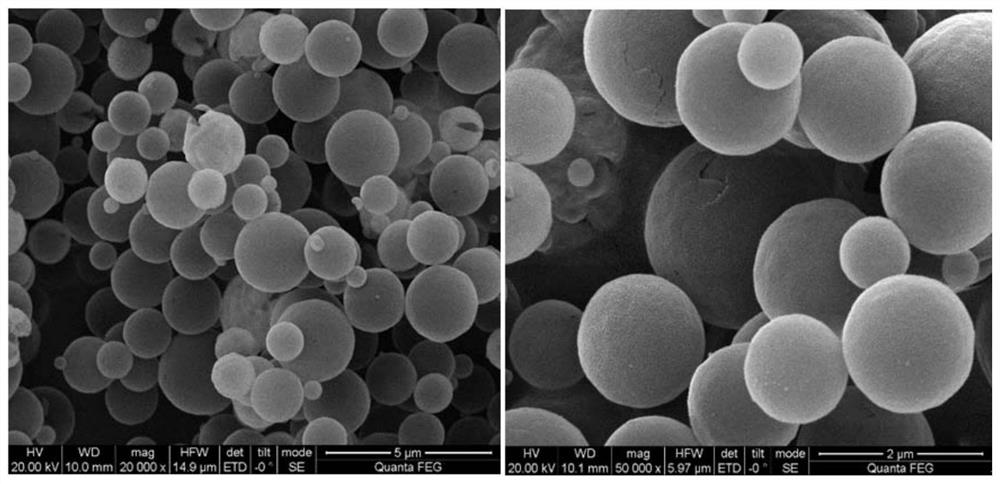

Method for synthesizing ultrathin hollow sphere micron zinc aluminate in one step by flame synthesis method

A flame synthesis, hollow sphere technology, applied in chemical instruments and methods, zinc compounds, inorganic chemistry, etc., can solve the problems of long synthesis time period, complicated operation steps, low product purity, etc. Simple steps and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

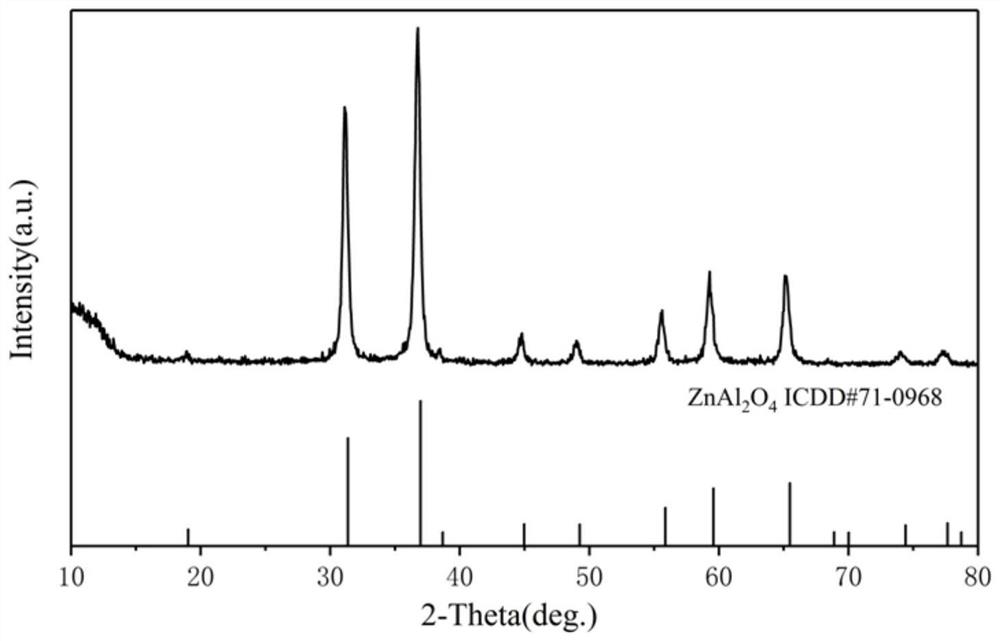

Embodiment 1

[0033] Step 1, Zn(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O was dissolved in 50 mL of water at a molar ratio of 0.75:2, and magnetically stirred at room temperature for 15 min to ensure that the two precursors were fully dissolved and mixed, and then the solution was poured into the atomization device.

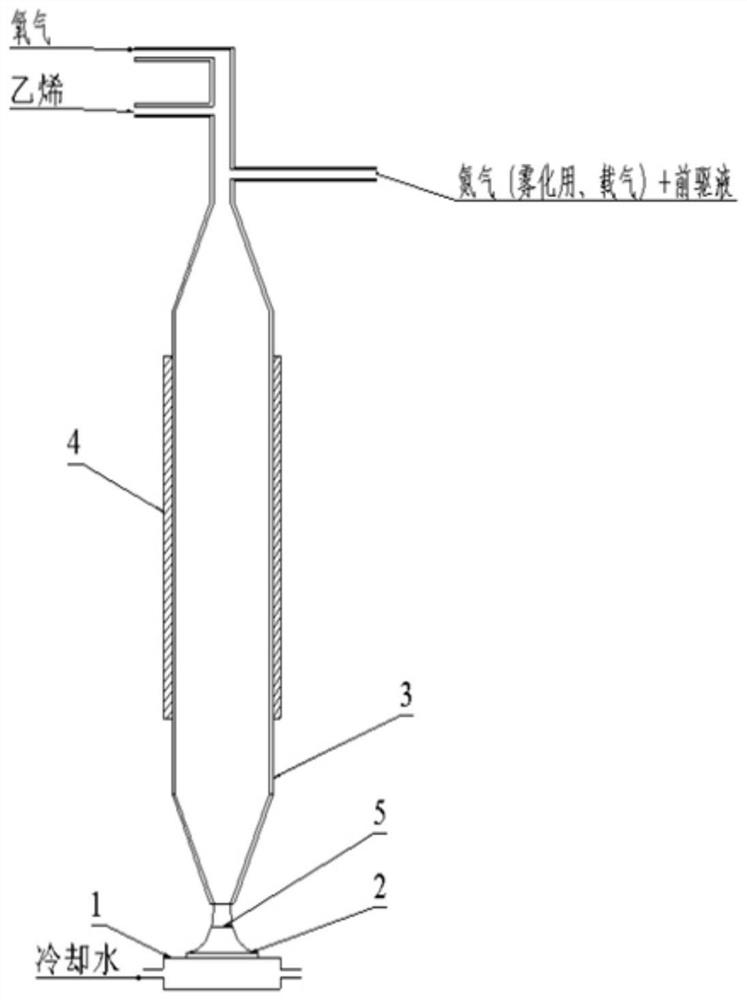

[0034] Step 2, turn on the cooling water pump to keep the cooling substrate at a low temperature, then preheat the burner and the heating belt on the precursor pipeline to heat up to 130°C and 90°C respectively, and then inject nitrogen gas at 10.72SLPM.

[0035] Step 3: Introduce oxygen, ethylene, and nitrogen as a carrier gas successively. The flow rates are 3.8SLPM, 0.72SLPM, and 10.72SLPM respectively. After 10s, ignite the gas at the nozzle of the burner with an ignition gun. After a slight adjustment, the plane flame is within 3 minutes If they are all stable, the nitrogen used for atomization can be passed through. First, slowly increase the nitrogen used for atomiza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com