Nodular cast iron pipe anti-corrosion lining for conveying drinking water and manufacturing method

A technology for ductile iron pipes and drinking water, which is applied to devices and coatings for coating liquid on the surface, which can solve problems such as human hazards, increased aluminum content in water quality, and increased pH value of small-diameter pipes, so as to improve service life , slow down the dissolution, reduce the effect of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

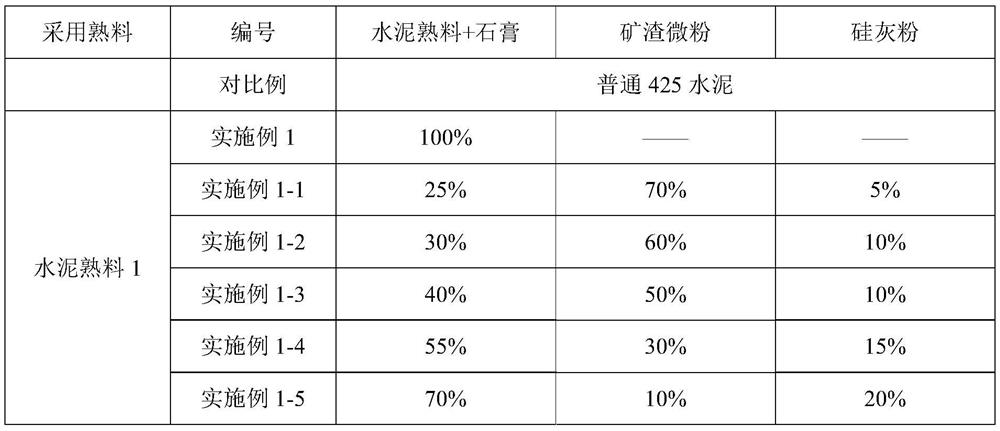

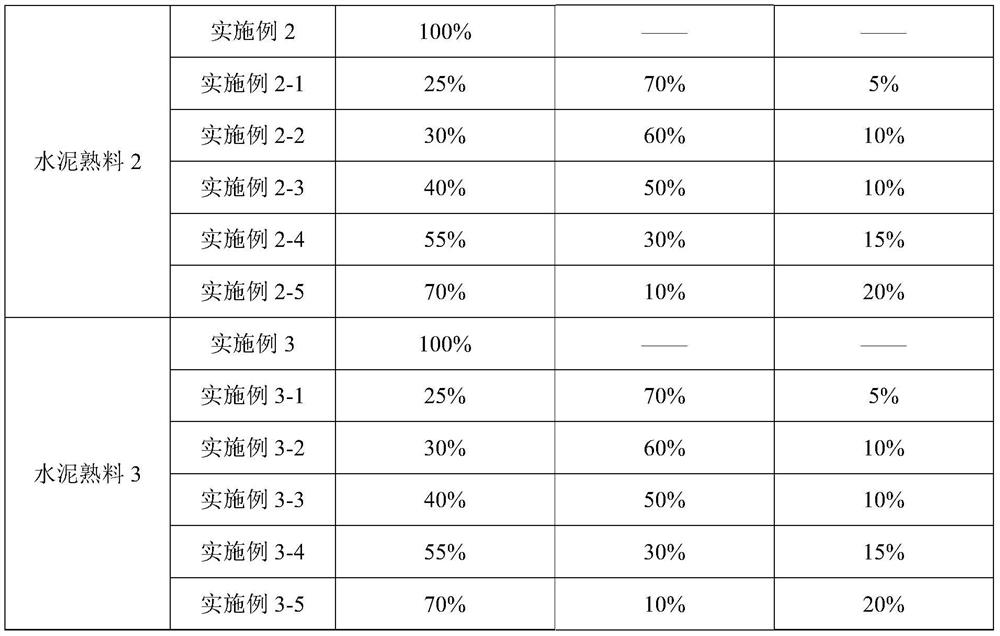

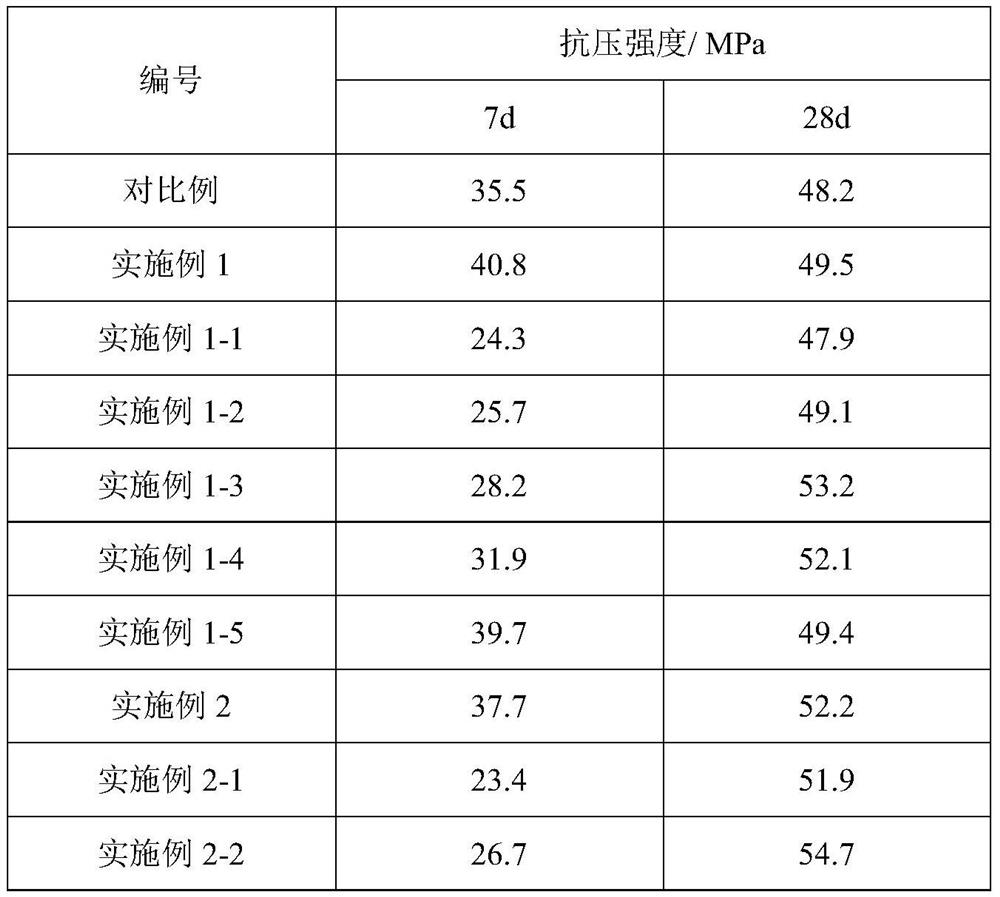

[0027] Detect CaO and SiO according to the method of GB / T 176 2 、Al 2 o 3 , Fe 2 O3, f-CaO, Na 2 O and K 2 O and other chemical components, and then calculate the mineral composition according to the formulas in Table 1 and Table 2 in GB / T21372-2008. Three kinds of cement clinkers with different mineral compositions were selected, and the main mineral compositions and components of each clinker are shown in Table 1 below. Six kinds of cement with different proportions were prepared according to the ratios in Table 2. The speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com