Hydrogen fuel cell, preparation method of hydrogen fuel cell, clamp for preparing hydrogen fuel cell and use method of clamp

A fuel cell and fixture technology, which is used in fuel cells, fuel cell additives, electrolyte treatment of solid electrolyte cells, etc., can solve the problem that hydrogen fuel cells cannot effectively solve the deformation resistance, water flooding resistance, and membrane electrode structure. damage and other problems, to achieve the effect of reducing the structural damage of the catalytic layer, reducing the flooding, and reducing the dispensing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

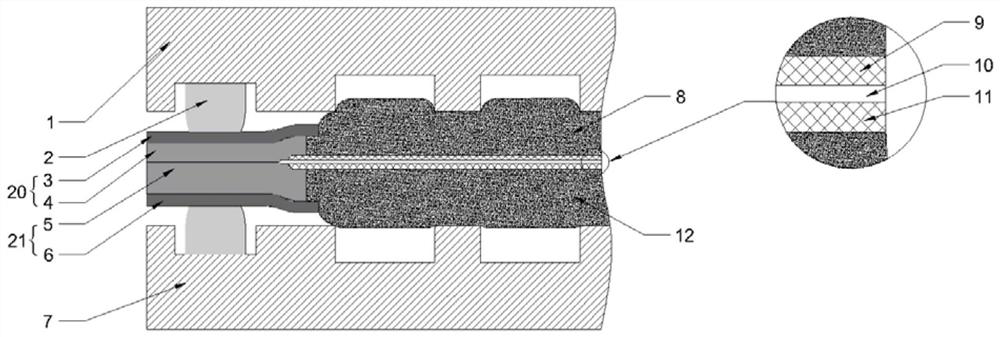

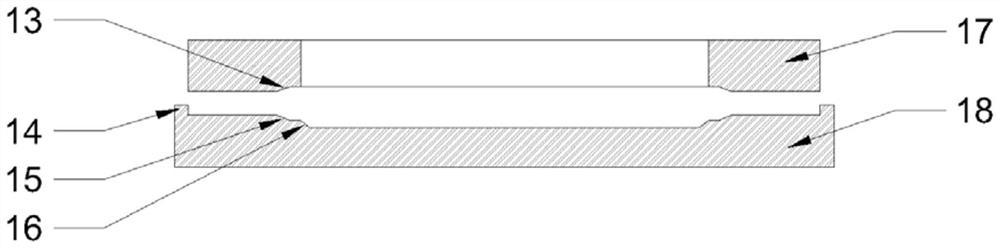

[0114] In another specific embodiment, the present invention provides a method for preparing a hydrogen fuel cell using the above fixture, such as Figure 4 Shown, described preparation method specifically comprises:

[0115] (1) The cathode catalyst slurry and the anode catalyst slurry are applied to the upper and lower surfaces of the proton exchange membrane 10 by spray coating, transfer printing or slit coating, and the cathode catalyst layer 11 and the cathode catalyst layer 11 are formed respectively after drying. The anode catalyst layer 9 is a three-layer membrane electrode.

[0116] (II) Place the lower inner layer frame 5 in the lower plate 18 of the fixture, place the three-layer membrane electrode centered on the lower inner layer frame 5, wherein the cathode catalytic layer 11 is located on the side of the lower inner layer frame 5, and then place the upper inner layer The frame 4 is placed along the outer edge of the three-layer membrane electrode, and finally t...

Embodiment 1

[0120] This embodiment provides a hydrogen fuel cell, based on the hydrogen fuel cell provided in the specific embodiment, wherein the outer dimension of the plane profile of the catalytic layer is less than 1mm of the outer dimension of the plane profile of the proton exchange membrane 10; the gas diffusion layer The outer dimension of the plane profile is less than 2mm of the outer dimension of the plane profile of the catalytic layer; the inner dimension of the plane profile of the upper inner frame and the lower inner frame is smaller than the outer dimension 2mm of the plane profile of the catalytic layer; the upper outer frame 3 and The inner dimension of the plane outline of the lower outer frame 6 is smaller than the outer dimension of the plane outline of the gas diffusion layer by 2mm; the material of the upper outer frame 3 and the lower outer frame 6 is ethylene glycol phthalate; the upper inner frame 4 and the lower inner frame 5 are made of ethylene glycol phthala...

Embodiment 2

[0141] This embodiment provides a hydrogen fuel cell, based on the hydrogen fuel cell provided in the specific embodiment, wherein the outer dimension of the planar profile of the catalytic layer is 1.5mm smaller than the outer dimension of the planar profile of the proton exchange membrane 10; The outer dimension of the plane profile of the layer is 1.5mm smaller than the outer dimension of the plane profile of the catalytic layer; the inner dimension of the plane profile of the upper inner layer frame and the lower inner layer frame is smaller than the outer dimension of the catalytic layer plane profile of 1.5mm; the upper outer layer The inner dimension of the plane profile of the frame 3 and the lower outer frame 6 is smaller than the outer dimension of the plane profile of the gas diffusion layer by 1mm; the material of the upper outer frame 3 and the lower outer frame 6 is polyethylene naphthalate; The upper inner frame 4 and the lower inner frame 5 are made of polyimide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com