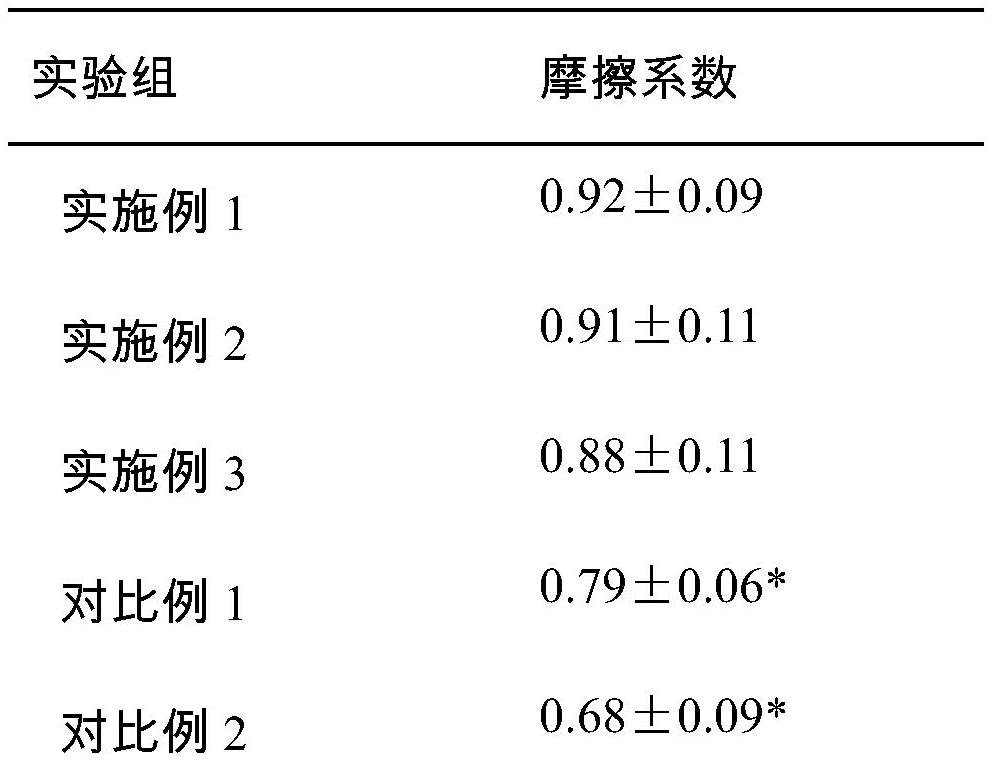

Examples

Embodiment 1

[0020] A non-slip insulating leather shoe, comprising a sole material and a vamp material, the vamp material is cowhide; the sole material is made of the following components in parts by weight: 50 parts of modified styrene-butadiene rubber, ethylene-tetrafluoroethylene 40 parts of copolymers, 15 parts of hollow glass microspheres, 6 parts of vulcanizing agent DCBP, 6 parts of diphenylmethane diisocyanate, 12 parts of blowing agent; The preparation method of the modified styrene-butadiene rubber is as follows: in the polymerization kettle, Add the cyclohexane-hexane mixed glue solution of 3L solution polystyrene butadiene rubber, 23g dibenzoyl peroxide and 90g sebacic anhydride, pass into N 2 Gas, stirred at 180 rpm for 15 minutes, and reacted at 65°C for 3 hours; after the reaction was completed, the product was precipitated with absolute ethanol, then dried in a vacuum oven for 6 hours, and finally the product was extracted with absolute ethanol for 12 hours. Put it in a dry...

Embodiment 2

[0026] A non-slip insulating leather shoe, comprising a sole material and a vamp material, the vamp material is sheepskin; the sole material is made of the following components in parts by weight: 42 parts of modified styrene-butadiene rubber, ethylene-tetrafluoroethylene 32 parts of copolymers, 12 parts of barium stearate, 4 parts of sulfur, 3 parts of formaldehyde condensates of sulfonated acetone, and 8 parts of foaming agent; the preparation method of the modified styrene-butadiene rubber is as follows: in the polymerization kettle, add The cyclohexane-hexane mixed glue solution of 3L solution polystyrene butadiene rubber, 23g dibenzoyl peroxide and 90g sebacic anhydride, pass into N 2 Gas, stirring at 150 rpm for 20 minutes, and reacting at 65°C for 4 hours; after the reaction was completed, the product was precipitated with absolute ethanol, then dried in a vacuum oven for 5 hours, and finally the product was extracted with absolute ethanol for 11 hours. Put it in a dryi...

Embodiment 3

[0032] A kind of non-slip insulating leather shoes, comprising a sole material and a vamp material, the vamp material is crocodile leather; the sole material is made of the following components in parts by weight: 60 parts of modified styrene-butadiene rubber, ethylene-tetrafluoroethylene 50 parts of ethylene copolymers, 20 parts of calcium carbonate, 9 parts of vulcanizing agent VA-7, 8 parts of nonylphenol polyoxyethylene ethers, 15 parts of blowing agents; The preparation method of described modified styrene-butadiene rubber is as follows: In, add the cyclohexane-hexane mixed glue solution of 3L solution-polymerized styrene-butadiene rubber, 23g dibenzoyl peroxide and 90g sebacic anhydride, pass into N 2 Gas, stirred at 200 rpm for 20 minutes, and reacted at 65°C for 2 hours; after the reaction was completed, the product was precipitated with absolute ethanol, then dried in a vacuum oven for 4 hours, and finally the product was extracted with absolute ethanol for 16 hours. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com