High-stability solid-solid composite phase change material and preparation method thereof

A composite phase change material and high stability technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of easy leakage of molten state, low heat storage/release rate, etc., and achieve easy access to raw materials and simple operation , high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The high stability solid-solid composite phase change material described in this example was prepared according to the following formula and steps.

[0046] Step 1, preparation of double-terminal aldehyde group polyethylene glycol aqueous solution:

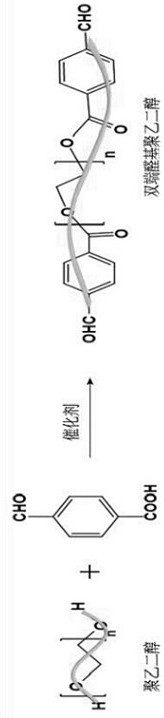

[0047] The preparation mechanism is as figure 1 As shown, the specific operation process is as follows:

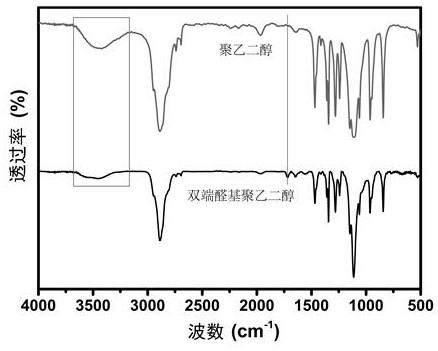

[0048]2.50mmol of polyethylene glycol with a molar mass of 600, 6.00mmol of p-formylbenzoic acid, 7.50mmol of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 7.50mmol of pyridine Dissolved in 250ml of dichloromethane successively, stirred at room temperature for 48 hours, removed the dichloromethane by rotary evaporation, washed 5 times with glacial ether, and vacuum-dried at 25°C for 12 hours to obtain double-terminal aldehyde polyethylene glycol ; Dissolve double-ended aldehyde-based polyethylene glycol into deionized water to make 60wt% double-ended aldehyde-based polyethylene glycol aqueous solutio...

Embodiment 2

[0056] Step 1, preparation of double-terminal aldehyde group polyethylene glycol aqueous solution:

[0057] 2.50mmol of polyethylene glycol with a molar mass of 2000, 7.50mmol p-formylbenzoic acid, 7.50mmol1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 7.50mmol pyridine Dissolved in 250ml of dichloromethane successively, stirred at room temperature for 48 hours, removed the dichloromethane by rotary evaporation, washed 5 times with glacial ether, and vacuum-dried at 25°C for 12 hours to obtain double-terminal aldehyde polyethylene glycol ; Dissolve double-ended aldehyde-based polyethylene glycol into deionized water to make 50wt% double-ended aldehyde-based polyethylene glycol aqueous solution for subsequent use.

[0058] Step 2, prepare chitosan solution:

[0059] Weigh 1.2g of chitosan and dissolve it into a mixed solution containing 99.5ml of deionized water and 0.5ml of acetic acid to prepare a chitosan solution for subsequent use.

[0060] Step 3, addit...

Embodiment 3

[0066] Step 1, preparation of double-terminal aldehyde group polyethylene glycol aqueous solution:

[0067] 2.50mmol of polyethylene glycol with a molar mass of 4000, 10.00mmol p-formylbenzoic acid, 7.50mmol1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 7.50mmol pyridine Dissolved in 250ml of dichloromethane successively, stirred at room temperature for 48 hours, removed the dichloromethane by rotary evaporation, washed 5 times with glacial ether, and vacuum-dried at 25°C for 12 hours to obtain double-terminal aldehyde polyethylene glycol ; Dissolve double-ended aldehyde-based polyethylene glycol into deionized water to make 40wt% double-ended aldehyde-based polyethylene glycol aqueous solution for subsequent use.

[0068] Step 2, prepare chitosan solution:

[0069] Weigh 0.35g of chitosan and dissolve it into a solution containing 99.5ml and 0.5ml of acetic acid to prepare a chitosan solution for subsequent use.

[0070] Step 3, addition of inorganic framew...

PUM

| Property | Measurement | Unit |

|---|---|---|

| latent heat | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com