Laparoscope umbrella-shaped anastomat

A laparoscopy and stapler technology, applied in the field of staplers, can solve the problems of unfavorable patient health, poor antibacterial performance, reduced surgical fluency and ornamental value, etc., and achieve the effect of facilitating rehabilitation, improving antibacterial effect, and preventing bacterial infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

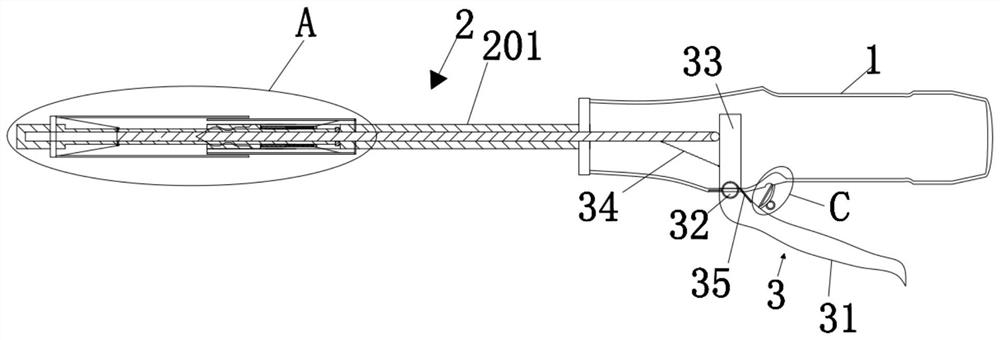

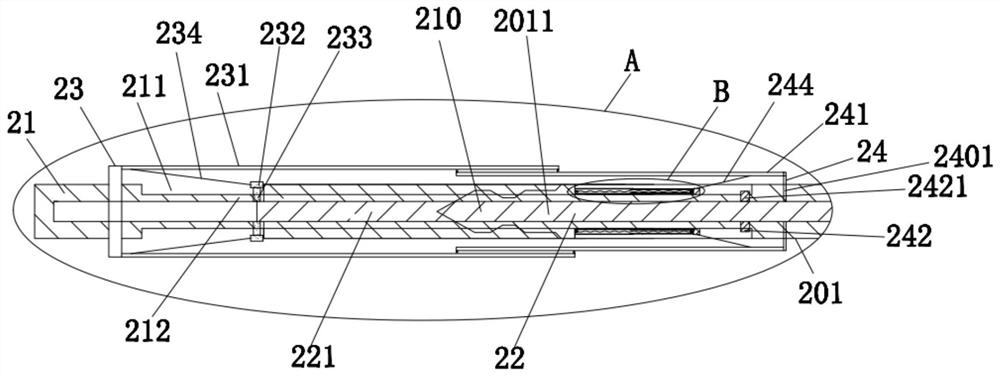

[0057] Such as figure 1 , figure 2 , image 3 , Figure 8 , Figure 9 and Figure 10 As shown, the laparoscopic umbrella stapler provided by the present invention includes a handle 1, a main body 2 is provided on the left side of the handle 1, and a driving structure 3 is provided at the bottom of the handle 1;

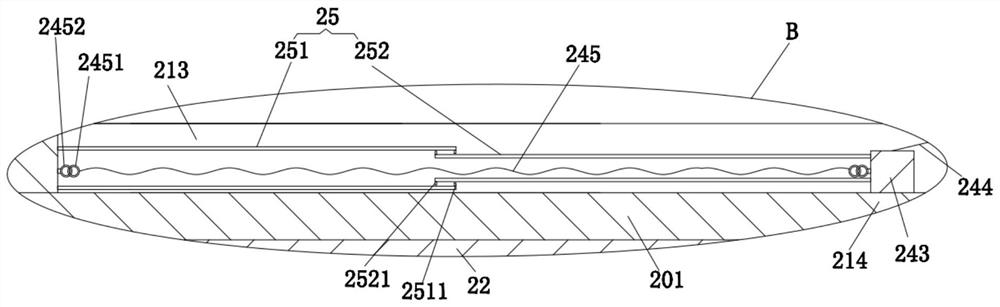

[0058] The main body 2 includes a round tube 201, a spring tube 21, an abutment seat 231 and a body 241. The inside of the round tube 201 and the spring tube 21 are respectively movably inserted with a first nail drill rod 22 and a second nail drill rod 221, and the spring tube The outer wall of 21 is provided with a first annular groove 211, and the outer wall of the circular tube 201 on the right side of the first annular groove 211 is provided with a second annular groove 213, and the outer side of the left end of the spring tube 21 is welded with a first annular groove 23. The center of circle of 231 is movably connected with the outer wall of the first circ...

Embodiment 2

[0080] The difference from Example 1 is that the outer wall of the spring tube 21 is provided with an antibacterial layer, and the antibacterial layer is prepared by the following method:

[0081] Take the following raw materials and weigh them by weight: 6 parts of butyl acrylate, 5 parts of methyl methacrylate, 3 parts of silicone-modified acrylic acid, 4 parts of styrene-acrylic emulsion, 7 parts of acrylate emulsion, 3 parts of polyether polyol, 2 parts of epoxy resin, 10 parts of silicone defoamer, 5 parts of bentonite binder, 90 parts of deionized water;

[0082] S1, material preparation: first weigh the above-mentioned raw materials;

[0083] S2. Preliminary mixing: first add deionized water into the digital constant temperature magnetic stirrer, then pour butyl acrylate, methyl methacrylate, silicone modified acrylic acid in sequence, the stirrer speed is 30r / min, and the temperature is at Stir for 10 minutes at 50°C;

[0084] S3. Stand still: stop the digital displa...

Embodiment 3

[0091] The difference from Example 2 is the preparation of the antibacterial layer, and its specific preparation method is as follows:

[0092] Take the following raw materials and weigh them by weight: 8 parts of butyl acrylate, 7 parts of methyl methacrylate, 7 parts of silicone-modified acrylic acid, 8 parts of styrene-acrylic emulsion, 11 parts of acrylate emulsion, 9 parts of polyether polyol, 6 parts of epoxy resin, 12 parts of silicone defoamer, 9 parts of bentonite binder, 110 parts of deionized water;

[0093] S1, material preparation: first weigh the above-mentioned raw materials;

[0094] S2. Preliminary mixing: first add deionized water into the digital constant temperature magnetic stirrer, then pour butyl acrylate, methyl methacrylate, silicone modified acrylic acid in sequence, the stirrer speed is 30r / min, and the temperature is at Stir for 10 minutes at 50°C;

[0095] S3. Stand still: stop the digital display constant temperature magnetic stirrer, keep the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com