Dissolution method of diasporic bauxite

A technology of bauxite and bauxite, applied in chemical instruments and methods, preparation of alkali metal aluminate/aluminum oxide/aluminum hydroxide, aluminum compounds, etc., can solve the problem of large lime consumption and alkali content in effluent red mud High-level problems, to achieve the effect of reducing production economic costs, improving red mud composition, and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

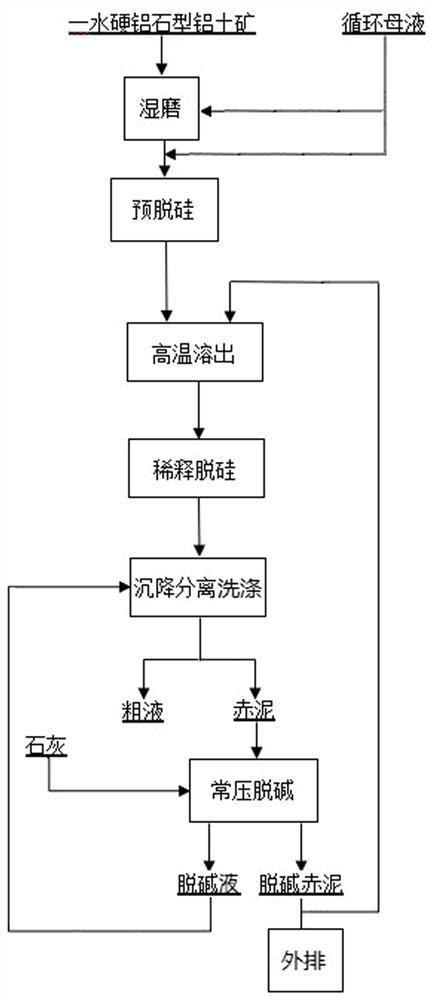

[0028] Dissolution of diaspore ore, the specific operation process is as follows figure 1 As shown, 30g of Shanxi mine A (the specific composition is shown in Table 1) and 60mL of sodium aluminate solution (Na 2 o K : 220g / L, α K : 2.9, alpha K is the molar ratio of sodium oxide to alumina), added to the low-pressure steel bomb, added steel balls to strengthen stirring, and pre-desiliconized at a temperature of 90 ° C for 4 hours (pre-desiliconized bauxite is mixed with the circulating mother liquor, stirred, and kept warm The process of removing silicon from ores). Dissolution red mud mixed with lime, CaO / Na 2 The molecular ratio of O is 4, and the liquid-solid ratio is 4. Take 0.2g of dried dealkalized red mud and pre-desiliconized slurry, mix it into high-pressure steel bombs, replenish the circulating mother liquor to 100ml, dissolve at a temperature of 260°C for 60 minutes, separate the solid-liquid of the dissolved slurry, and the aluminum-silicon ratio of the red m...

Embodiment 2

[0034] The basic content of this embodiment is the same as that of embodiment 1, the difference is that after the red mud is dissolved and mixed with lime, the CaO / Na 2 The molecular ratio of O is 2, and the liquid-solid ratio is 5. Take 0.4g of dried dealkalized red mud and pre-desiliconized slurry and mix it with the high-pressure steel bomb. The dissolution rate is 98.95%.

Embodiment 3

[0036] The content of this example is basically the same as Example 1, except that 30g of Shanxi Mine B (the specific components are shown in Table 1) and 60mL of sodium aluminate solution (Na 2 o K : 230g / L, α K : 3.0), pre-desilicate at a temperature of 95°C for 6 hours, and dissolve at a temperature of 260°C for 70 minutes, the relative dissolution rate of alumina is 96.1%, and the amount of red mud is reduced by 32.5% compared with the traditional lime method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com