Preparation method of bromobenzene

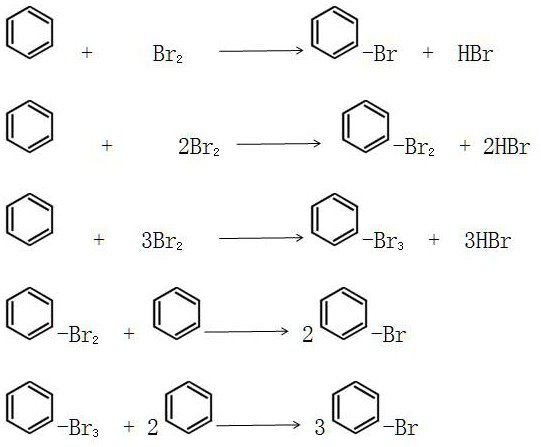

A technology of bromobenzene and dibromobenzene, which is applied in the field of preparation of bromobenzene, can solve problems such as increased reaction cost, unsuitability for industrial production, and complex processing, and achieves the effects of low environmental pollution, low price, and simple synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

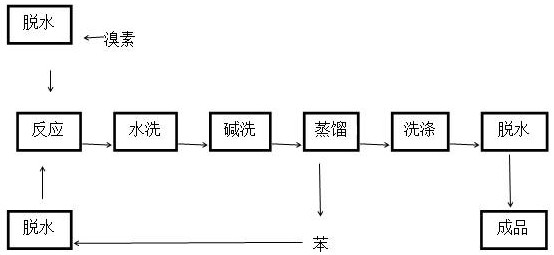

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of bromobenzene, the preparation steps are as follows: (1) Add benzene into the reaction vessel, add catalyst A into the reaction vessel under stirring, then add bromine dropwise, heat up and reflux; (2) Add benzene to the reaction vessel Add Catalyst B and benzene to the reaction solution, and return to the reaction solution where the total content of dibromobenzene is less than 3%, and the total content of tribromobenzene is less than 0.3%; Add water to the distillation pot for distillation, first distill off the unreacted benzene, and then collect the fraction at 155-157°C, which is bromobenzene.

Embodiment 2

[0022] On the basis of Example 1, the catalyst A is a mixture of one or more of iron powder, ferric chloride, aluminum chloride, Lewis acid; the addition of the catalyst A is 0.5% of the bromine quality -3%; the catalyst B is aluminum trichloride; the addition of the catalyst B is 3-5% of the mass of bromine.

Embodiment 3

[0024] On the basis of Example 2, when the catalyst A and the catalyst B are the same substance, it is not necessary to separate the catalyst A before adding the catalyst B; if the catalyst A and the catalyst B are different substances, it is necessary to stand the reaction liquid Catalyst B is added after catalyst A is separated; the separated catalyst A can be recycled for step (1) after being sealed and preserved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com