A kind of self-volatility crack paint coating with clear taste and preparation method thereof

A cracked paint and self-volatile technology, applied in the field of coatings, can solve the problems of affecting the appearance, high shrinkage rate of cracked paint, uneven pattern, etc., and achieve the effect of beautiful decorative effect, good adhesion and uniform pattern.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

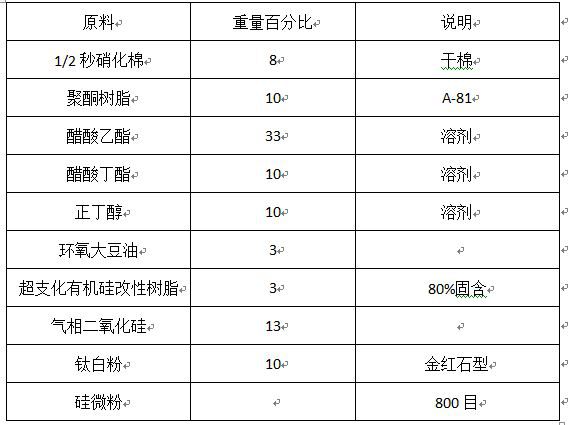

[0046] According to the weight percentage in Table 1.1, add 8% 1 / 2 second nitrocellulose, add 10% polyketone resin.

[0047] Then add ethyl acetate, butyl acetate, n-butanol in turn, soak for 8 hours, and disperse at low speed for 20-30 minutes to make it completely dissolve; stop adding epoxy soybean oil and hyperbranched silicone modified alkyd resin, and disperse at low speed for 10- 15 minutes; in low-speed dispersion, add fumed silica, titanium dioxide, and silicon micropowder respectively, and then disperse at high speed for 20-30 minutes to make the dispersion fineness ≤ 30um, and then the crack paint main agent can be prepared.

[0048] According to the weight percentage in Table 1.2, add ethyl acetate, butyl acetate, n-butanol in turn, divide at a low speed

[0049] Disperse for 10-15 minutes to get crack paint thinner.

[0050] figure 1 It is the main agent of crack paint

[0051] figure 2 crack paint thinner

Embodiment 2

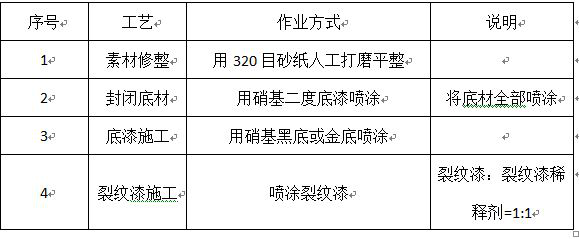

[0053] image 3 It is to apply the above cracked paint on the nitro-based primer: construction process

Embodiment 3

[0055] Figure 4 It is to apply the above crack paint on the PU primer: construction process

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com