Preparation method and application of sulfur-doped g-C3N4/alpha-ZrP-carbonized ZIF-8 positive electrode material

A technology of ZIF-8 and positive electrode materials, applied in the direction of positive electrodes, battery electrodes, electrochemical generators, etc., can solve the problems of large volume expansion, low actual capacity, long-chain polysulfide shuttle effect, etc., to promote transformation, Improvement of low capacity, improvement of coulombic efficiency and lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

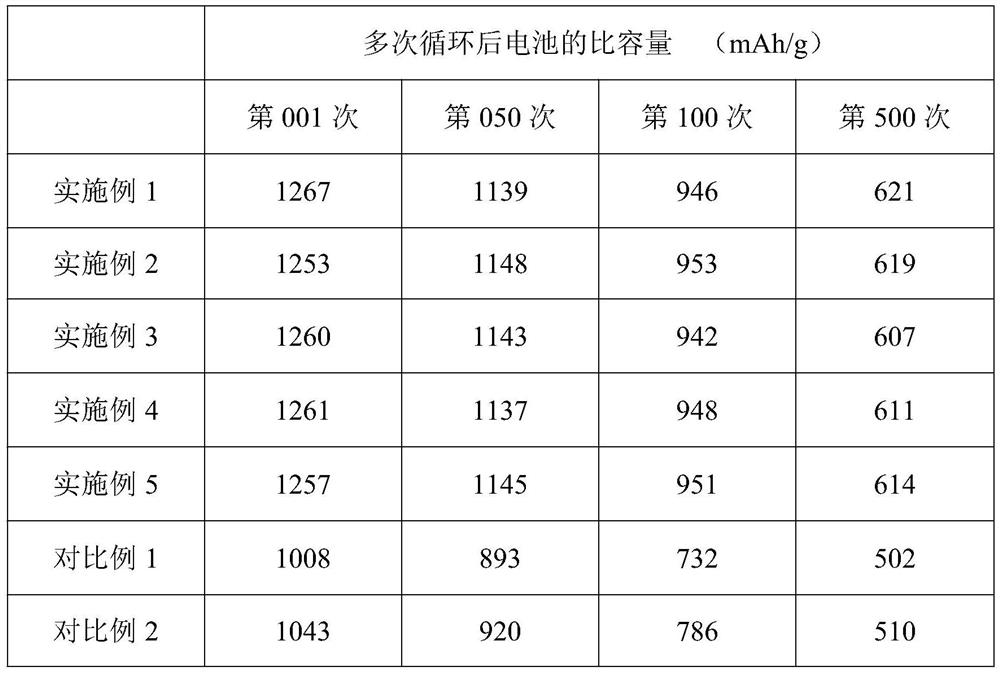

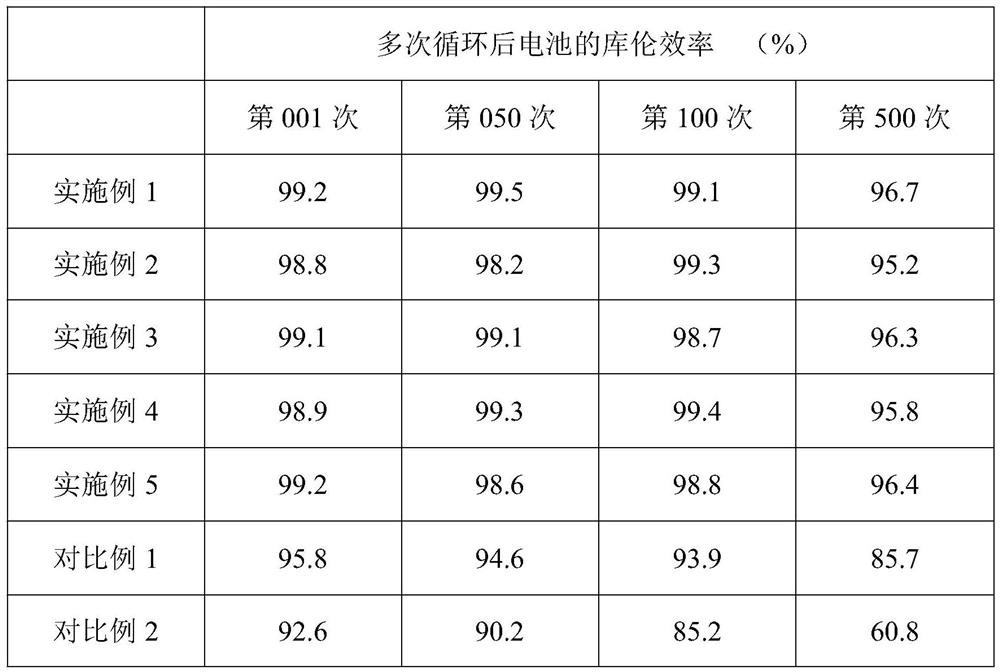

Embodiment 1

[0021] Step 1: Add 1.68g of melamine, 12g of urea and 4g of SBA-15 molecular sieve into 50ml of deionized water, stir in a water bath at 60°C for 60min, then dry and grind in a vacuum oven at 70°C, then mix the ground The powder was placed in a tube furnace at N 2 Under the protection of the atmosphere, the temperature was raised to 560°C at a rate of 2°C / min, calcined for 4h, and after cooling to room temperature, the sample was ground again and soaked in a mixed solution of 44.5ml of 5% hydrofluoric acid and 5.5ml of ethanol for 24h. The samples were then lyophilized to obtain mesoporous g-C 3 N 4 powder.

[0022] Step 2: Dissolve 2.74g of zinc nitrate and 6.18g of 2-methylimidazole in 40mL of methanol respectively, and then add the two solutions simultaneously to the solution containing 12.3g of mesoporous g-C 3 N 4 In 50ml methanol of the powder, the mixture was sonicated at room temperature for 4h and then sealed and aged for 30h, then the solution was centrifuged and...

Embodiment 2

