Numerical simulation-based neural network hearth oxygen concentration prediction system and method

A numerical simulation and neural network technology, applied in the field of neural network applications, can solve problems such as insufficient measurement accuracy and low efficiency, and achieve the effects of processing a large amount of information, improving calculation efficiency, and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0044]Specific embodiment one: the neural network prediction furnace oxygen concentration system based on numerical simulation, the system includes a numerical simulation simulation module, a data processing module, an algorithm prediction module and an implementation module, and the above-mentioned modules are connected by a progressive logical relationship, wherein the numerical simulation The simulation module is responsible for establishing the physical model inside the furnace, the data processing module is used to process the numerical simulation results, the algorithm prediction module is responsible for building the double-layer BP neural network model, the MLP neural network model and the DBN neural network model, and the realization module is responsible for selecting the best algorithm In order to realize the prediction of oxygen distribution.

specific Embodiment approach 2

[0045] Specific implementation mode two: the method of predicting the oxygen concentration in the furnace based on the neural network of numerical simulation, for the offline data collected, the physical model of the furnace is established with numerical simulation software, and its grid is divided and the boundary is set in ICEM; using ANSYS FLUENT solves and simulates the divided models to obtain data results; uses data processing methods to process numerical simulation results; uses neural network learning machines to make predictions, and finally realizes the prediction of oxygen distribution inside the furnace, providing theory and practice for the actual operation of boilers basis, including the following steps:

[0046] 1) Numerical simulation: use numerical simulation software to establish a physical model inside the furnace, and perform simulation operations.

[0047] 2) Data processing: processing numerical simulation results.

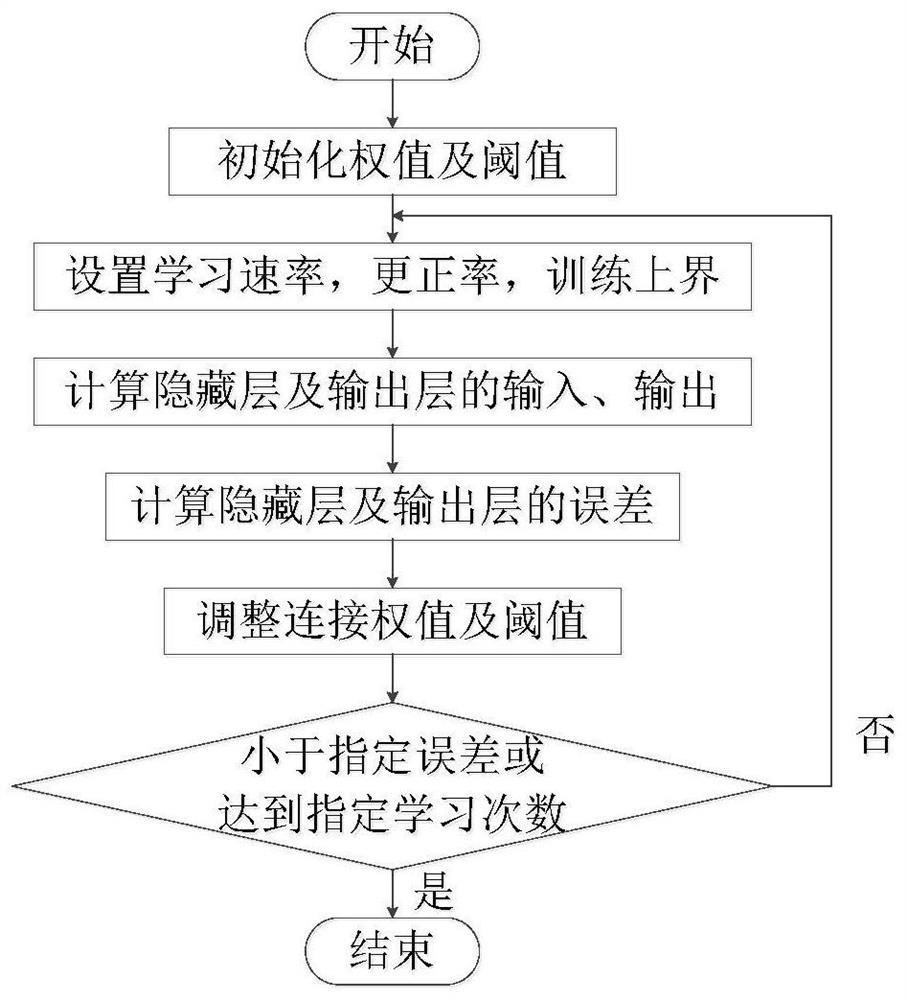

[0048] 3) Algorithm prediction: use t...

