Method for promoting microalga growth and oil production by utilizing iron element in flue gas of coal-fired power plant

A coal-fired power plant, iron element technology, applied in the field of microalgae biotechnology and resource recycling, can solve the problems of affecting the growth of microalgae, the decline of microalgae biomass yield, and the adverse effects of microalgae cultivation, so as to promote oil production The effect of increasing the amount and oil production efficiency, promoting improvement, and improving growth and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for transforming and utilizing iron in flue gas of a coal-fired power plant to promote microalgae growth and oil production, comprising the following steps:

[0029] (1) During the microalgae cultivation process, the fly ash particles in the flue gas are washed and collected;

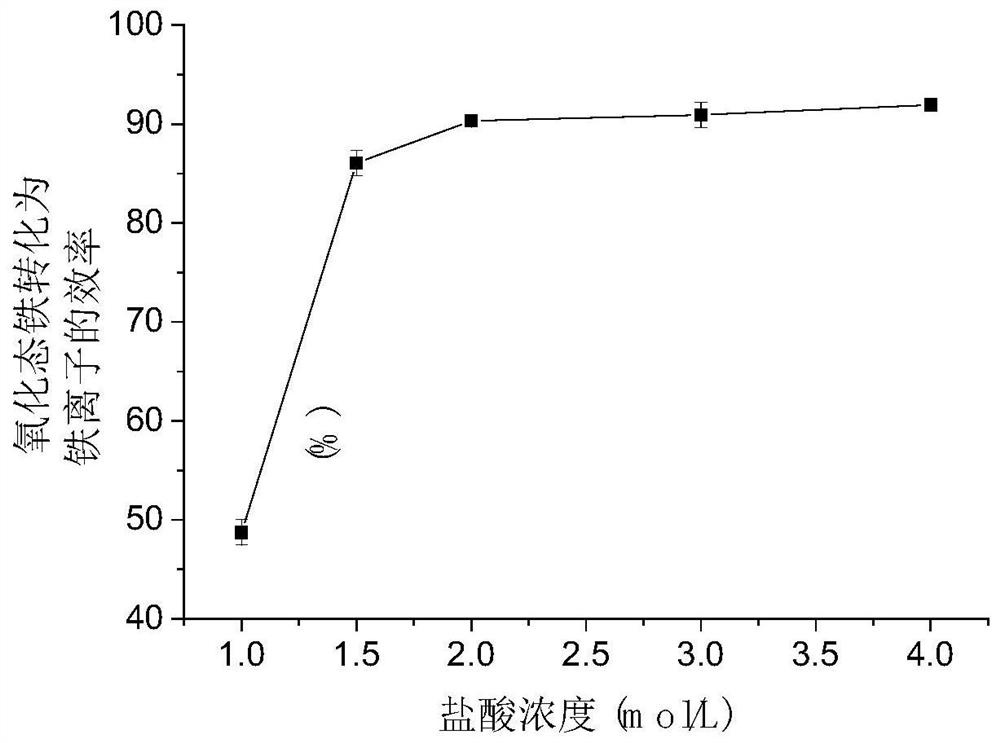

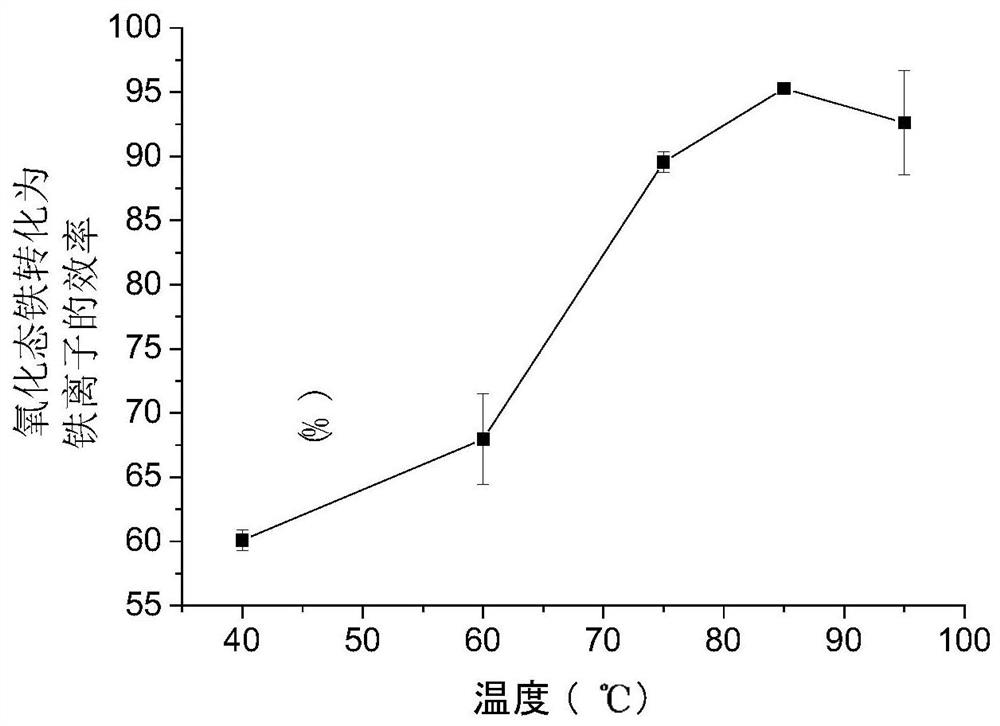

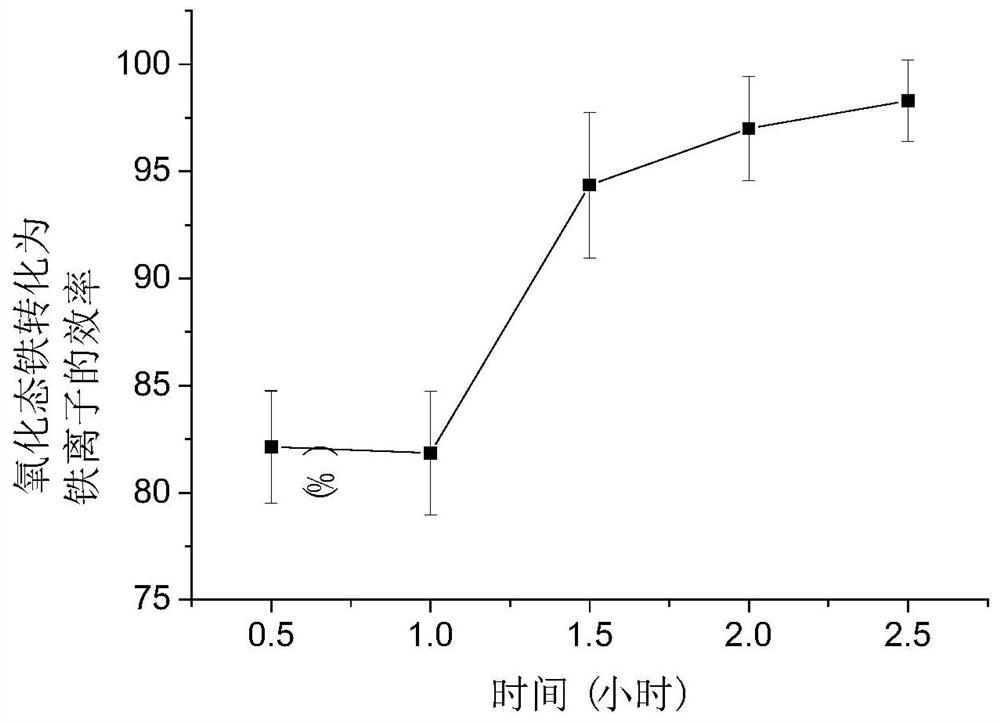

[0030] (2) adding hydrochloric acid to the washed fly ash particles, and reacting to convert the iron oxide particles into ferric ions that can be absorbed and utilized by microalgae;

[0031] (3) get the solution after step (2) reaction and add complexing agent, iron is converted into complexed state iron;

[0032] (4) Add the solution obtained in step (3) into the microalgae culture medium to promote the growth and oil production of the microalgae.

[0033] In step (2), the concentration of hydrochloric acid is 2.0 mol / L, specifically: at the beginning of the reaction in step (2), 5 ml of 2.0 mol / L hydrochloric acid is added to the reaction system.

Embodiment 2

[0047] A method for transforming and utilizing iron in flue gas of a coal-fired power plant to promote microalgae growth and oil production, comprising the following steps:

