Application of selective inhibitor EDTMPS in magnesite flotation desilicication

A magnesite, selective technology, applied in flotation, solid separation, etc., can solve the problem of low recovery rate of magnesite, achieve good scale inhibition effect, good chemical stability and temperature resistance, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

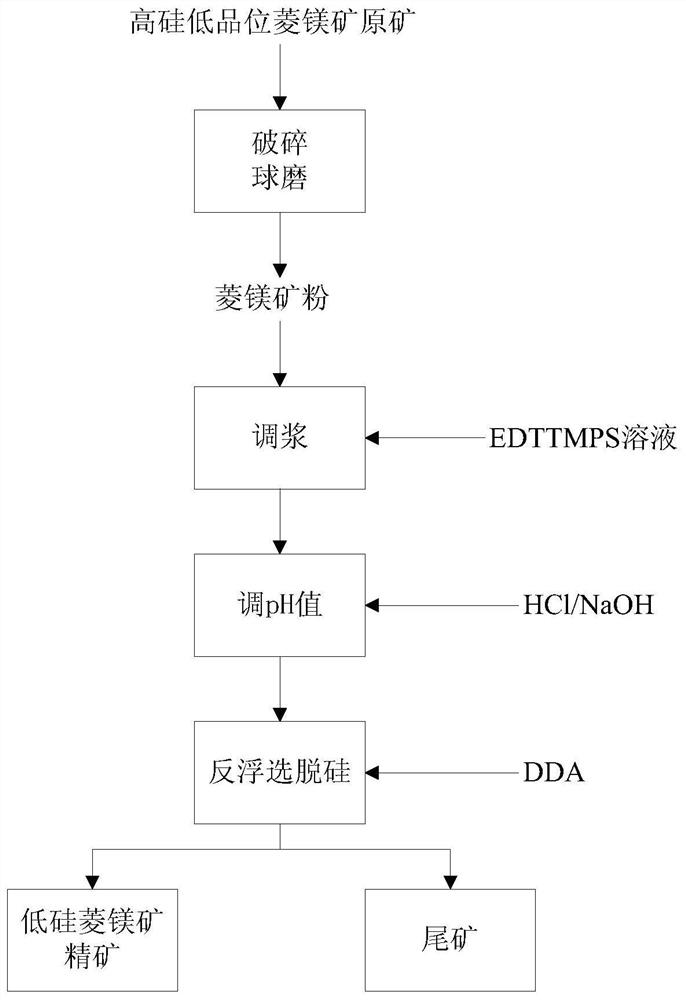

[0037] The application of a selective selective inhibitor EDTMPS in the flotation desilication of magnesite, the process flow diagram is shown in figure 1 , including the following steps:

[0038] Step 1: Grinding

[0039] The high-silicon and low-grade magnesite raw ore is crushed and ball milled to obtain magnesite powder; among them, in the magnesite powder, the mass of magnesite powder with a particle size of less than 74 μm accounts for 70% of the total mass of magnesite powder ;

[0040] Step 2: Blending

[0041] Place the magnesite powder with a particle size of less than 74 μm and accounting for 70% of the total magnesite powder mass in a hanging tank flotation machine, add deionized water and a selective inhibitor EDTTMPS solution, wherein, according to the solid-liquid ratio , Selective inhibitor EDTTMPS: magnesite pulp=80mg: 1L, adjust the hanging tank type flotation machine, the rotating speed is 1800rpm and stir for 2min, make the material mix evenly, carry out...

Embodiment 2

[0047] A kind of application of selective inhibitor EDTMPS in magnesite flotation desilication, comprises the following steps:

[0048] Step 1: Grinding

[0049] The high-silicon and low-grade magnesite raw ore is crushed and ball milled to obtain magnesite powder; among them, in the magnesite powder, the mass of magnesite powder with a particle size of less than 74 μm accounts for 80% of the total mass of magnesite powder ;

[0050] Step 2: Blending

[0051] Place the magnesite powder with a particle size of less than 74 μm and accounting for 80% of the total magnesite powder mass in a hanging tank type flotation machine, add deionized water and a selective inhibitor EDTTMPS solution, wherein, according to the solid-liquid ratio , selective inhibitor EDTTMPS: magnesite pulp=90mg: 1L, and mix uniformly, carry out pulping, obtain magnesite pulp; Wherein, the mass concentration of magnesite in the magnesite pulp is 25%; Selective inhibition The mass concentration of agent EDT...

Embodiment 3

[0057] A kind of application of selective inhibitor EDTMPS in magnesite flotation desilication, comprises the following steps:

[0058] Step 1: Grinding

[0059] The high-silicon and low-grade magnesite raw materials are crushed and ball milled to obtain magnesite powder; among them, in the magnesite powder, the mass of magnesite powder with a particle size of less than 74 μm accounts for 80% of the total mass of magnesite powder ;

[0060] Step 2: Blending

[0061] Place the magnesite powder with a particle size of less than 74 μm and accounting for 80% of the total magnesite powder mass in a hanging tank type flotation machine, add deionized water and a selective inhibitor EDTTMPS solution, wherein, according to the solid-liquid ratio , selective inhibitor EDTTMPS: magnesite pulp=100mg: 1L, and mix uniformly, carry out pulping, obtain magnesite pulp; Wherein, the mass concentration of magnesite in the magnesite pulp is 30%; Selective inhibition The mass concentration of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com