Ternary positive electrode material and preparation method and application thereof

A positive electrode material, three-dimensional technology, applied in the field of ternary positive electrode materials and its preparation, can solve the problems of changing cycle performance, spherical nickel-cobalt lithium manganese oxide with high packing density, and poor rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

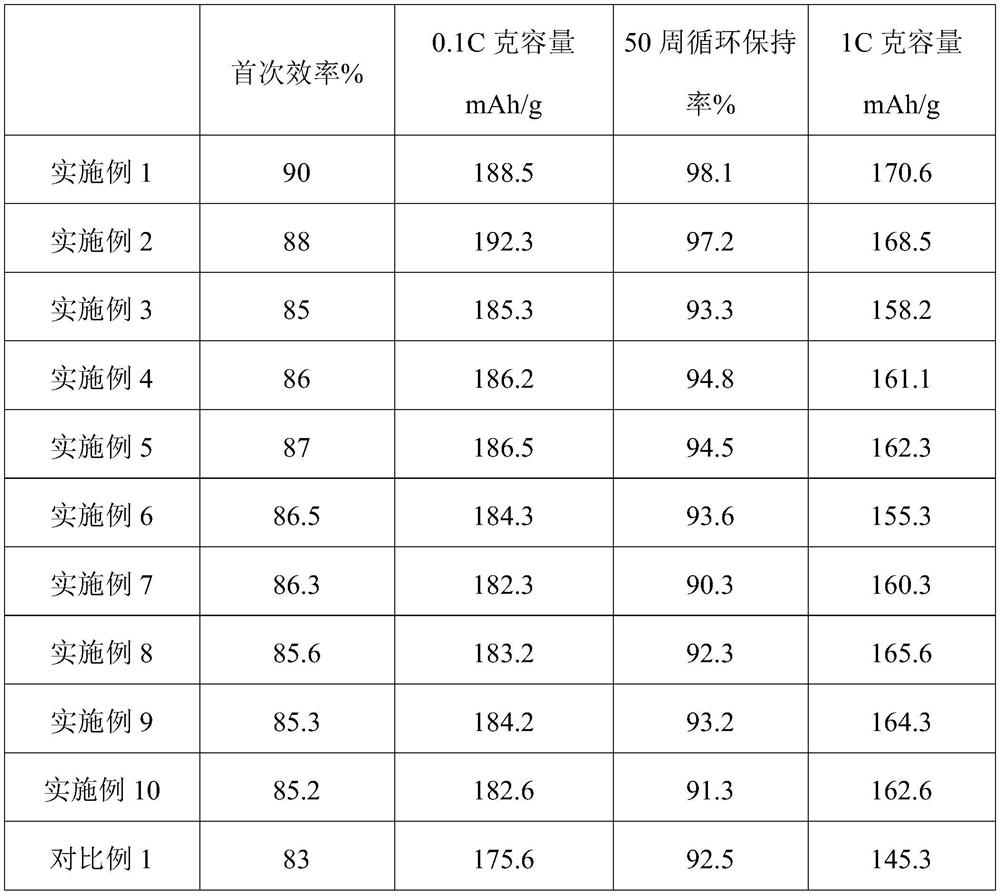

Examples

Embodiment 1

[0072] This embodiment provides a ternary positive electrode material, the specific preparation method is as follows:

