Low-temperature reaction type high-temperature-resistant coating and preparation method thereof

A high-temperature-resistant coating and low-temperature reaction technology, which is applied in the direction of fire-proof coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of inconvenient construction and long curing time, and achieve good salt spray resistance, excellent comprehensive performance, and excellent performance. The effect of long-term high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

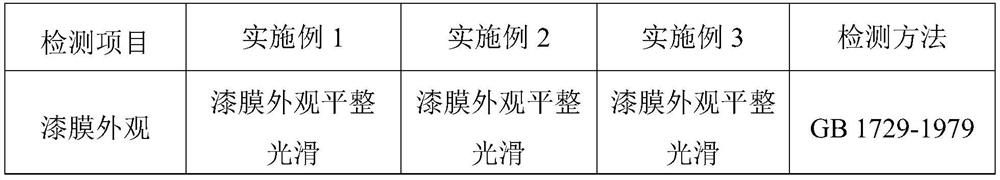

Embodiment 1

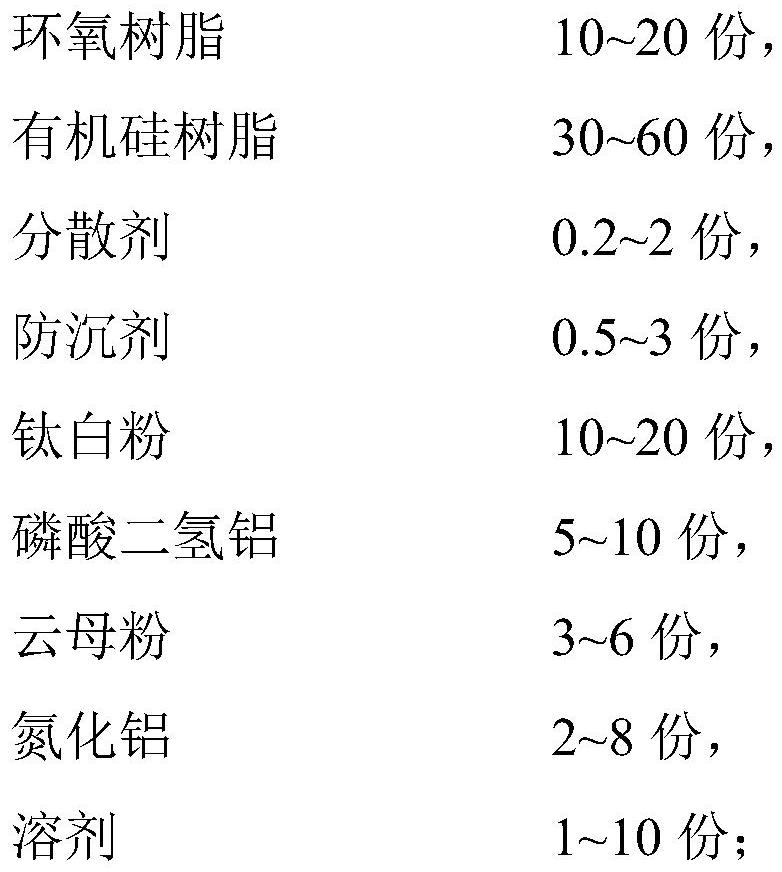

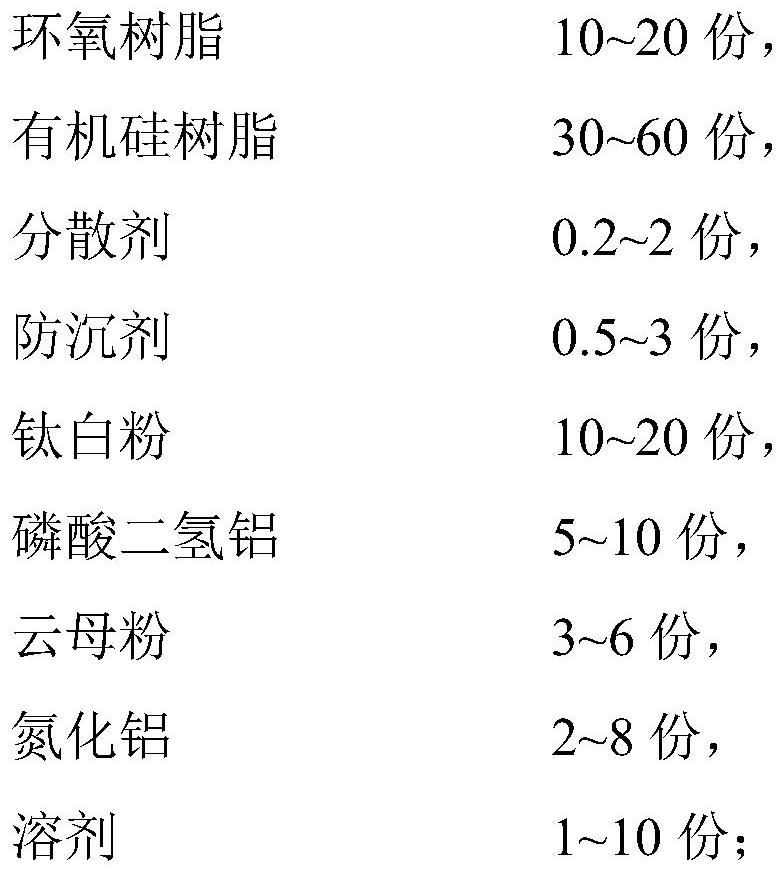

[0035] A method for preparing a low temperature reaction type high temperature resistant coating, comprising the following steps:

[0036] (1) Weigh 10 parts by weight of epoxy resin E51, 50 parts of silicone resin, 2 parts of dispersant, 3 parts of anti-settling agent, 15 parts of titanium dioxide, 10 parts of aluminum dihydrogen phosphate, 6 parts of mica powder, nitrogen 3 parts of aluminum chloride, 1 part of xylene;

[0037] (2) Put xylene into the reaction kettle, raise the temperature to 125-135°C, start to add epoxy resin E51 and silicone resin dropwise, and complete the dropwise addition within 4-5 hours, and the stirring speed is 300-500r / min;

[0038] (3) Continue to add dispersant, anti-sedimentation agent, titanium dioxide, aluminum dihydrogen phosphate, mica powder and aluminum nitride, increase the speed to 800-1000r / min, stir for 2-3 hours, and obtain component A;

[0039] (4) Weigh 40-50 parts of organic amine and 40-50 parts of solvent to obtain component B ...

Embodiment 2

[0042] A method for preparing a low temperature reaction type high temperature resistant coating, comprising the following steps:

