Viscosity-reducing shrinkage-reducing type polycarboxylate superplasticizer

A technology of polycarboxylic acid and water reducer, which is applied in the field of building materials, can solve the problems of shrinkage and crack resistance that cannot meet the performance requirements, insufficient water reducing rate, low compressive strength, etc., achieve good dispersion and dispersion retention, reduce Effect of improving viscosity and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

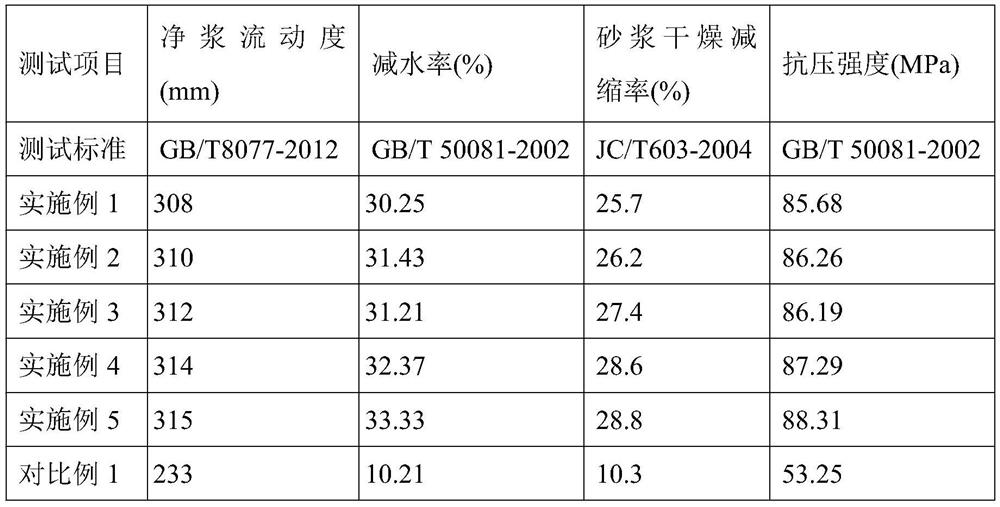

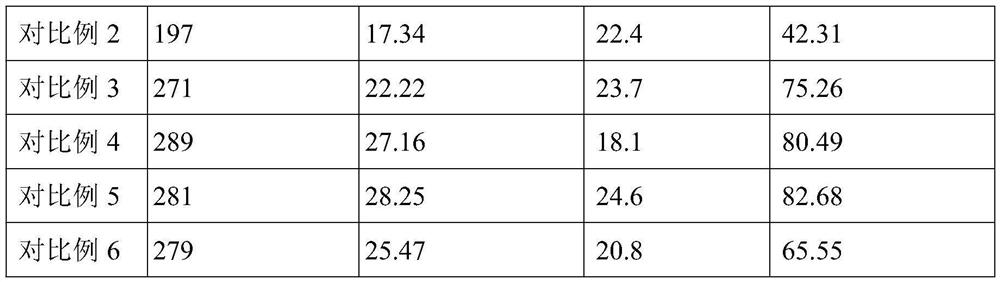

Examples

Embodiment 1

[0029] A viscosity-reducing and shrink-reducing polycarboxylate water-reducer, comprising the following components in mass percent: amino polyether modified silicone / acetone sulfonate formaldehyde condensate / polyacrylic acid 10%, diethylene glycol monovinyl Polyoxyethylene ether / allyl bisquaternary ammonium salt / acrylic acid / (2-propenyl)succinic anhydride copolymer 30%, the balance is water.

[0030] The preparation method of the amino polyether modified organosilicon / acetone sulfonate formaldehyde condensate / polyacrylic acid comprises the following steps: adding amino polyether modified organosilicon / acetone sulfonate formaldehyde condensate and polyacrylic acid to toluene Into the solution, concentrated sulfuric acid was slowly added dropwise, the temperature was raised to 140° C., refluxed for 13 hours, cooled to room temperature, and concentrated to obtain amino polyether modified silicone / acetone sulfonate formaldehyde condensate / polyacrylic acid.

[0031] The molar ratio...

Embodiment 2

[0043] A viscosity-reducing and shrink-reducing polycarboxylate water reducer, comprising the following components in mass percent: amino polyether modified silicone / acetone sulfonate formaldehyde condensate / polyacrylic acid 11%, diethylene glycol monovinyl Polyoxyethylene ether / allyl bisquaternary ammonium salt / acrylic acid / (2-propenyl)succinic anhydride copolymer 29%, the balance is water.

[0044] The preparation method of the amino polyether modified organosilicon / acetone sulfonate formaldehyde condensate / polyacrylic acid comprises the following steps: adding amino polyether modified organosilicon / acetone sulfonate formaldehyde condensate and polyacrylic acid to toluene Into the solution, concentrated sulfuric acid was slowly added dropwise, the temperature was raised to 145° C., refluxed for 14 hours, cooled to room temperature, and concentrated to obtain amino polyether modified silicone / acetone sulfonate formaldehyde condensate / polyacrylic acid.

[0045] The molar ratio...

Embodiment 3

[0057] A viscosity-reducing and shrink-reducing polycarboxylate water reducer, comprising the following components in mass percent: amino polyether modified silicone / acetone sulfonate formaldehyde condensate / polyacrylic acid 13%, diethylene glycol monovinyl Polyoxyethylene ether / allyl bisquaternary ammonium salt / acrylic acid / (2-propenyl)succinic anhydride copolymer 27%, the balance is water.

[0058] The preparation method of the amino polyether modified organosilicon / acetone sulfonate formaldehyde condensate / polyacrylic acid comprises the following steps: adding amino polyether modified organosilicon / acetone sulfonate formaldehyde condensate and polyacrylic acid to toluene Add concentrated sulfuric acid slowly to the solution, raise the temperature to 150°C, reflux for 15 hours, cool to room temperature, and concentrate to obtain amino polyether modified silicone / acetone sulfonate formaldehyde condensate / polyacrylic acid.

[0059] The molar ratio of amino polyether modified s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com