Current collector-free battery core and preparation method thereof and lithium ion battery

A technology without current collectors and cells, applied in the field of energy storage, can solve the problems of device stay, complex preparation process and high preparation cost, and achieve the effects of improving work efficiency, good safety and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

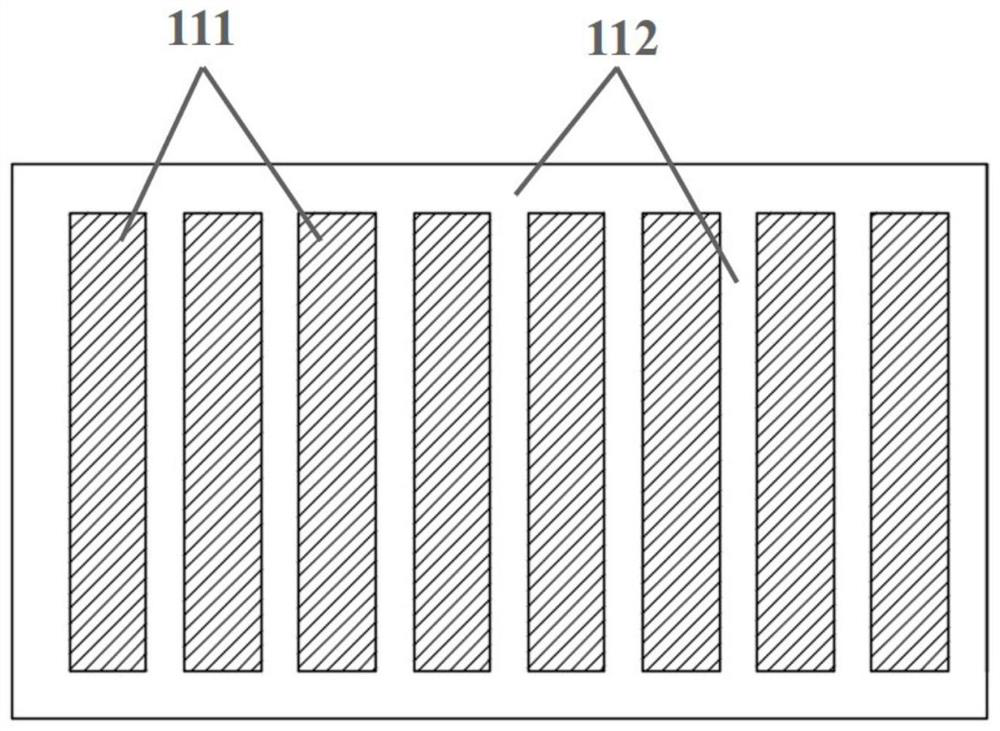

[0094] Step 1, select the positive electrode active material lithium cobaltate, the conductive agent acetylene black and the binder polyvinylidene fluoride to mix and prepare a dry powder, spray the dry powder on the designated area of the hydrophobic and easy-to-peel platform to obtain the positive electrode material layer, Thickness 150μm, surface density 400g / m 2 , specific areas such as figure 1 As shown, including the positive electrode material layer region 111 and the surrounding blank region 112;

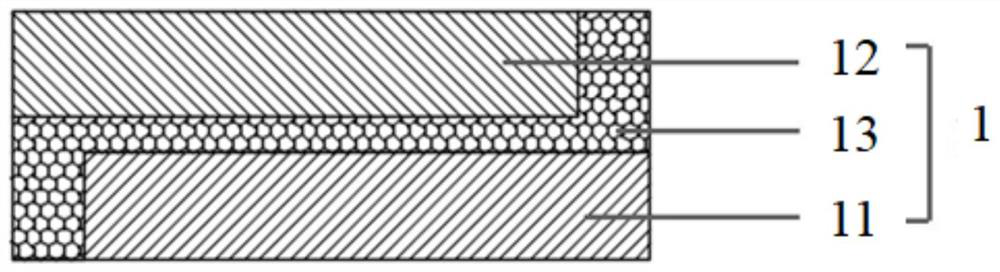

[0095] Step 2, spray the isolation substance material above the positive electrode material layer and the surrounding blank area, specifically the ceramic dielectric material Al 2 o 3 Mix it with the binder polyvinylidene fluoride and the solvent N-methylpyrrolidone to make a slurry, spray it, and get a plane covered with isolation materials again, with a thickness of 30 μm;