[0043] (1) Weigh 20 parts by weight of epoxy resin E51, 40 parts of silicone resin, 2 parts of dispersant, 3 parts of anti-settling agent, 20 parts of titanium dioxide, 5 parts of aluminum dihydrogen phosphate, 5 parts of mica powder, nitrogen 4 parts of aluminum chloride, 1 part of xylene;

[0044] (2) Put xylene into the reaction kettle, raise the temperature to 125-135°C, start to add epoxy resin E51 and silicone resin dropwise, and complete the dropwise addition within 4-5 hours, and the stirring speed is 300-500r / min;

[0045] (3) Continue to add dispersant, anti-sedimentation agent, titanium dioxide, aluminum dihydrogen phosphate, mica powder and aluminum nitride, increase the speed to 800-1000r / min, stir for 2-3 hours, and obtain component A;

[0046](4) Weigh 50 parts of cardanol-modified amine WSCM-1103 by weight, and 50 parts of n-butan...

Embodiment 3

[0049] A method for preparing a low temperature reaction type high temperature resistant coating, comprising the following steps:

[0050] (1) Weigh 15 parts by weight of epoxy resin E51, 60 parts of silicone resin, 0.2 parts of dispersant, 0.5 parts of anti-settling agent, 10 parts of titanium dioxide, 8 parts of aluminum dihydrogen phosphate, 3 parts of mica powder, nitrogen 8 parts of aluminum chloride, 10 parts of xylene;

[0051] (2) Put xylene into the reaction kettle, raise the temperature to 125-135°C, start to add epoxy resin E51 and silicone resin dropwise, and complete the dropwise addition within 4-5 hours, and the stirring speed is 300-500r / min;

[0052] (3) Continue to add dispersant, anti-sedimentation agent, titanium dioxide, aluminum dihydrogen phosphate, mica powder and aluminum nitride, increase the speed to 800-1000r / min, stir for 2-3 hours, and obtain component A;

[0053] (4) Weigh 50 parts of cardanol-modified amine WSCM-1103 by weight, and 50 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com