NAND ferroelectric storage unit with three-dimensional structure and preparation method thereof

A ferroelectric storage and three-dimensional structure technology, applied in the direction of electrical components, circuits, electric solid devices, etc., can solve problems such as interface layer degradation, achieve the effects of improving fatigue resistance, reducing adverse effects, and reducing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

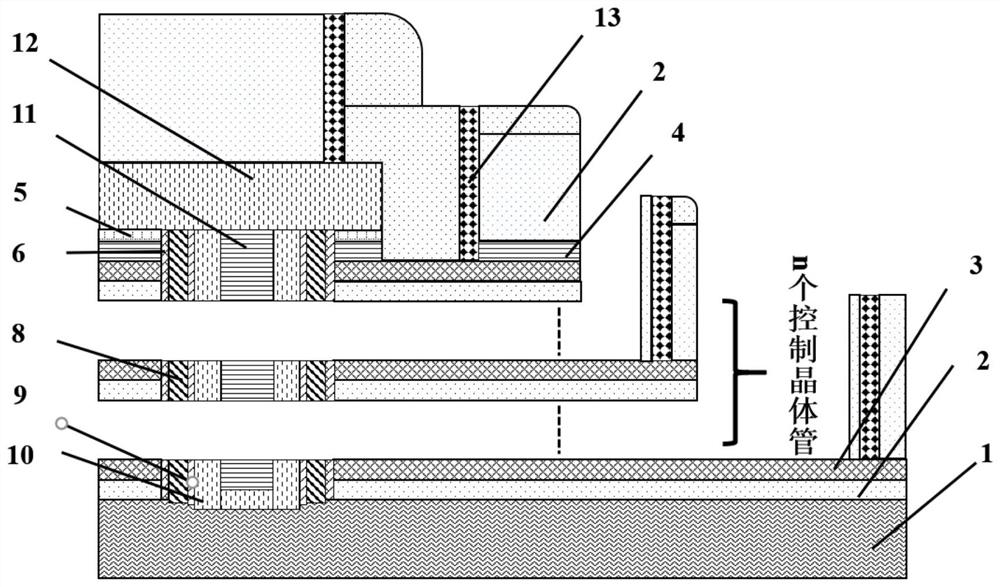

[0028] figure 1 It is a schematic cross-sectional structure diagram of a NAND ferroelectric memory cell with a three-dimensional structure provided in Embodiment 1 of the present invention.

[0029] like figure 1 As shown, the present embodiment provides a NAND ferroelectric memory cell, comprising: an oxide insulating layer, a channel layer, a channel buffer layer, a ferroelectric layer and a gate arranged in sequence from the inside to the outside; the channel A channel buffer layer is arranged between the ferroelectric layer and the ferroelectric layer; and / or, a gate buffer layer is arranged between the ferroelectric layer and the gate. Specifically, an oxide insulating layer, a channel layer, a channel buffer layer, a ferroelectric layer, and a gate buffer layer; or, an oxide insulating layer, a channel layer, a ferroelectric layer, and a gate buffer layer; or, an oxide insulating layer layer, channel layer, channel buffer layer and ferroelectric layer.

[0030] The me...

Embodiment 2

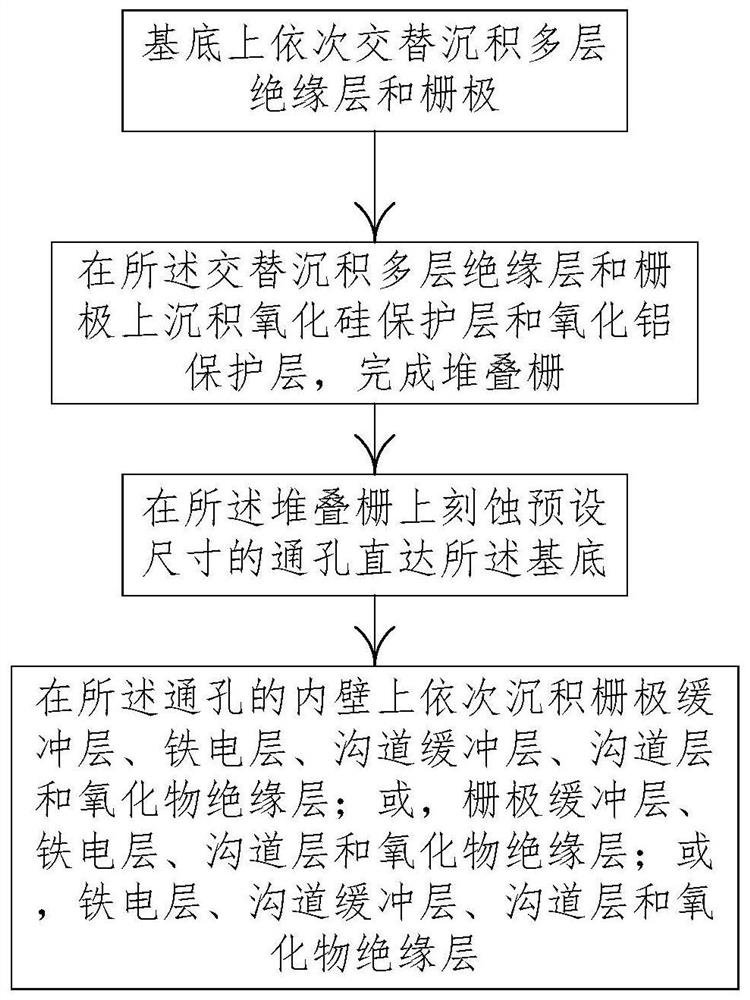

[0040] figure 2 is a flow chart of the manufacturing method of the three-dimensional structure NAND ferroelectric storage unit provided by the second embodiment of the invention.

[0041] like figure 2 It is known that this embodiment provides a method for preparing a NAND ferroelectric memory unit, comprising: sequentially and alternately depositing multiple layers of insulating layers and gates on a substrate; depositing silicon oxide on the alternately deposited multiple layers of insulating layers and gates an insulating layer and an aluminum oxide insulating layer to complete the stacked gate; etching a via hole with a preset size on the stacked gate to reach the substrate; depositing a gate buffer layer, a ferroelectric layer, A channel buffer layer, a channel layer, and an oxide insulating layer; or, a gate buffer layer, a ferroelectric layer, a channel layer, and an oxide insulating layer; or, a ferroelectric layer, a channel buffer layer, a channel layer, and an ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com