Catalyst for isomerization of lubricating oil and preparation method thereof

A catalyst and isomerization technology, applied in catalyst activation/preparation, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of lack of catalyst preparation methods, achieve good hydrogenation ring-opening performance, and reduce n-paraffin content , the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

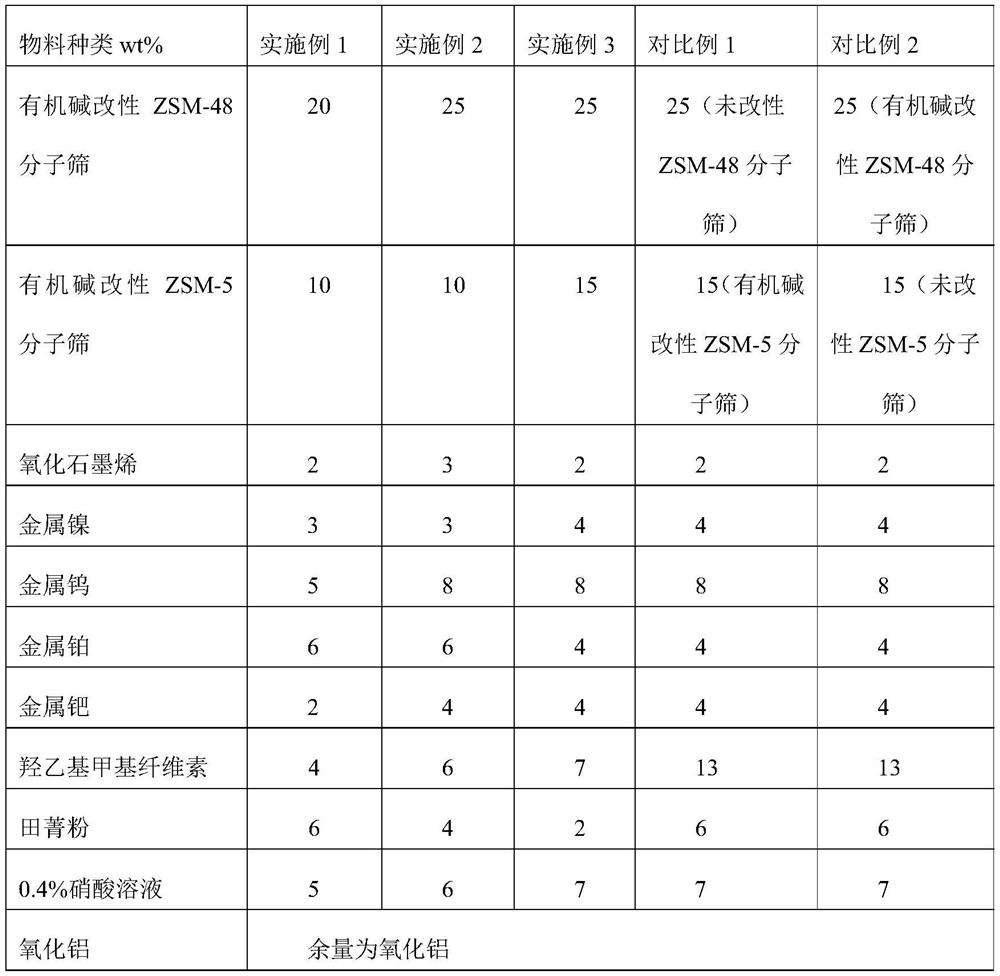

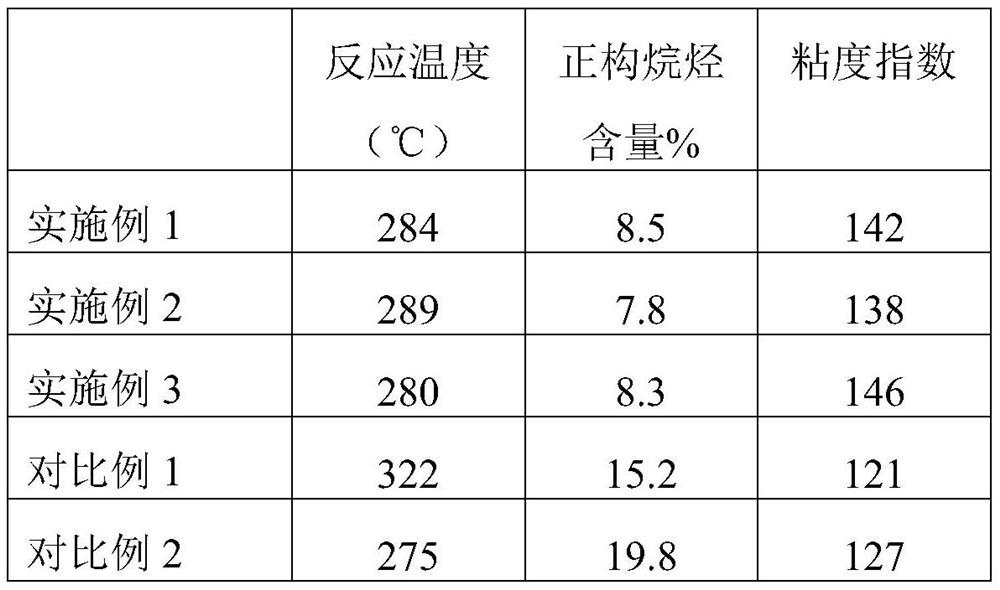

[0026] The dosage of each raw material is shown in Table 1.

[0027] (1) Mix alumina powder, organic base-modified ZSM-48 molecular sieve powder, organic base-modified ZSM-5 molecular sieve powder, and graphene oxide powder evenly, then add hydroxyethyl methylcellulose, squash powder, 0.4 % nitric acid solution, fully rolled and shaped, then roasted at 550°C for 14 hours to obtain a catalyst carrier;

[0028] (2) impregnating the catalyst carrier obtained in step (1) with an equal volume of a solution containing nickel and palladium for 4 hours, then drying at 100° C. for 16 hours, and roasting at 650° C. for 14 hours to obtain a catalyst intermediate;

[0029] (3) impregnating the catalyst intermediate obtained in step (2) with equal volumes of a solution containing platinum and tungsten for 4 hours, then drying at 100° C. for 16 hours, and calcining at 650° C. for 14 hours.

[0030] Preparation of organic base-modified ZSM-48 molecular sieve: join ZSM-48 molecular sieve in ...

Embodiment 2

[0033] The dosage of each raw material is shown in Table 1.

[0034] (1) Mix alumina powder, organic base-modified ZSM-48 molecular sieve powder, organic base-modified ZSM-5 molecular sieve powder, and graphene oxide powder evenly, then add hydroxyethyl methylcellulose, squash powder, 0.4 % nitric acid solution, fully rolled and compacted, then calcined at 650°C for 10 hours to obtain a catalyst carrier;

