Preparation method of low-methoxy hawthorn pectin

A technology of low methoxyl group and hawthorn fruit, applied in the field of food deep processing, can solve the problem of not clearly and accurately stating the characteristics of pectin products in the preparation technology of pectin products, and achieves significant social and economic benefits, high purity, and good emulsification. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

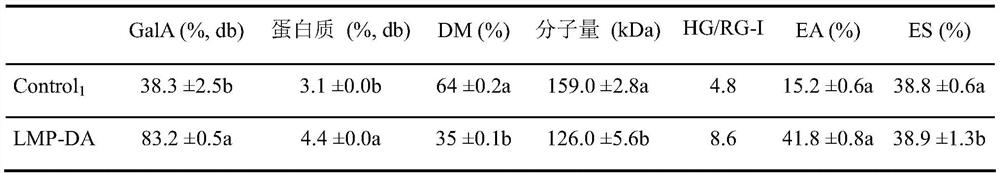

Embodiment 1

[0030] The present embodiment chooses Dajinxing (DA), the main product of Shandong area hawthorn variety, as the test raw material, and the specific implementation steps are as follows:

[0031] 1. Preparation of hawthorn powder

[0032] Fresh hawthorn fruits are destemmed and seeded, cut into thin slices with a thickness of 1mm, and dried with hot air at 40°C until the water content is 10%. Dried hawthorn slices are pulverized, passed through a 40-mesh sieve, and the under-sieve is the prepared hawthorn powder.

[0033] 2. Extraction and separation of hawthorn pectin

[0034] The hawthorn powder 10g prepared in step 1) and 200mL of 95% ethanol were mixed and washed continuously for 1h, centrifuged at 5000r / min for 10min, the supernatant was discarded, and the precipitate was repeatedly washed with 200mL of 95% ethanol (to remove non- cell wall components). Add acetone to the precipitate after washing with ethanol, the mass volume ratio of the precipitate and acetone is 1:1...

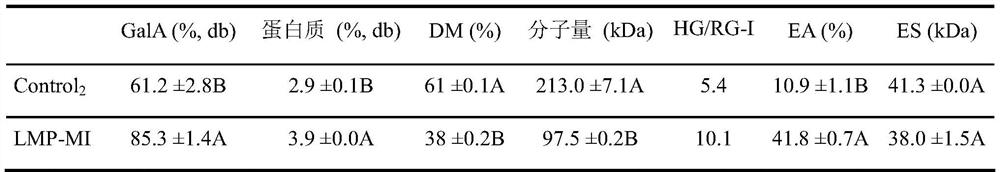

Embodiment 2

[0043] The present embodiment selects Shandong area main product hawthorn variety-cotton ball (MI) as test raw material, and concrete implementation steps are as follows:

[0044] 1. Preparation of hawthorn powder

[0045] Fresh hawthorn fruit is destemmed and seeded, cut into thin slices with a thickness of 1mm, and dried with hot air at 40°C until the moisture content is 8.9%. Dried hawthorn slices are pulverized, passed through a 40-mesh sieve, and the under-sieve is the prepared hawthorn powder.

[0046] 2. Extraction and separation of hawthorn pectin

[0047] Mix 20 g of the hawthorn powder prepared in step 1) with 200 mL of 95% ethanol, continue stirring and washing for 2 h, centrifuge at 5000 r / min for 10 min, discard the supernatant, and repeat washing with ethanol of the same concentration (95%) and volume (200 mL) Precipitate to remove non-cell wall components. Add acetone to the precipitate washed with ethanol, the mass volume ratio of the precipitate to acetone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com