Poly-light heat-insulating plastic concrete for gasification furnace and power station boiler and production process thereof

A power plant boiler and plastic concrete technology, which is applied in the field of refractory materials, can solve the problems of increasing boiler dangerous accidents, difficulty in achieving uniform compaction, and high labor intensity for repairs, so as to achieve convenient construction, prevent sintering cracks, and reduce heating permanent line changes and the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of poly light heat insulation plastic concrete for gasification furnace and power plant boiler, the raw material contains 20% of perlite, 30% of fly ash, 8% of plasticizer, 5% of kyanite, 12% of silicon micropowder in terms of weight percentage, Water glass 25%, based on the above raw materials, plus 0.1% engineering fiber, 0.2% sodium tripolyphosphate, and 0.1% sodium fluorosilicate.

[0026] The production process of the poly-light heat-insulating plastic concrete is as follows: each raw material is weighed according to the proportion, and the perlite, fly ash, plasticizer, silicon micropowder and kyanite are respectively mixed under the condition of 16-35 °C, and stirred for 5-35 °C. 6min, get Mixture 1, set aside; mix sodium tripolyphosphate, water glass, sodium fluorosilicate, engineering fiber, stir for 3-5min, get Mixture 2, set aside; mix Mixture 1 and Mixture 2 again, After stirring evenly, put it into a packaging bag and set it aside.

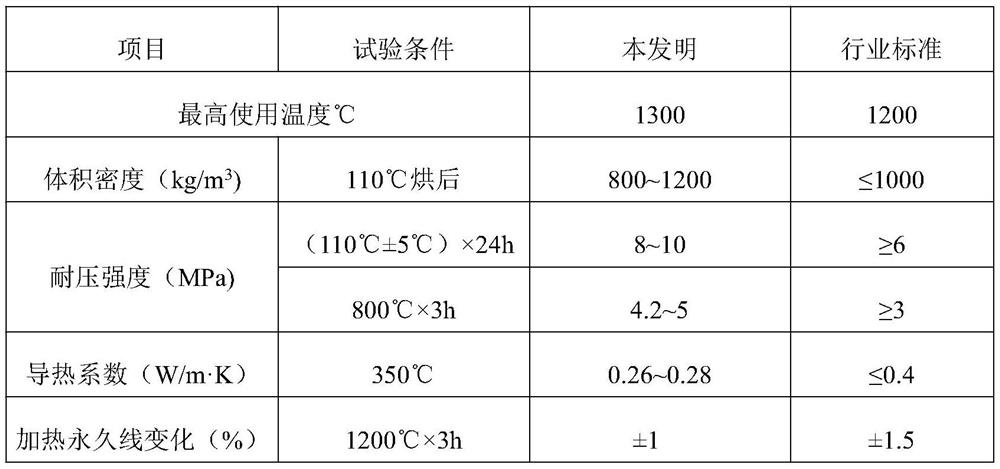

[0027] The poly...

Embodiment 2

[0029] A kind of poly light-weight thermal insulation plastic concrete for gasification furnace and power plant boiler, the raw material contains 25% of perlite, 30% of fly ash, 10% of plasticizer, 5% of kyanite, 5% of silicon micropowder in weight percentage, Aluminum sulfate 25%, based on the above raw materials, plus 0.15% engineering fiber, 0.15% sodium tripolyphosphate, and 0.1% sodium fluorosilicate.

[0030] The production process of the poly-light heat-insulating plastic concrete is as follows: each raw material is weighed according to the proportion, and the perlite, fly ash, plasticizer, silicon micropowder and kyanite are respectively mixed under the condition of 16-35 °C, and stirred for 5-35 °C. 6min, get mixture 1, set aside; mix sodium tripolyphosphate, aluminum sulfate, sodium fluorosilicate, engineering fiber, stir for 3-5min, get mix 2, set aside; then mix mix 1 and mix 2, After stirring evenly, put it into a packaging bag and set it aside.

[0031] The poly...

Embodiment 3

[0033] A kind of poly light heat insulation plastic concrete for gasification furnace and power plant boiler, the raw material contains 25% of perlite, 35% of fly ash, 8% of plasticizer, 3% of kyanite, 5% of silicon micropowder in weight percentage, Aluminum sulfate 24%, based on the above raw materials, plus 0.1% engineering fiber, 0.2% sodium tripolyphosphate, and 0.15% sodium fluorosilicate.

[0034] The production process and application method of the poly-light heat-insulating plastic concrete are the same as those in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com