High-conductivity inorganic solid electrolyte slurry and preparation method thereof, diaphragm and lithium battery

A solid electrolyte, high conductivity technology, applied in the direction of electrolyte immobilization/gelation, secondary batteries, circuits, etc., can solve problems such as explosion, poor electrolyte wettability, fire, etc., to avoid potential safety hazards and improve Effects of interface compatibility, fire prevention, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

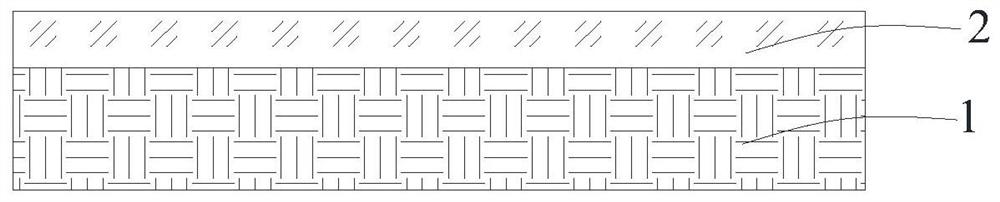

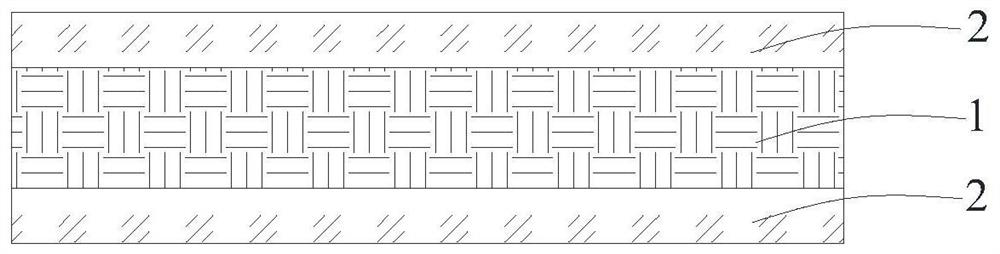

Image

Examples

preparation example Construction

[0019] In order to improve the safety and service life of lithium batteries and avoid potential safety hazards caused by the use of liquid electrolytes, the invention provides a method for preparing a high-conductivity inorganic solid-state electrolyte slurry, which includes the following steps: The electrolyte is organically modified; to prepare a high-conductivity inorganic solid electrolyte solution, add the organically modified high-conductivity inorganic solid electrolyte to the dispersant solution for stirring; high-speed dispersion, that is, to the high-conductivity inorganic solid electrolyte solution Add a thickener solution and perform high-speed dispersion; uniform dispersion, that is, add a binder to the high-conductivity inorganic solid electrolyte solution after high-speed dispersion and make it uniformly dispersed.

[0020] Wherein, the high-conductivity inorganic solid-state electrolyte is LiT 2 (PO 4 ) 3 , wherein T is one or more of Ti, Cr, Zr; the LiT 2 (...

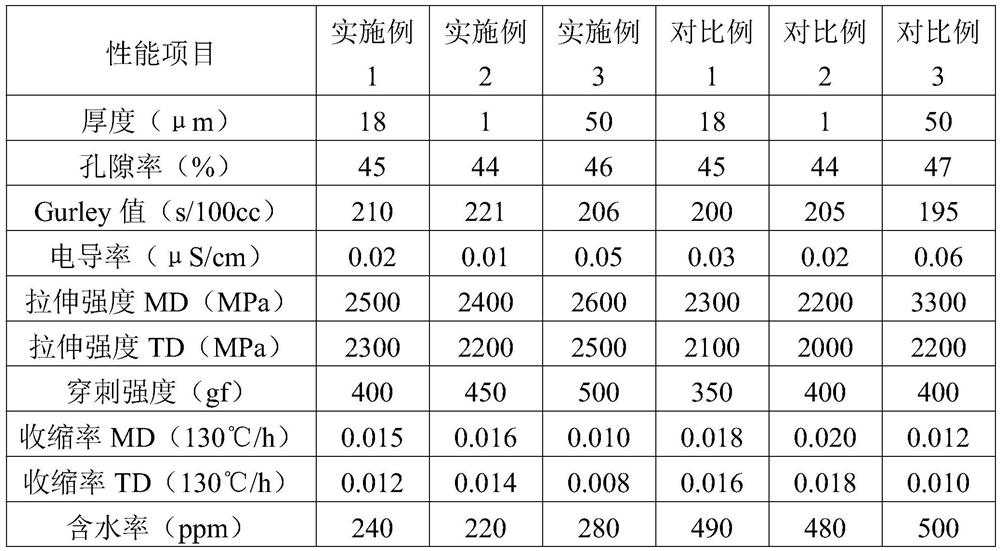

Embodiment 1

[0045] (1) Organic modification of high-conductivity inorganic solid-state electrolytes

[0046] 40kg of LiTi with a particle size D50 of 0.6 μm 2 (PO 4 ) 3 Powder and 0.05kg of PEO were added to 60kg of water to prepare a high-conductivity inorganic solid electrolyte aqueous solution, and 0.2kg of vinyltriethoxysilane was added to the prepared high-conductivity inorganic solid electrolyte aqueous solution, and stirred for 30 minutes.

[0047] (2) Preparation of high conductivity inorganic solid electrolyte solution

[0048] Add 0.24 kg of sodium dodecylbenzenesulfonate to the organically modified high-conductivity inorganic solid-state electrolyte solution, and continue stirring.

[0049] (3) High-speed dispersion

[0050] Add 3.3 kg of sodium carboxymethyl cellulose to the solution in (2), and disperse at a high speed by means of dual planetary agitation.

[0051] (4) uniform dispersion

[0052] Add 1.8 kg of acrylic binder to the solution in (3), and stir for 50 min f...

Embodiment 2

[0060] (1) Organic modification of high-conductivity inorganic solid-state electrolytes

[0061] 40kg of LiCr with a particle size D50 of 0.6 μm 2 (PO 4 ) 3 Powder and 0.05kg of PEO were added to 60kg of water to prepare a high-conductivity inorganic solid electrolyte aqueous solution, and 0.2kg of vinyltriethoxysilane was added to the prepared high-conductivity inorganic solid electrolyte aqueous solution, and stirred for 30 minutes.

[0062] (2) Preparation of high conductivity inorganic solid electrolyte solution

[0063] Add 0.24 kg of sodium dodecylbenzenesulfonate to the organically modified high-conductivity inorganic solid-state electrolyte solution, and continue stirring.

[0064] (3) High-speed dispersion

[0065] Add 1.44 kg of sodium carboxymethylcellulose to the solution in (2), and disperse at high speed by means of dual planetary agitation.

[0066] (4) uniform dispersion

[0067] Add 3.99 kg of acrylic binder to the solution in (3), and stir for 50 min fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size distribution | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com