Wind turbine blade leading edge protective coating and preparation method thereof

A technology for wind turbine blades and protective coatings, applied in anti-corrosion coatings, coatings, etc., can solve the problems of short service life, poor comprehensive performance, easy aging, etc., and achieve the effects of strong hydrophobicity, good weather resistance, and rich varieties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of a kind of wind power blade leading edge protective coating provided by the present invention is: by weight, 10 parts of absolute ethanol, 3 parts of triethoxymethylsilane and 10 parts of ethoxyphenyl Add the silicone resin into the reaction kettle and stir evenly, adjust the pH value of the reaction solution to about 6 with acid (acetic acid or acrylic acid), and continue to stir at room temperature for about 10 minutes to obtain the silicone resin prepolymer.

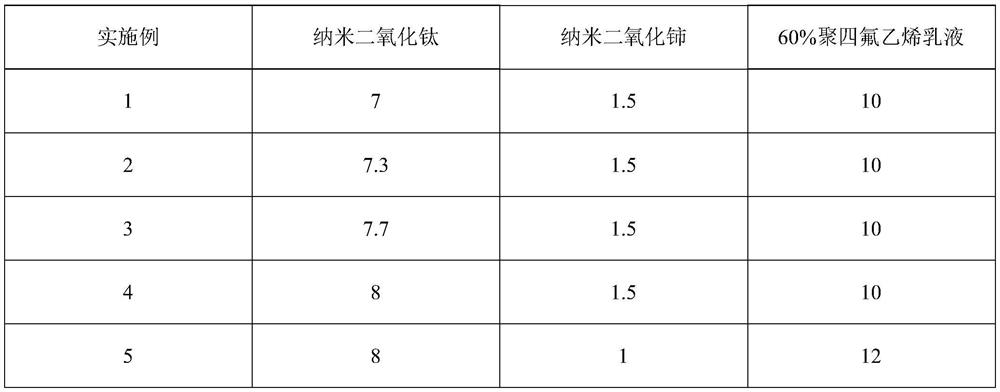

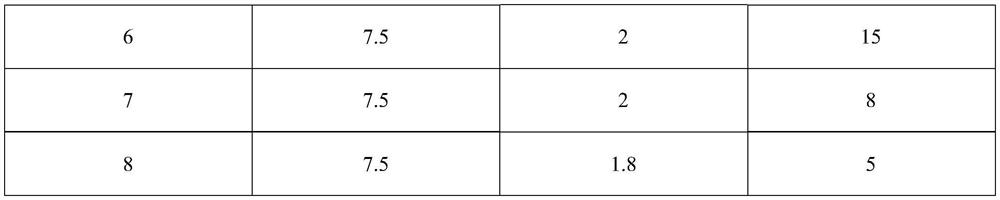

[0029] After mixing 7-8 parts of nano-titanium dioxide, 1-2 parts of nano-cerium oxide, 1 part of acrylic resin and 6 parts of water, put them into a ball mill and grind for about 40 minutes at a speed of 250r / min to obtain functional fillers Dispersions.

[0030] Stir 1 part of silicone resin prepolymer, 1 part of functional filler dispersion and 5-15 parts of polytetrafluoroethylene emulsion (60% solid content) at room temperature for about 15 minutes, then filter with copper mesh to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com