specific Embodiment approach 3

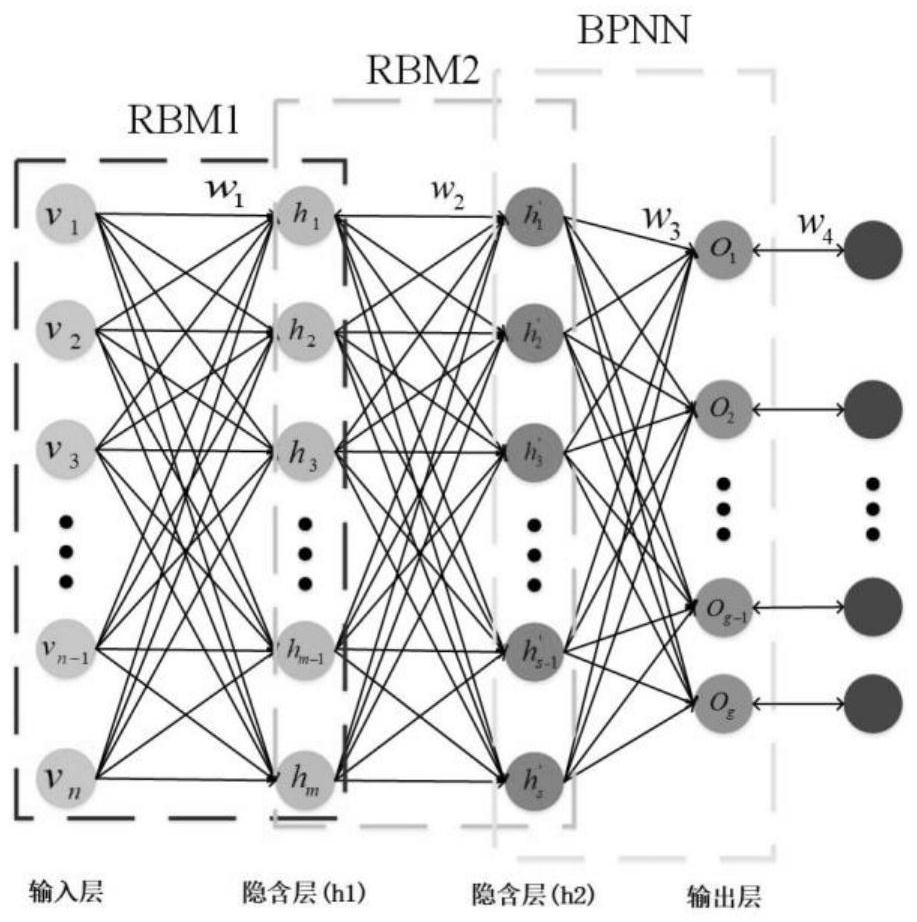

[0067] Specific implementation mode three: In addition to the neural network learning machine described in the first implementation mode, DBN can also be used to predict the oxygen content. The deep belief network (DBN) is composed of multi-layer RBM superposition and the last layer of regression neural network. The data is input through the bottom layer of the model, and passes through the RBM to the hidden layer. The output of the low-level RBM is used as the input of the high-level RBM, such as figure 2 Shown is a DBN model composed of two layers of RBM. The DBN training method firstly uses a bottom-up unsupervised learning method to initialize the parameters of the entire DBN model layer by layer, and then adopts a top-down supervised learning method to fine-tune the network parameters.

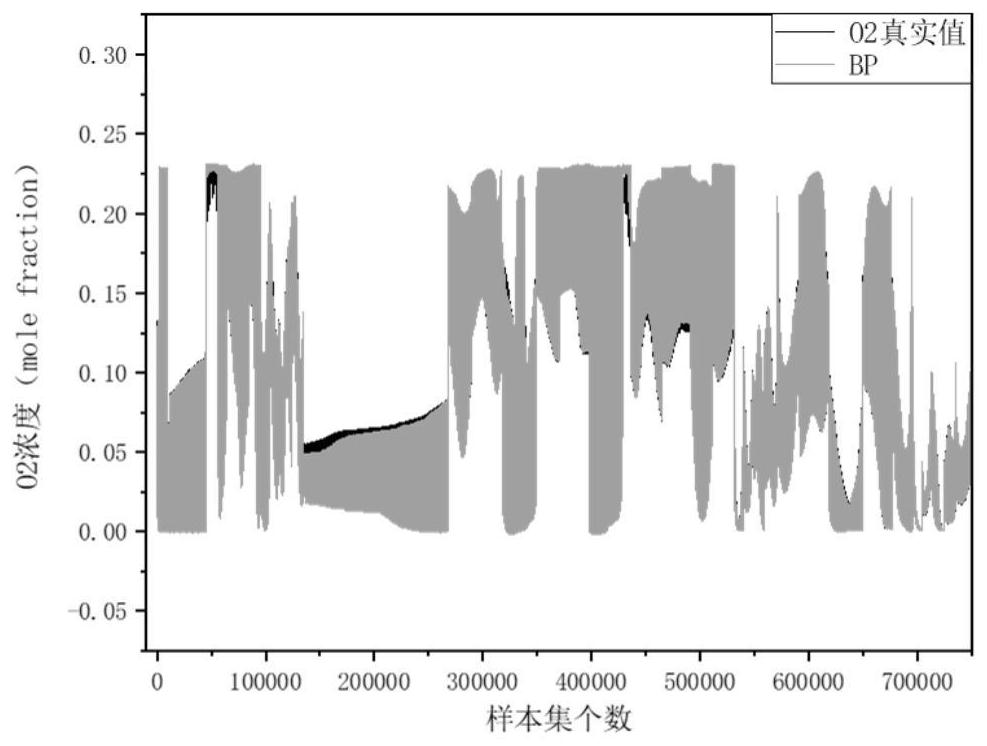

[0068] Write a program to integrate the three algorithms of BP neural network, multi-layer perceptron machine MLP, and deep belief neural network DBN into a neural network learning machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com