Pt-containing catalyst suitable for gasoline vehicle tail gas purification, and preparation method thereof

A tail gas purification and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of Pt replacing Pd catalysts with thermal stability decline, and achieve excellent Effects of anti-aging performance, improvement of catalytic performance, and improvement of thermal aging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

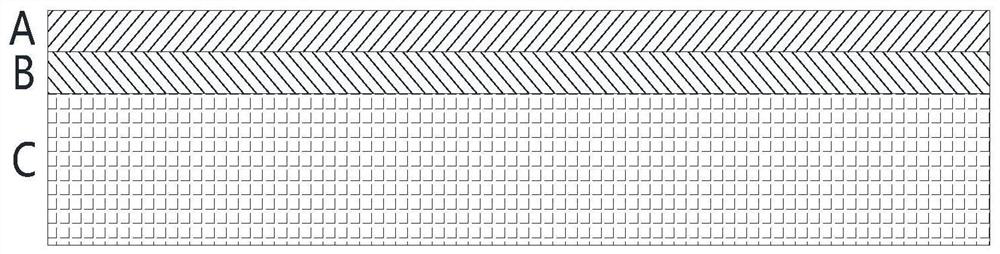

Image

Examples

Embodiment 1

[0031] Undercoat composition:

[0032] The underlying coating is a Pt-Pd layer with a Pt content of 50g / ft 3 , Pd content is 50g / ft 3. impregnated in the first cerium-zirconium composite oxide (40wt% CeO 2 , 55wt% ZrO 2 , 5wt% La 2 o 3 ) of Pt is 40g / ft 3 , Pd is 10g / ft 3 ,CeO 2 The content is 5% of the first cerium-zirconium composite oxide. 10 g / ft of Pt impregnated in lanthanum modified alumina (1% lanthanum content) 3 ,Pd is 40g / ft 3 , the BaO content is 5% of lanthanum-modified alumina, the first cerium-zirconium composite oxide in the bottom coating is 50g / L, the lanthanum-modified alumina is 50g / L, and the binder aluminum sol is 3g / L. The coating amount was 103 g / L.

[0033] Top coat composition:

[0034] Top coating Rh layer, Rh content is 10g / ft 3 . Among them, in the second cerium-zirconium composite oxide (10wt% CeO 2 , 85wt% ZrO 2 , 5wt% La 2 o 3 ) impregnated with 7.0gRh and 1% Nd 2 o 3 , Rh 3.0 g / ft impregnated in lanthanum-modified alumina (...

Embodiment 2

[0043] Undercoat composition:

[0044] The underlying coating is a Pt-Pd layer with a Pt content of 20g / ft 3 , Pd content is 20g / ft 3 . impregnated in the first cerium-zirconium composite oxide (40wt% CeO 2 , 55wt% ZrO 2 , 5wt%Pr 6 o 11 ) of Pt is 19g / ft 3 , Pd is 1g / ft 3 ,CeO 2 The content is 5% of the first cerium-zirconium composite oxide, and the first cerium-zirconium composite oxide is 1 g / ft of Pt impregnated in lanthanum-modified alumina (lanthanum content is 5 wt%) 3 ,Pd is 19g / ft 3 , the content of BaO is 10wt% of lanthanum-modified alumina, the first cerium-zirconium composite oxide in the bottom coating is 50g / L, the lanthanum-modified alumina is 50g / L, and the binder aluminum sol is 10g / L. The coating amount was 110 g / L.

[0045] Top coat composition:

[0046] Top coating Rh layer, Rh content is 10g / ft 3 . Among them, in the second cerium-zirconium composite oxide (10wt% CeO 2 , 85wt% ZrO 2 , 5wt% Nd 2 o 3 ) impregnated to 9g / ft 3 Rh and 5% Nd ...

Embodiment 3

[0055] Undercoat composition:

[0056] The underlying coating is a Pt-Pd layer with a Pt content of 150g / ft 3 , Pd content is 50g / ft 3 . Immersed in the first cerium-zirconium composite oxide (40wt% CeO2, 55wt% ZrO2, 5wt% Pr 6 o 11 ) of Pt is 140g / ft 3 , Pd is 10g / ft 3 ,CeO 2 The content is 10% of the first cerium-zirconium composite oxide, the first cerium-zirconium composite oxide is 10 g / ft of Pt impregnated in lanthanum-modified alumina (10% lanthanum content) 3 ,Pd is 40g / ft 3 , the SrO content is 8% of lanthanum-modified alumina, the first cerium-zirconium composite oxide in the bottom coating is 150g / L, the lanthanum-modified alumina is 40g / L, and the binder aluminum sol is 10g / L. The coating amount was 200 g / L.

[0057] Top coat composition:

[0058] Top coating Rh layer, Rh content is 20g / ft 3 . Wherein the second cerium-zirconium composite oxide (10wt% CeO2, 85wt% ZrO2, 5wt% Nd 2 o 3 ) impregnated to 16g / ft 3 Rh and 5% Nd 2 o 3 , Rh impregnated in la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com