Wet-type electrostatic precipitation, desulfurization and denitrification integrated device and method

A technology of wet electrostatic precipitator, desulfurization and denitrification, which is applied in the direction of chemical instruments and methods, separation methods, sulfur compounds, etc., can solve the problems of difficulty in applying industrial flue gas treatment, no dust treatment, large floor area, etc., and achieve reuse , small footprint, and the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

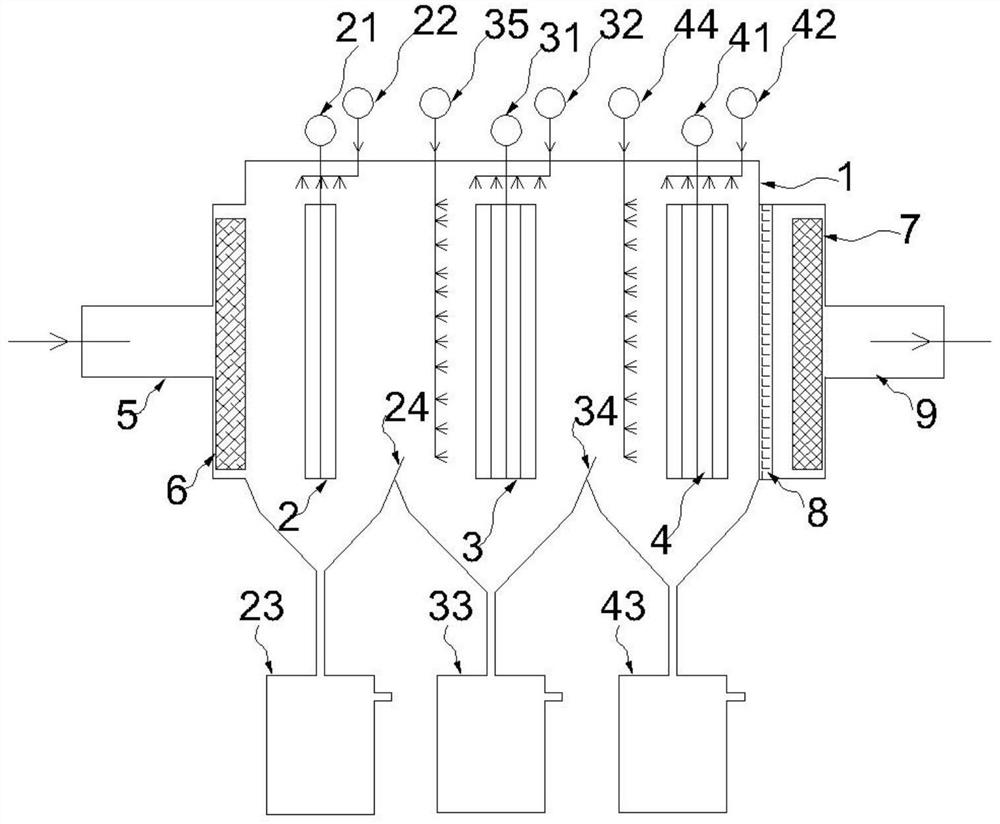

[0099] This embodiment provides a device integrating wet electrostatic precipitator and desulfurization and denitrification, such as figure 1 As shown, the device includes a housing 1 and a reaction chamber formed by a body. Along the flue gas flow direction, the reaction chamber includes an electric dust removal assembly, a desulfurization assembly and a denitrification assembly arranged in sequence; the lower part of the reaction chamber is arranged There are three conical cavities, namely the first conical cavity, the second conical cavity and the third conical cavity, and the three conical cavities are respectively arranged correspondingly to the electrostatic precipitator assembly, the desulfurization assembly and the denitrification assembly.

[0100] The electrostatic precipitator assembly includes a first pole plate arranged in the reaction chamber; the first pole plate 2 is connected with a DC power supply 21; the first pole plate 2 is provided with a first water showe...

Embodiment 2

[0104] This embodiment provides a device integrating wet electrostatic precipitator and desulfurization and denitrification, such as figure 1 As shown, the device includes a housing 1 and a reaction chamber formed by a body. Along the flue gas flow direction, the reaction chamber includes an electric dust removal assembly, a desulfurization assembly and a denitrification assembly arranged in sequence; the lower part of the reaction chamber is arranged There are three conical cavities, namely the first conical cavity, the second conical cavity and the third conical cavity, and the three conical cavities are respectively arranged correspondingly to the electrostatic precipitator assembly, the desulfurization assembly and the denitrification assembly.

[0105] The electrostatic precipitator assembly includes a first pole plate arranged in the reaction chamber; the first pole plate 2 is connected with a DC power supply 21; the first pole plate 2 is provided with a first water showe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com