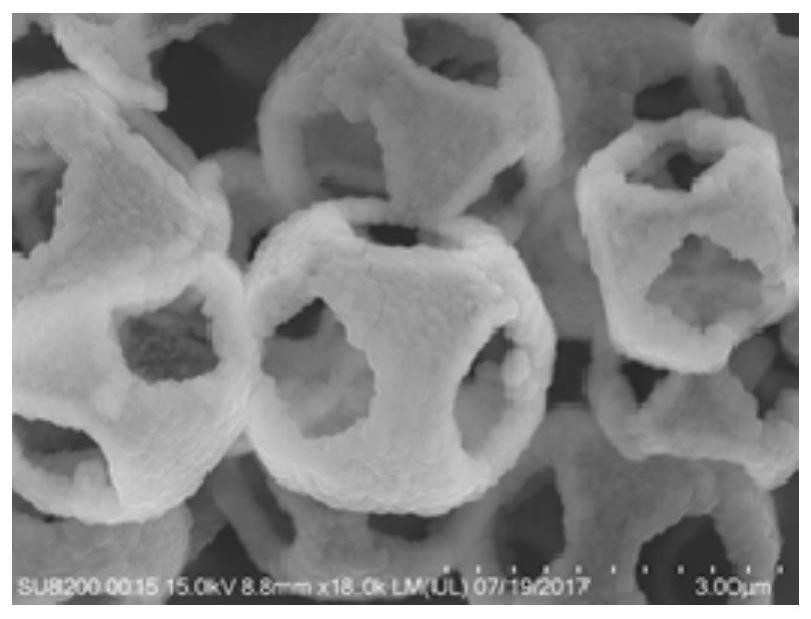

[0073] (1) preparation of nickel chloride, cobalt chloride, manganese chloride mol ratio is 6:1:2, concentration is the metal salt solution I of 0.2mol / L, preparation potassium ferricyanide and sodium citrate mass ratio 10:1 , solution II with a concentration of 0.2mol / L, pour solution I into solution II at a constant speed, stir magnetically at 400rpm for 5 minutes, then seal it in a stainless steel reactor and then put it in a blast drying oven, and conduct a hydrothermal reaction at 160°C After 16 hours, the precursor powder material of the three-dimensional metal-organic framework was obtained after suction filtration, washing and drying. The scanning electron microscope image of the precursor material is as follows: figure 1 shown;

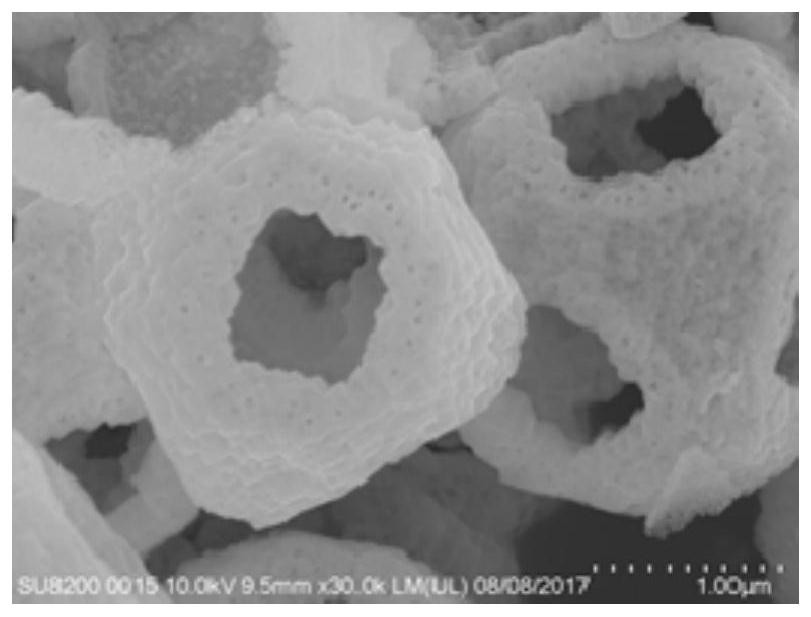

[0074] (2) The precursor powder material of the three-dimensional metal-organic framework described in step (1) was pre-f...

Embodiment 2

[0078] This embodiment provides a ternary positive electrode material, the specific preparation method is as follows:

[0079] (1) preparation of nickel chloride, cobalt chloride, manganese chloride mol ratio is 7:1:2, concentration is the metal salt solution I of 0.5mol / L, preparation potassium cobalt cyanide and sodium citrate mass ratio 6:1 , solution II with a concentration of 0.6mol / L, pour solution I into solution II at a constant speed, stir magnetically at 500rpm for 4min, then seal it in a stainless steel reactor and then place it in a blast drying oven, and conduct a hydrothermal reaction at 170°C After 15 hours, the precursor powder material of the three-dimensional metal-organic framework was obtained after suction filtration, washing and drying;

[0080] (2) The precursor powder material of the three-dimensional metal-organic framework described in step (1) was pre-fired in a box furnace at a heating rate of 1°C / min at 500°C for 10h, and then naturally cooled to o...

Embodiment 3

[0084] The only difference between this embodiment and embodiment 1 is that the temperature of the hydrothermal reaction is 100° C., and other conditions and parameters are exactly the same as those of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com