Seaweed rice seedbed conditioner and preparation method thereof

A conditioner and rice seedling technology, which is applied in the field of seaweed rice seedbed conditioner and its preparation, can solve the problems of soil fertility decline, resistance deterioration, and vigorous growth of seedlings, so as to restore soil fertility, satisfy quick-acting and long-acting Sexual absorption, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

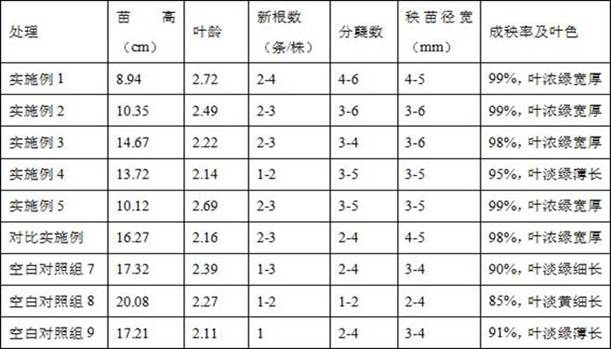

Examples

Embodiment 1

[0021] A seaweed rice seedbed conditioner, prepared from the following raw material components in parts by weight: 120 parts of decomposed enteromorpha, 10 parts of oyster powder, 570 parts of ammonium sulfate, 140 parts of monoammonium phosphate, 55 parts of potassium sulfate, sulfonated humic acid 80 parts of acid, 6 parts of zinc sulfate monohydrate, 7 parts of manganese sulfate monohydrate, 1 part of microbial agent, 10 parts of ferrous sulfate, 1 part of paclobutrazol;

[0022] The decomposed Enteromorpha is prepared by the following method: Enteromorpha powder: water = 1:1, add 0.2% decomposed bacteria agent, mix evenly, decompose for 20-30 days, measure the temperature regularly, if the high temperature does not drop, turn over Heap processing.

[0023] The above-mentioned decomposing bacteria agent is EM bacteria agent.

[0024] The microbial agent above is a mixed agent of Geobacillus stearothermophilus LJ-2 and Bacillus methylotrophicus LJ, the mass ratio of which i...

Embodiment 2

[0028] A seaweed rice seedbed conditioner, prepared from the following raw material components in parts by weight: 140 parts of decomposed enteromorpha, 8 parts of oyster powder, 580 parts of ammonium sulfate, 120 parts of monoammonium phosphate, 60 parts of potassium sulfate, sulfonated humic acid 90 parts of acid, 7 parts of zinc sulfate monohydrate, 8 parts of manganese sulfate monohydrate, 2 parts of microbial agent, 12 parts of ferrous sulfate, 1.2 parts of paclobutrazol;

[0029] The decomposed Enteromorpha is prepared by the following method: Enteromorpha powder: water = 1:1, add 0.2% decomposed bacteria agent, mix evenly, decompose for 20-30 days, measure the temperature regularly, if the high temperature does not drop, turn over Heap processing.

[0030] The above-mentioned decomposing bacteria agent is EM bacteria agent.

[0031] The microbial agent above is a mixed agent of Geobacillus stearothermophilus LJ-2 and Bacillus methylotrophicus LJ, the mass ratio of whic...

Embodiment 3

[0035] A seaweed rice seedbed conditioner, prepared from the following raw material components in parts by weight: 120 parts of decomposed enteromorpha, 10 parts of oyster powder, 570 parts of ammonium sulfate, 140 parts of monoammonium phosphate, 55 parts of potassium sulfate, sulfonated humic acid 80 parts of acid, 6 parts of zinc sulfate monohydrate, 7 parts of manganese sulfate monohydrate, 1 part of microbial agent, 10 parts of ferrous sulfate, 1 part of paclobutrazol;

[0036] The decomposed Enteromorpha is prepared by the following method: Enteromorpha powder: water = 1:1, add 0.2% decomposed bacteria agent, mix evenly, decompose for 20-30 days, measure the temperature regularly, if the high temperature does not drop, turn over Heap processing.

[0037] The above-mentioned decomposing bacteria agent is EM bacteria agent.

[0038] The above-mentioned microbial agent is Geobacillus stearothermophilus LJ-2, and the preservation number is CGMCC NO.7572;

[0039] Preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com