[0026] Step 1: Add 2.52g of melamine, 18g of urea and 4.5g of SBA-15 molecular sieve into 50ml of deionized water, stir in a water bath at 70°C for 40min, then dry and grind in a vacuum oven at 80°C, and then put the ground The mixed powders were placed in a tube furnace at N 2Under the protection of the atmosphere, the temperature was raised to 560°C at a rate of 2°C / min, calcined for 6h, and after cooling to room temperature, the sample was ground again and soaked in a mixed solution of 46.2ml of 5% hydrofluoric acid and 3.8ml of ethanol for 18h. The samples were then lyophilized to obtain mesoporous g-C 3 N 4 powder.

[0027] Step 2: Dissolve 2.65g of zinc nitrate and 5.8g of 2-methylimidazole in 40mL of methanol respectively, and then add the two solutions simultaneously to the solution containing 16.4g of mesoporous g-C 3 N 4 In 50ml methanol of the powder, the mixture was sonicated at room temperature for 3h and then sealed and aged for 24h, then the solution was cen...

Embodiment 3

[0031] Step 1: Add 2.85g of melamine, 15g of urea and 4.2g of SBA-15 molecular sieve into 50ml of deionized water, stir in a water bath at 68°C for 45min, then dry and grind in a vacuum oven at 75°C, then put the ground The mixed powders were placed in a tube furnace at N 2 Under the protection of the atmosphere, the temperature was raised to 560°C at a rate of 2°C / min, and calcined for 5.5 hours. After cooling to room temperature, the sample was ground again and soaked in 45ml of 5% hydrofluoric acid and 5ml ethanol mixed solution for 20h. After soaking The samples were lyophilized to obtain mesoporous g-C 3 N 4 powder.

[0032] Step 2: 3.21g of zinc nitrate and 7.39g of 2-methylimidazole were dissolved in 40mL of methanol, and then the two solutions were simultaneously added to the solution containing 16.1g of mesoporous g-C 3 N 4 In 50ml of methanol powder, the mixture was sonicated at room temperature for 3.2h, sealed and aged for 28h, then the solution was centrifuged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com