Multilayer egg roll-shaped composite superhard phase C3N4 nanotube and preparation method thereof

A C3N4, nanotube technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effects of rich surface defect sites, simple and effective process, cheap and non-toxic raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of multi-layer egg roll composite superhard phase C 3 N 4 The preparation method of nanotube, it comprises the following steps:

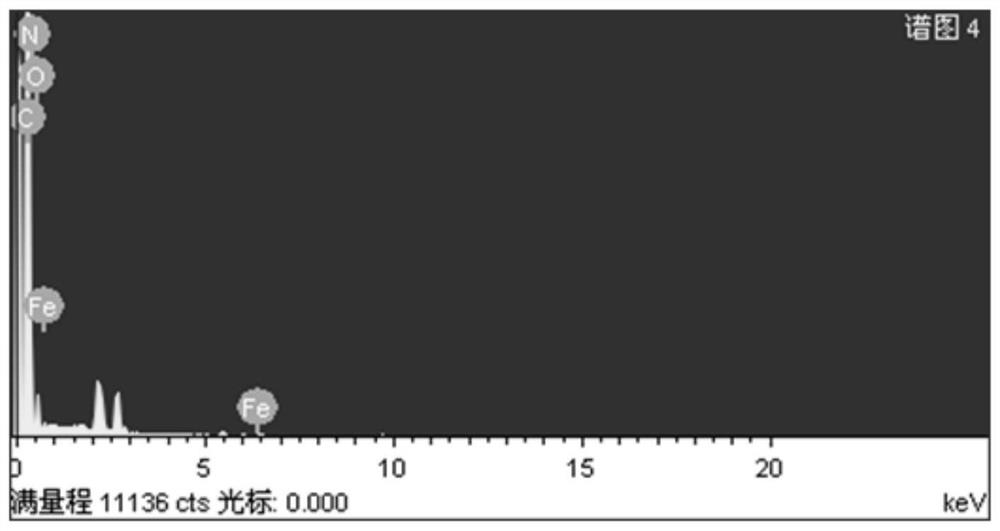

[0032] (1) Weigh 6.01g of CO(NH 2 ) 2 , 1.60g Fe 2 o 3 and 0.73 gMg;

[0033] (2) First, the weighed Mg, Fe 2 o 3 and CO(NH 2 ) 2 After mixing, put it into a stainless steel ball milling tank, the ball milling medium is iron balls, the ratio of ball to material is 30:1; the ball milling tank is sealed and vacuumized, and then 0.1Mpa NH 3 After 6 hours of ball milling, take out the ball abrasive; then put the ball abrasive into the reaction kettle, seal it and put it into a well-type crucible furnace, keep it warm at 600°C for 6 hours, and open the kettle after cooling with the furnace to obtain the crude product;

