System for preparing biogas through cooperative treatment of kitchen waste and livestock and poultry manure and preparation method

A technology of biological natural gas and kitchen waste, applied in waste treatment, solid waste removal, etc., can solve the problems of not being able to meet the capacity of large-scale anaerobic fermentation treatment, to avoid odor emission, ensure safety, and wide adaptability of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

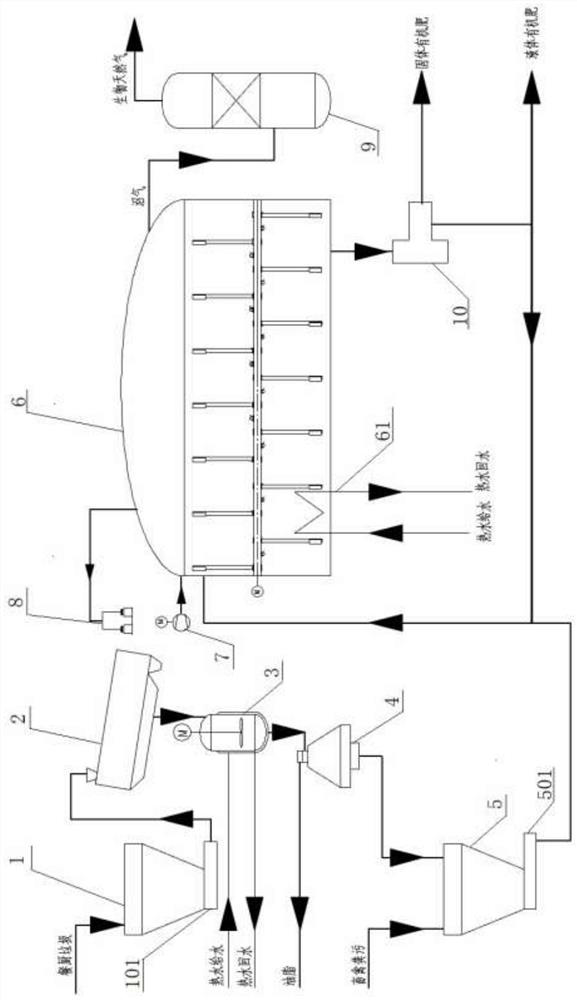

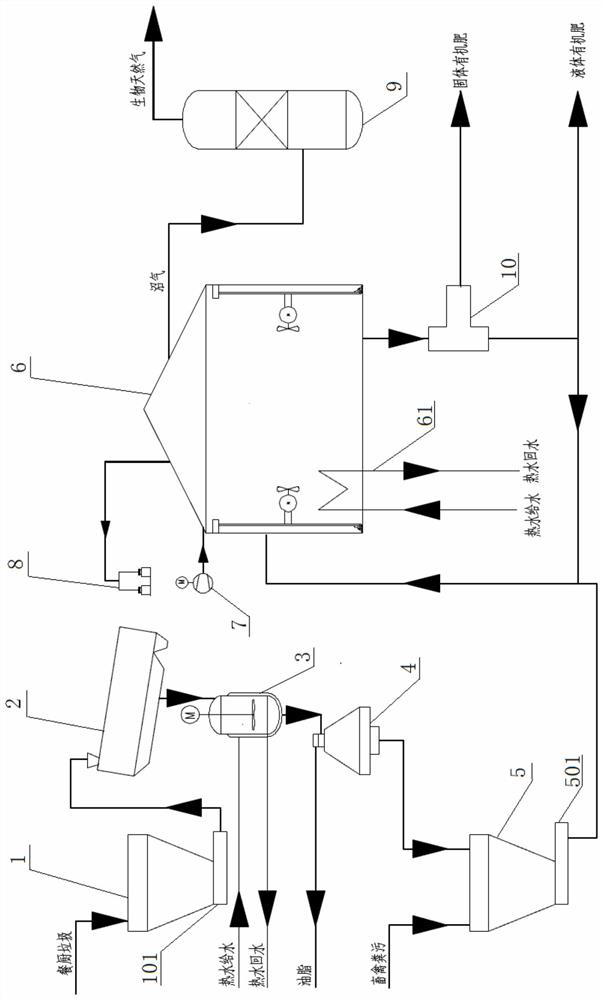

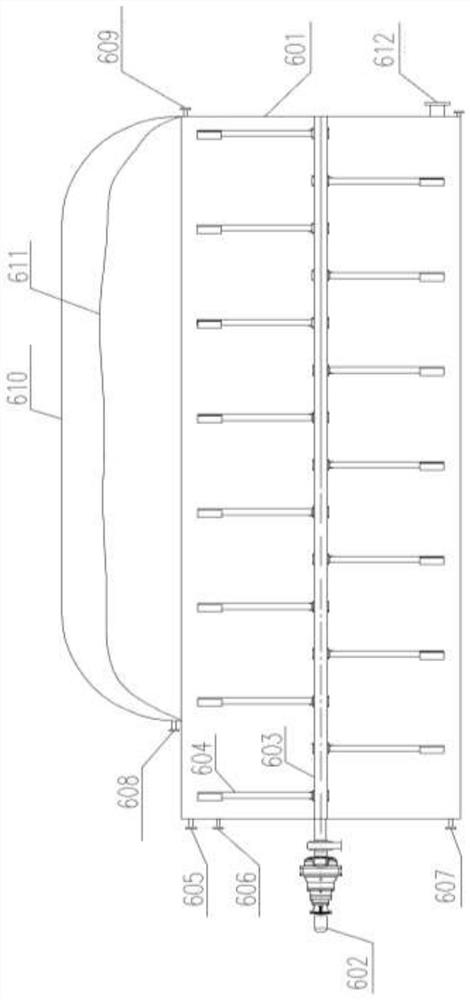

Method used

Image

Examples

Embodiment 1

[0055] Pour 100t of food waste with a solid content of 15% into the food waste silo, and measure it through a weighing and measuring device; send the food waste to the pulping separator for pulping through the screw conveyor installed at the outlet of the silo . Separate the food waste from foreign objects (such as plastics, fruit cores, bones, etc.) through the pulping separator, crush and pulp the food waste after separating the foreign objects, and then use the pump to send the food waste slurry to the oil removal system Heat to remove oil. Heat the temperature of the material to 60°C to 70°C, and separate the grease in the slurry through a centrifugal separation device. The remaining food waste slurry after oil removal is pumped to the mixing silo to be mixed with livestock and poultry manure. The slurry output from the oil removal system is measured by a flow meter, and the output volume is recorded for accurate batching in the mixing silo.

[0056] Send 950t of chicke...

Embodiment 2

[0060] Pour 180t of food waste with a solid content of 15% into the food silo, and measure it through a weighing and measuring device; send the food waste to the pulping separator for pulping through the screw conveyor installed at the outlet of the silo. Separate the food waste from foreign objects (such as plastics, fruit cores, bones, etc.) through the pulping separator, crush and pulp the food waste after separating the foreign objects, and then use the pump to send the food waste slurry to the oil removal system Heat to remove oil. Heat the temperature of the material to 60°C to 70°C, and separate the grease in the slurry through a centrifugal separation device. The remaining food waste slurry after oil removal is pumped to the mixing silo to be mixed with livestock and poultry manure; 600t of livestock and poultry manure mixture with a solid content of 10% is poured into the mixing silo and mixed with the food and kitchen slurry to The TS concentration is 11.2%, the C / N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com