Method for preparing engineering aggregate by using slag

A technology of engineering bone and slag, applied in the field of engineering aggregate, can solve the problems that the slag cannot be broken into particles of different sizes, the strength of the aggregate is insufficient, and the strength of the engineering aggregate is low, so as to improve the screening quality and screening effect, Improve the strength and hardness, improve the effect of reasonable utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

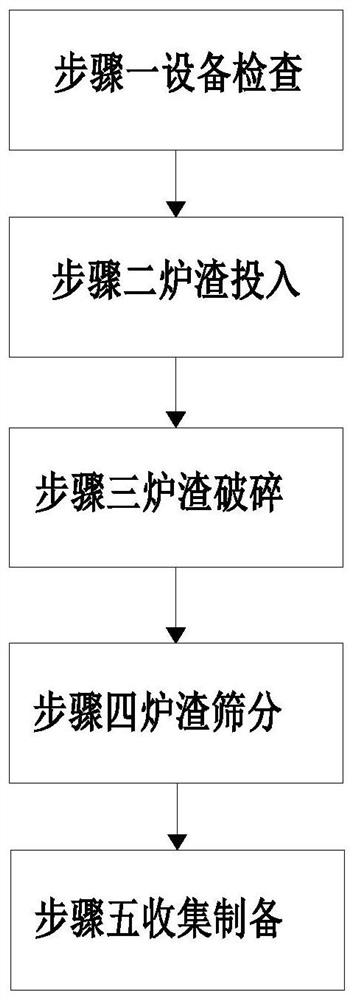

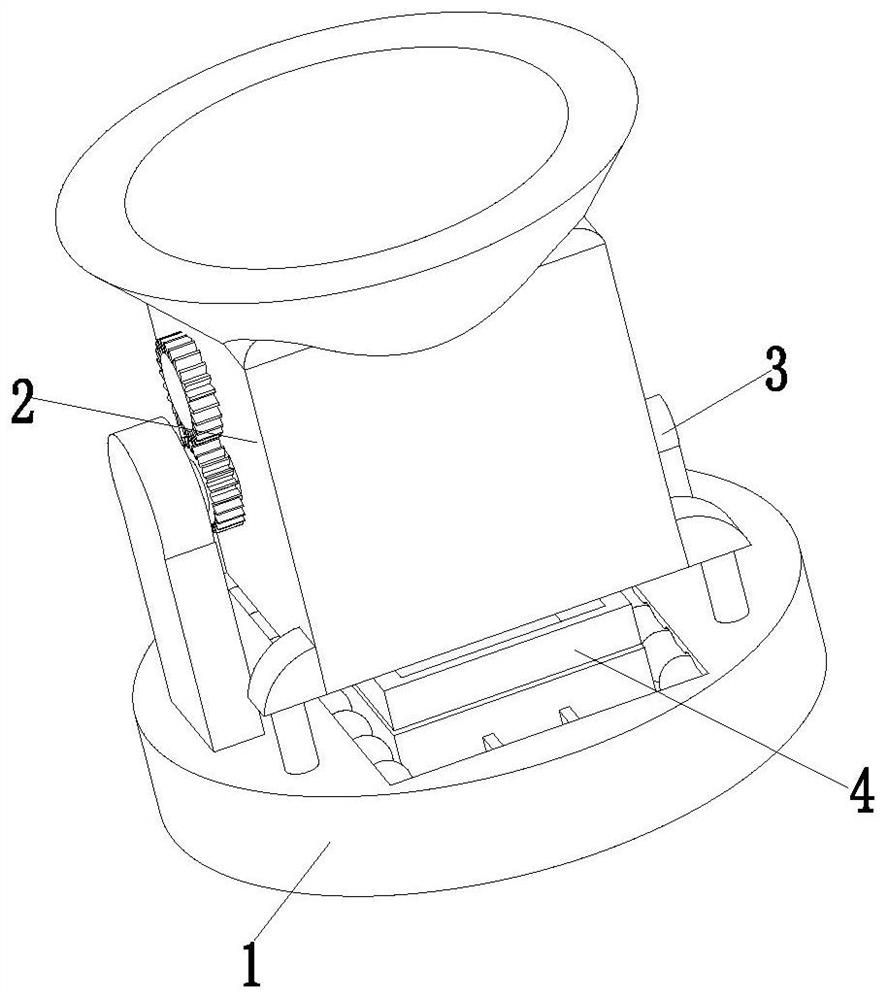

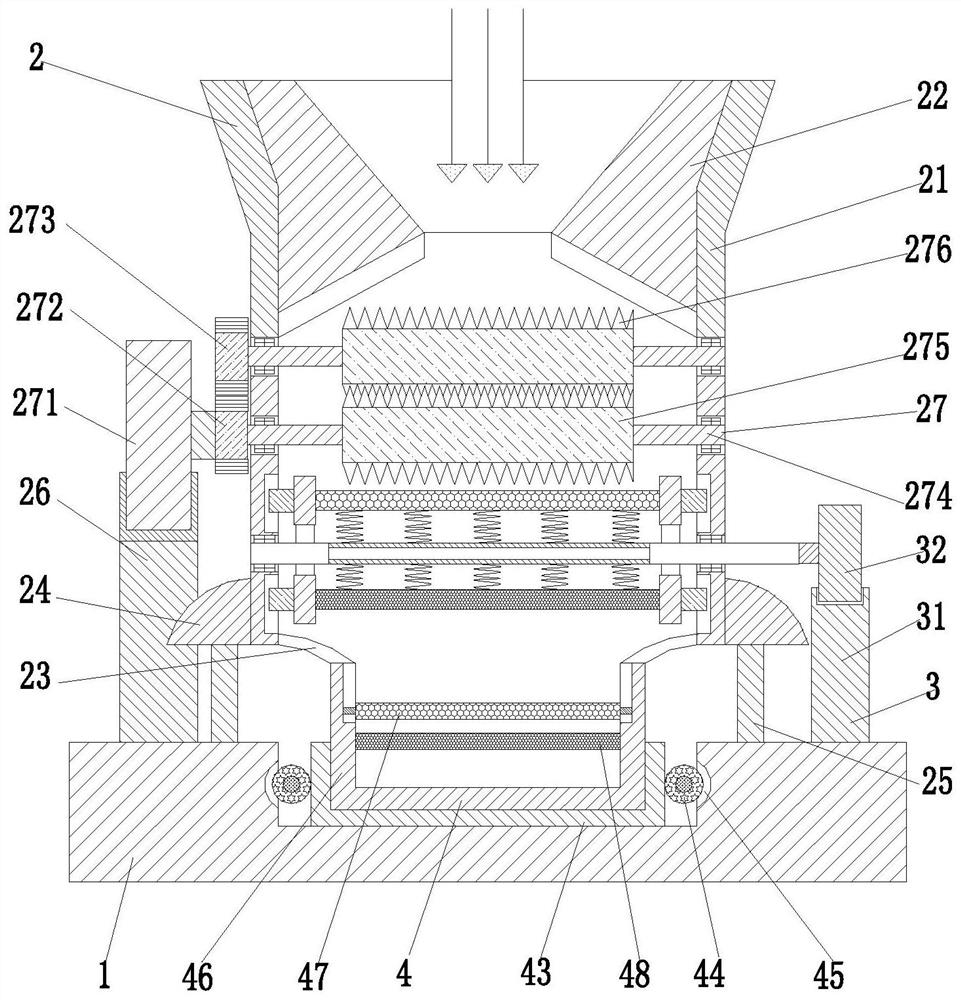

[0036] Such as Figure 1 to Figure 7As shown, a method for preparing engineering aggregates using smelting slag uses an auxiliary equipment for engineering aggregates. The auxiliary equipment for engineering aggregates includes a bottom plate 1, a crushing device 2, a screening device 3 and a collecting Device 4, the bottom plate 1 has a circular structure, a crushing device 2 is installed in the middle of the upper end of the bottom plate 1, a screening device 3 is installed on the crushing device 2, a chute is provided in the middle of the bottom plate 1, and the chute passes A collection device 4 is installed in a sliding fit manner, and the collection device 4 is located below the screening device 3 .

[0037] The crushing device 2 includes a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com