Preparation method of porous BiOCl/g-C3N4 heterogeneous nano powder

A nano-powder, g-c3n4 technology, applied in catalyst activation/preparation, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of less heterogeneous nano-powder and achieve narrow particle size distribution, The effect of uniform product distribution and easy control of product composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

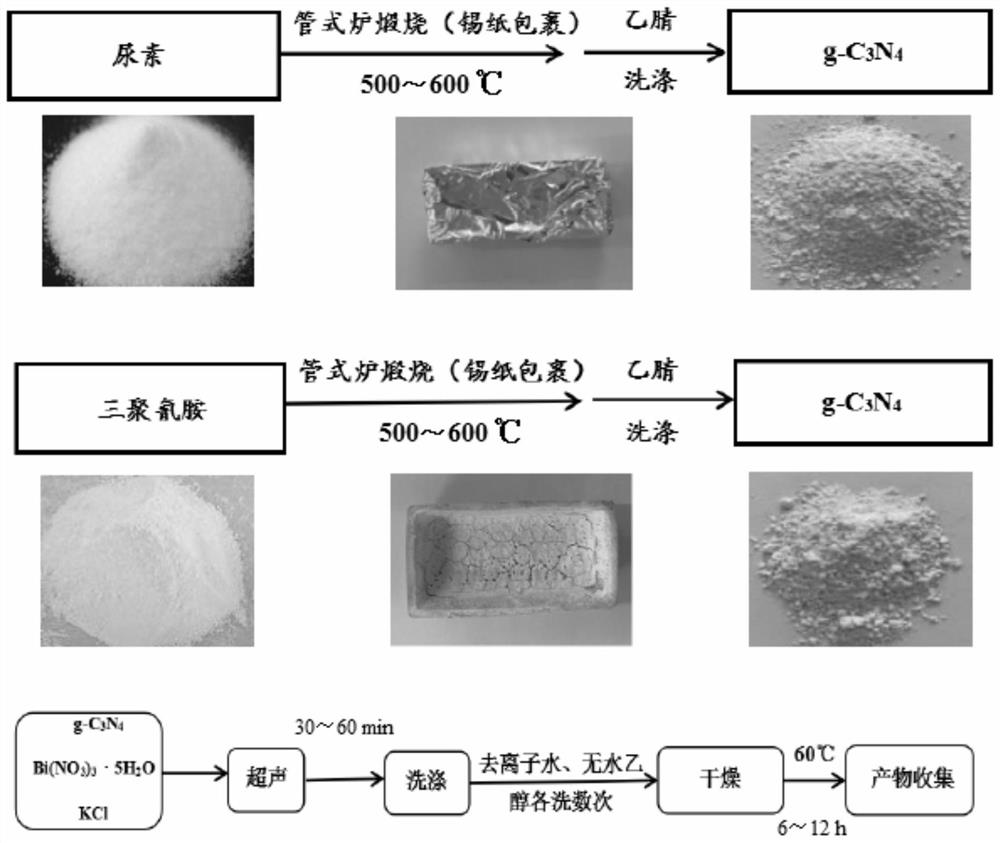

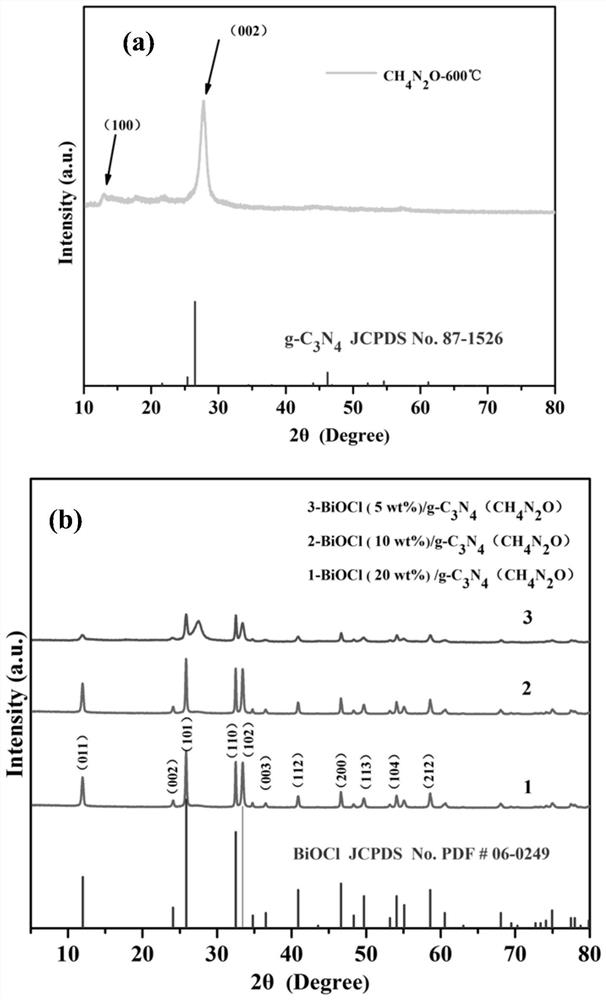

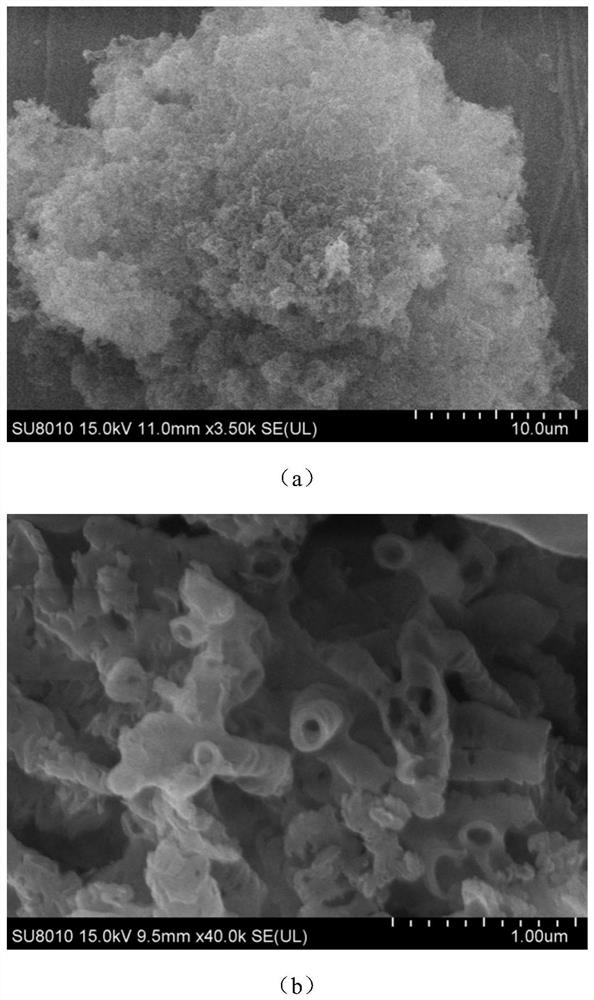

[0033] Porous BiOCl (20wt%) / g-C 3 N 4 Preparation of heterogeneous nanopowder:

[0034] (1) Weigh 5g of urea powder and place it in a quartz boat, then wrap and seal it with tinfoil, push the sample to the central position of the glass tube of the tube furnace with a sampling rod, and place the two tube plugs at the specified position; Set the heating time and holding temperature of the tube furnace, and raise the temperature from room temperature to 515°C with a gradient of 5°C / min, hold for 1 hour, then heat to 600°C with the same gradient, and hold for 1 hour. Cool to room temperature after the reaction, wash and centrifuge the obtained powder product several times with acetonitrile, dry and grind to obtain the desired product.

[0035] (2) First, take 1.6g g-C 3 N 4 Add the powder and 10mL deionized water into a 50mL beaker, and ultrasonically disperse for 1h to obtain g-C 3 N 4 suspension; then sequentially add 0.745g bismuth nitrate pentahydrate and 0.115g potassiu...

Embodiment 2

[0044] Porous rosette BiOCl (10wt%) / g-C 3 N 4 Preparation of heterogeneous nanopowder:

