Tableted corn fermented feed for crabs as well as preparation method and application of tableted corn fermented feed

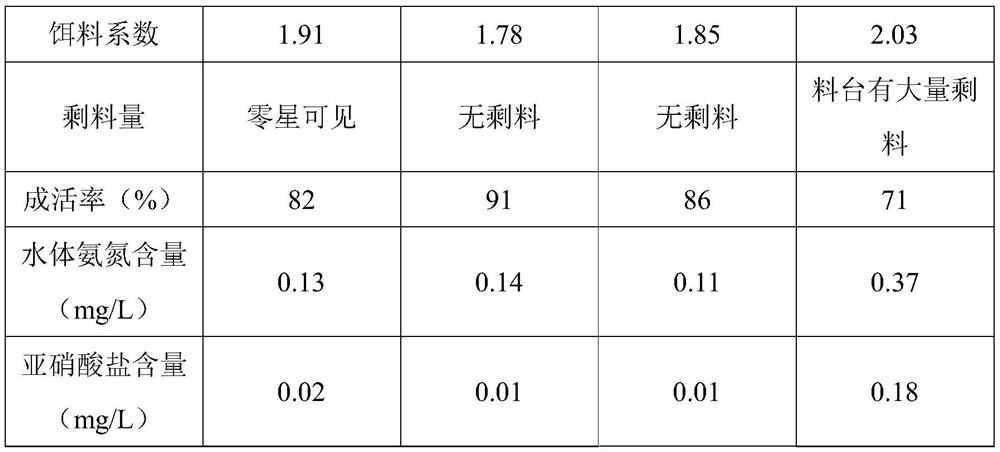

A technology for fermented feed and fermented materials, which is applied to the field of fermented corn fermented feed for crabs and its preparation, can solve the problems of difficulty in pelleting the fermented feed, inconvenience for crabs to eat, poor breeding environment, etc., so as to reduce the bait coefficient and reduce the Food residue, the effect of improving the survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The compressed corn fermented feed for crabs of the present embodiment is made by the following method:

[0032] 1) adding 80 parts of pressed corn into the mixer in parts by weight;

[0033] 2) Weigh 0.02 parts by weight of composite fermentation strains, including Bacillus subtilis, Bacillus coagulans, Streptococcus thermophilus, Lactobacillus acidophilus, Bifidobacterium, Pediococcus pentosaceae, Candida utilis, Saccharomyces cerevisiae , first add warm water at 36°C for activation, and then add 20 parts of water for propagation to obtain a compound beneficial bacteria liquid;

[0034] 3) Spray the compound beneficial bacteria liquid described in 2) on the compressed corn in 1), stir while spraying, and mix evenly;

[0035] 4) Pour the mixture in 3) into a fermenter with a pile height of 20 cm, cover with a film, and carry out anaerobic fermentation for 10 hours;

[0036] 5) Heap the fermented material in 4) to a height of 70 cm, let it stand still, and monitor the...

Embodiment 2

[0038] The compressed corn fermented feed for crabs of the present embodiment is made by the following method:

[0039] 1) adding the flaked corn of 100 parts by weight into the mixer;

[0040] 2) Weigh 0.05 parts by weight of composite fermentation strains, including Bacillus subtilis, Bacillus coagulans, Streptococcus thermophilus, Lactobacillus acidophilus, Bifidobacterium, Pediococcus pentosaceae, Candida utilis, Saccharomyces cerevisiae , first add warm water at 38°C for activation, and then add 45 parts of water for propagation to obtain a compound beneficial bacteria liquid;

[0041] 3) Spray the compound beneficial bacteria liquid described in 2) on the compressed corn in 1), stir while spraying, and mix evenly;

[0042] 4) Pour the mixture in 3) into the fermenter with a heap height of 17 cm, cover it with a film, and carry out anaerobic fermentation for 8 hours;

[0043] 5) Heap the fermented material in 4) to a height of 65 cm, let it stand still, and monitor the ...

Embodiment 3

[0045] The compressed corn fermented feed for crabs of the present embodiment is made by the following method:

[0046] 1) 120 parts by weight of flaked corn are added to the mixer;

[0047] 2) Weigh 0.12 parts by weight of composite fermentation strains, including Bacillus subtilis, Bacillus coagulans, Streptococcus thermophilus, Lactobacillus acidophilus, Bifidobacterium, Pediococcus pentosaceae, Candida utilis, Saccharomyces cerevisiae , first add warm water at 40°C for activation, and then add 40.8 parts of water for propagation to obtain a compound beneficial bacteria liquid;

[0048] 3) Spray the compound beneficial bacteria liquid described in 2) on the compressed corn in 1), stir while spraying, and mix evenly;

[0049] 4) Pour the mixture in 3) into a fermenter with a heap height of 23 cm, cover it with a film, and carry out anaerobic fermentation for 12 hours;

[0050] 5) Heap the fermented material in 4) to a height of 75 cm, let it stand still, and monitor the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com