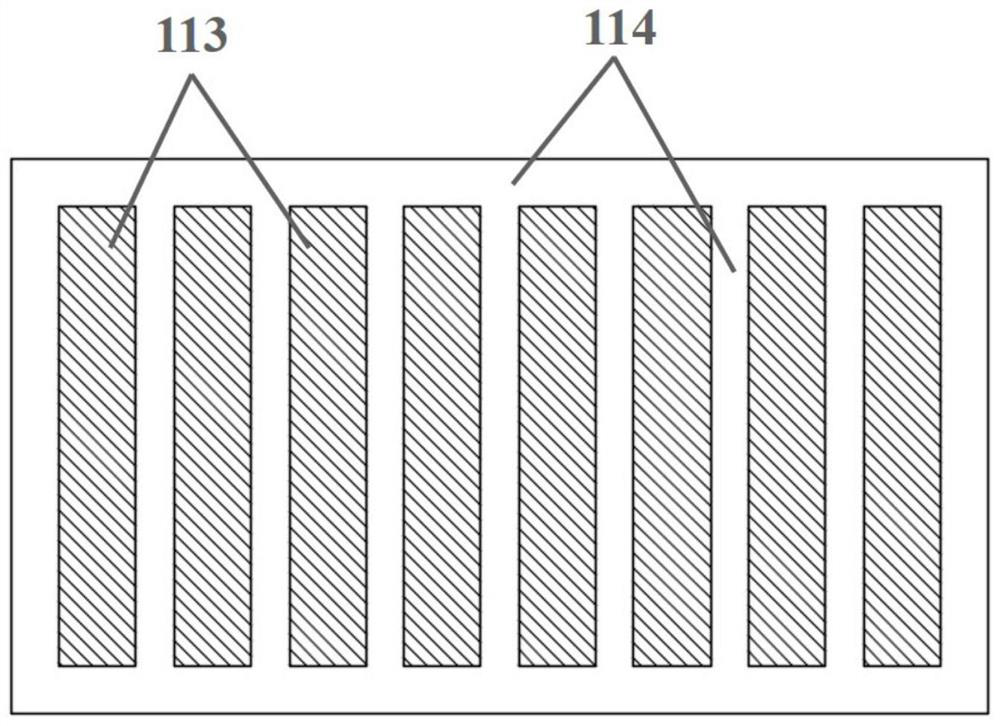

[0096] Step 3: Spray the negative electrode material layer on the designated area above the pl...

Embodiment 2

[0103] A laminated lithium-ion battery cell without a current collector and its manufacturing process according to the present invention, wherein the manufacturing process of the cell is basically the same as in Embodiment 1, except for the difference in specific areas, and the specific steps are as follows:

[0104] Step 1, spraying the positive electrode material layer on the designated area of the hydrophobic and easy-to-peel platform, specific areas such as Figure 4 As shown, including the positive electrode material layer region 211 and the surrounding blank region 212;

[0105] Step 2, spraying the spacer material above the positive electrode material layer and the surrounding blank area, and obtaining a plane covered with the spacer material again;

[0106] Step 3, spray the negative electrode material layer on the designated area above the plane above the above step, the specific area is as follows Figure 5 As shown, it includes the negative electrode material lay...

Embodiment 3

[0113] A laminated lithium-ion battery without a current collector in this embodiment is made of the bare cell prepared in Embodiment 1 and Embodiment 2, and the specific implementation method is as follows:

[0114] First, the cell unit comprising the positive electrode material layer, the negative electrode material layer and the separator material layer obtained in Embodiment 1 and Embodiment 2 is coated with a layer of silver paste on the cut electrode end face;

[0115] Then, the cell is soaked with the electrolyte, so that the cell isolation material layer is filled with the electrolyte;

[0116] Then, assemble the cell filled with the electrolyte and the casing of the corresponding size to obtain a lithium-ion battery.

[0117] In this embodiment, the thickness and surface density of the positive electrode material layer and the negative electrode material layer are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com