[0045] (1) Weigh 5g of urea powder and place it in a quartz boat, then wrap and seal it with tinfoil, push the sample to the central position of the glass tube of the tube furnace with a sampling rod, and place the two tube plugs at the specified position; Set the heating time and holding temperature of the tube furnace, and raise the temperature from room temperature to 515°C with a gradient of 5°C / min, hold for 1 hour, then heat to 600°C with the same gradient, and hold for 1 hour. Cool to room temperature after the reaction, wash and centrifuge the obtained powder product several times with acetonitrile, dry and grind to obtain the desired product.

[0046] (2) First, take 1.8g g-C 3 N 4 Add the powder and 10mL deionized water into a 50mL beaker, and ultrasonically disperse for 1h to obtain g-C 3 N 4 Suspension; then add 0.373g bismuth nitrate pentahydrate and 0.057g potassium chl...

Embodiment 3

[0049] Porous BiOCl(5wt%) / g-C 3 N 4 Preparation of heterogeneous nanopowder:

[0050] (1) Weigh 5g of urea powder and place it in a quartz boat, then wrap and seal it with tinfoil, push the sample to the central position of the glass tube of the tube furnace with a sampling rod, and place the two tube plugs at the specified position; Set the heating time and holding temperature of the tube furnace, and raise the temperature from room temperature to 515°C with a gradient of 5°C / min. After holding for 1 hour, heat to 600°C with the same gradient and hold for 1 hour. Cool to room temperature after the reaction, wash and centrifuge the obtained powder product several times with acetonitrile, dry and grind to obtain the desired product.

[0051] (2) First, take 1.9g g-C 3 N 4 Add the powder and 10mL deionized water into a 50mL beaker, and ultrasonically disperse for 1h to obtain g-C 3 N 4 suspension; then 0.186g of bismuth nitrate pentahydrate and 0.029g of potassium chloride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com