Light-driven micron sheet array motor system

A micron-chip, light-driven technology, applied in generators/motors, motors with thermal effects, electrical components, etc., can solve problems that limit the application of micro-motor systems, achieve high-efficiency light-to-mechanical energy conversion, enhanced coupling, and good application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

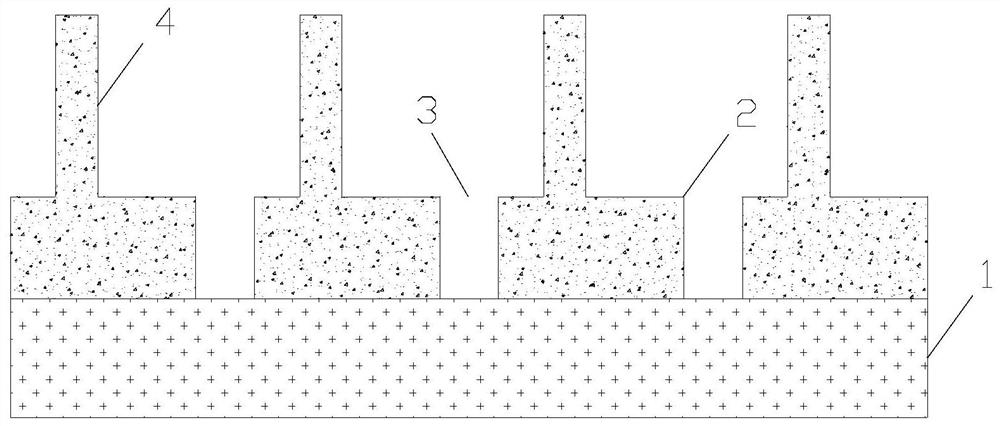

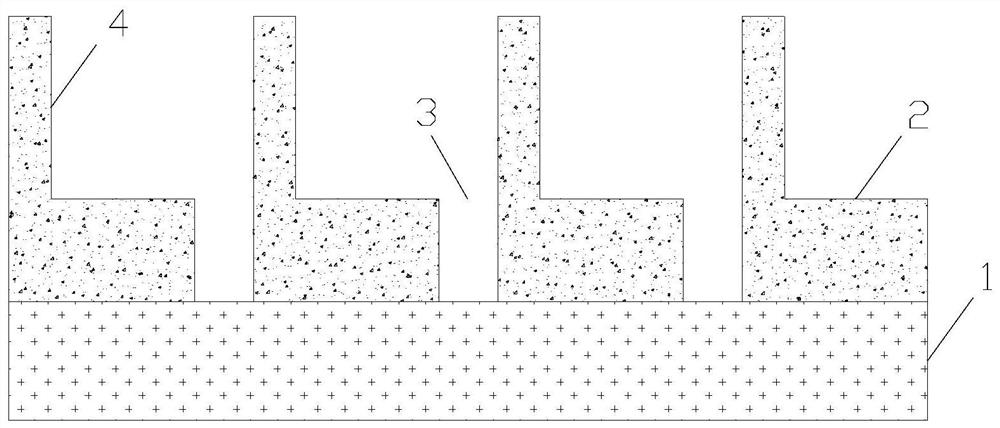

[0020] The invention provides a light-driven microchip array motor system. figure 1 It is a cross-sectional view of the light-driven microsheet array motor system of the present invention, such as figure 1 As shown, the light-driven microchip array motor system includes a substrate 1 , a noble metal layer 2 , a slit 3 , and a noble metal microchip 4 . The noble metal layer 2 is placed on the substrate 1 . The material of the base 1 is a transparent material. Preferably, the material of the substrate 1 is silicon dioxide. The slots 3 are periodically placed in the noble metal layer 2 . The noble metal micro-sheets 4 are vertically placed on the noble metal layer 2 , and the noble metal micro-sheets 4 are periodically and asymmetrically arranged between adjacent gaps 3 . figure 1 The noble metal microflake 4 in is the cross section of the noble metal microflake 4, that is to say, in figure 1 The horizontal direction in is the thickness direction of the noble metal microshee...

Embodiment 2

[0024] On the basis of Embodiment 1, the material of the substrate 1 is a non-transparent material, and the pulsed laser is irradiated from the side of the noble metal microsheet 4 . In this way, the contact area between the light and the micro-nano structure in the present invention is large, and the light can be more coupled into the cavity formed by the noble metal micro-sheet 4. Due to the asymmetric arrangement of the noble metal micro-sheet 4 relative to the slit 3, Stronger and different intensities of surface plasmon polaritons are generated on both sides of the noble metal micro-sheet 4 , thereby generating greater photothermal force on the noble metal micro-sheet 4 , thereby realizing higher-efficiency light-to-mechanical energy conversion.

[0025] Furthermore, the material of the substrate 1 is noble metal. The material of the substrate 1 is the same as that of the noble metal layer 2 or the noble metal microsheet 4 . In this way, the substrate 1 blocks the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com