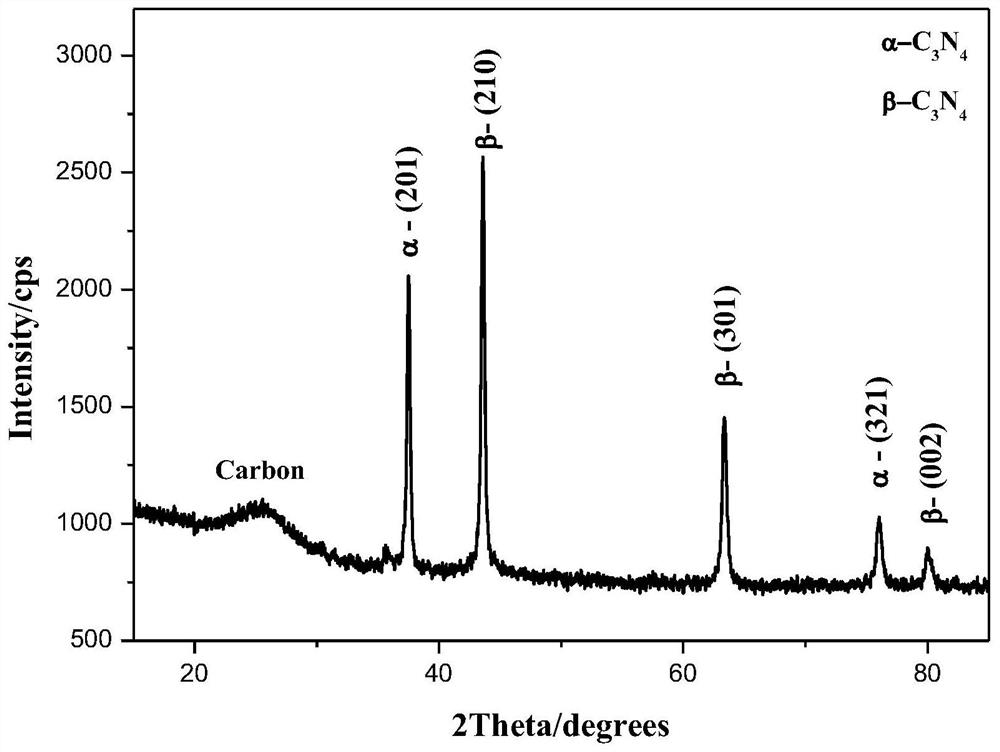

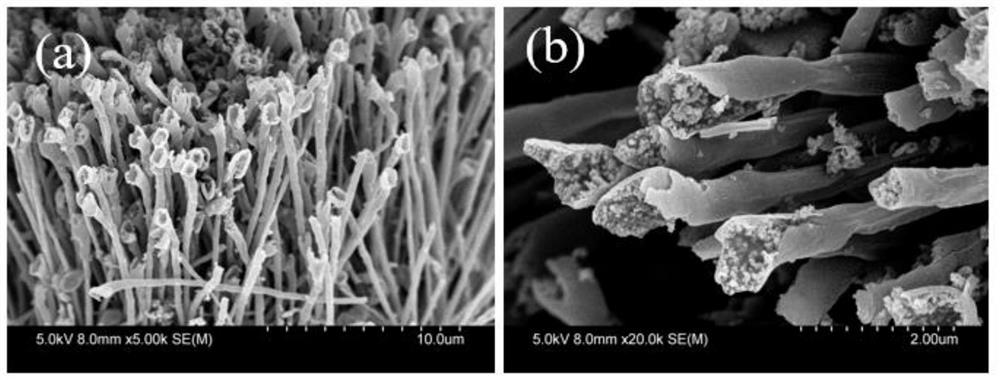

[0034] (3) Disperse the crude product in 5M / L hydrochloric acid, heat and stir at 80°C for 12h, then filter with suction, wash with deionized water and ethanol, and dry in vacuum at 60°C for 12h to obtain a multi-l...

Embodiment 2

[0041] A kind of multi-layer egg roll composite superhard phase C 3 N 4 The preparation method of nanotube, it comprises the following steps:

[0042] (1) Weigh 7.21g of CO(NH 2 ) 2 , 1.25g Fe 2 o 3 and 0.59 gMg;

[0043] (2) First, the weighed Mg, Fe 2 o 3 and CO(NH 2 ) 2 After mixing, put it into a stainless steel ball milling tank, the ball milling medium is iron balls, the ball-to-material ratio is 30:1; seal the ball milling tank, vacuumize it, and then pass 0.3Mpa NH 3 After 4 hours of ball milling, take out the ball abrasive. Then put the ball abrasive into the reaction kettle, seal it and put it into the well-type crucible furnace, keep it warm at 550°C for 6 hours, and open the kettle after cooling with the furnace to obtain the crude product;

[0044] (3) Disperse the crude product in 5M / L hydrochloric acid, heat and stir at 80°C for 12h, then filter with suction, wash with deionized water and ethanol, and dry in vacuum at 60°C for 12h to obtain a multi-la...

Embodiment 3

[0047] A kind of multi-layer egg roll composite superhard phase C 3 N 4 The preparation method of nanotube, it comprises the following steps:

[0048] (1) Weigh 5.71g of CO(NH 2 ) 2 , 1.97g Fe 2 o 3 and 0.92 gMg;

[0049] (2) First, the weighed Mg, Fe 2 o 3 and CO(NH 2 ) 2 After mixing, put it into a stainless steel ball milling tank, the ball milling medium is iron balls, the ratio of ball to material is 30:1; seal the ball milling tank, vacuumize it, and then pass 0.5Mpa NH 3 After 8 hours of ball milling, take out the ball abrasive; then put the ball abrasive into the reaction kettle, seal it and put it into the well-type crucible furnace, keep it at 650°C for 6 hours, and open the kettle after cooling with the furnace to obtain the crude product;

[0050] (3) Disperse the crude product in 5M / L hydrochloric acid, heat and stir at 80°C for 12h, then filter with suction, wash with deionized water and ethanol, and dry in vacuum at 60°C for 12h to obtain a multi-layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Interplanar spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com