[0035] (2) impregnating the catalyst carrier obtained in step (1) with an equal volume of a solution containing nickel and platinum for 6 hours, then drying at 120° C. for 12 hours, and roasting at 750° C. for 10 hours to obtain a catalyst intermediate;

[0036] (3) impregnating the catalyst intermediate obtained in step (2) with equal volumes of a solution containing palladium and tungsten for 6 hours, then drying at 120° C. for 12 hours, and calcining at 750° C. for 10 hours.

[0037] The preparation of organic base modified ZSM-48 molecular sieve: ZSM-48 molecular sieve ...

Embodiment 3

[0040] The dosage of each raw material is shown in Table 1.

[0041] (1) Mix alumina powder, organic base-modified ZSM-48 molecular sieve powder, organic base-modified ZSM-5 molecular sieve powder, and graphene oxide powder evenly, then add hydroxyethyl methylcellulose, squash powder, 0.4 % nitric acid solution, fully rolled and shaped, then roasted at 600°C for 12 hours to obtain a catalyst carrier;

[0042] (2) impregnating the catalyst carrier obtained in step (1) with an equal volume of a solution containing palladium and tungsten for 5 hours, then drying at 110° C. for 14 hours, and roasting at 700° C. for 12 hours to obtain a catalyst intermediate;

[0043] (3) impregnating the catalyst intermediate obtained in step (2) with an equal volume of a solution containing nickel and platinum for 5 hours, then drying at 110° C. for 14 hours, and calcining at 700° C. for 12 hours to obtain final product.

[0044]The preparation of organic base modified ZSM-48 molecular sieve: ZS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com