[0048] (1) During the microalgae cultivation process, the fly ash particles in the flue gas are washed and collected;

[0049](2) adding hydrochloric acid to the washed fly ash particles, and reacting to convert the iron oxide particles into ferric ions that can be absorbed and utilized by microalgae;

[0050] (3) get the solution after step (2) reaction and add complexing agent, iron is converted into complexed state iron;

[0051] (4) Add the solution obtained in step (3) into the microalgae culture medium to promote the growth and oil production of the microalgae.

[0052] Mix nanometer ferric oxide and silicon dioxide particles to simulate the fly ash in the flue gas, and use nanometer ferric oxide to simulate the oxidized iron in the flue gas; take 0.5g of fly ash, and the amount of ferric oxide in ...

Embodiment 3

[0066] A method for transforming and utilizing iron in flue gas of a coal-fired power plant to promote microalgae growth and oil production, comprising the following steps:

[0067] (1) During the microalgae cultivation process, the fly ash particles in the flue gas are washed and collected;

[0068] (2) adding hydrochloric acid to the washed fly ash particles, and reacting to convert the iron oxide particles into ferric ions that can be absorbed and utilized by microalgae;

[0069] (3) get the solution after step (2) reaction and add complexing agent, iron is converted into complexed state iron;

[0070] (4) Add the solution obtained in step (3) into the microalgae culture medium to promote the growth and oil production of the microalgae.

[0071] Mix nanometer ferric oxide and silicon dioxide particles to simulate the fly ash in the flue gas, and use nanometer ferric oxide to simulate the oxidized iron in the flue gas; take 0.5g of fly ash, and the amount of ferric oxide in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com