Preparation method of catalyst for preparing diol by hydrating alkylene oxide and catalyst prepared by preparation method

An alkylene oxide water and catalyst technology, which is applied in the field of catalysts, can solve the problems of high water ratio required and the recyclability needs to be improved, and achieve the effects of high activity, excellent recyclability and excellent recyclability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

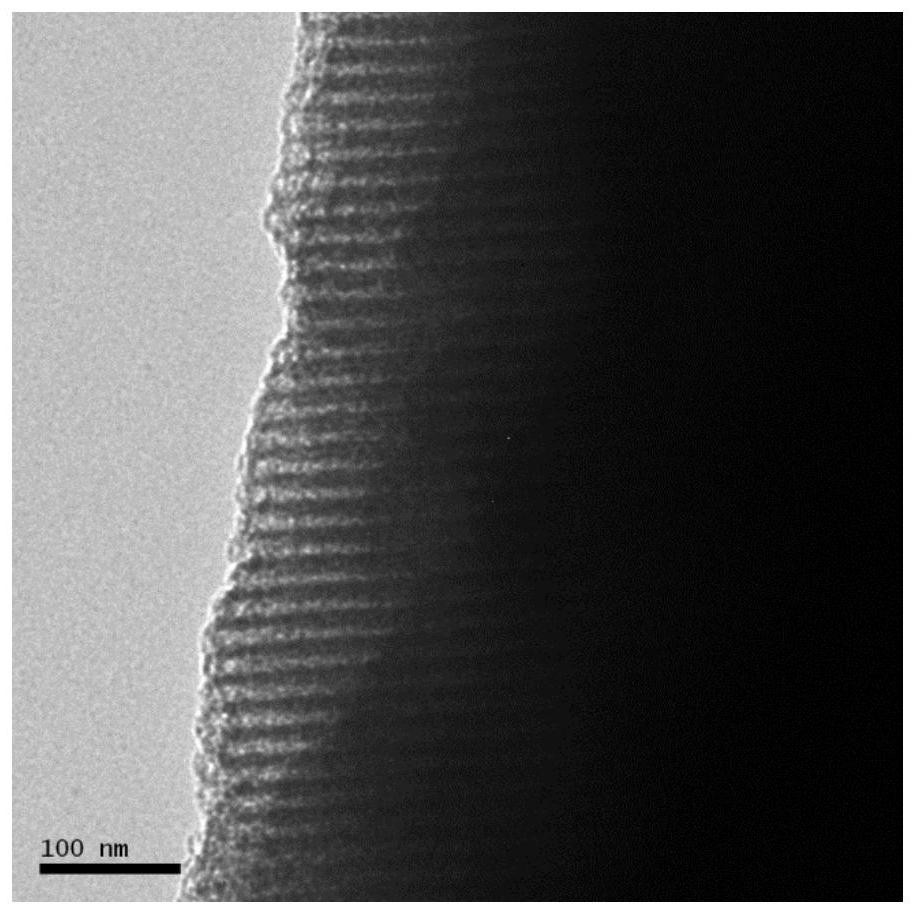

Image

Examples

Embodiment 1

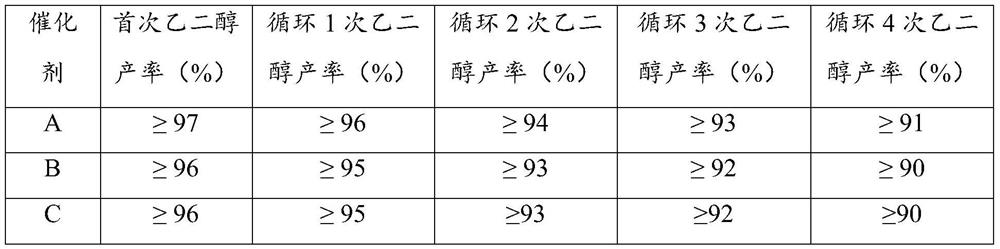

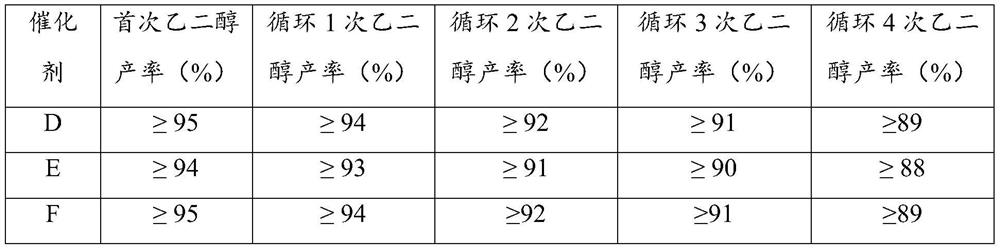

[0028] Weigh 0.50g of F127, 0.6g of mesitylene and 2.5g of KCl and dissolve them in 30mL of 2M HCl aqueous solution at 16°C, stir for 2h; add 2.08g of TEOS, continue to stir at 16°C for 24h, then place in 100 ℃ water heating in oven for 24h. After it was taken out, washed and dried, it was calcined at 550°C for 6 hours to obtain the nanocage matrix material FDU-12. Weigh 0.331g of ferrocene hexafluorophosphoric acid and 0.492g of Co(N,N'-disalicylidene-1,2-cyclohexanediamine), dissolve in a mixed solution of 15mL dichloromethane and 15mL acetonitrile , stirred at room temperature for 12 hours, the solvent was spun off, and the active center Co(N,N'-disalicylidene-1,2-cyclohexanediamine)PF was obtained after fully washing and drying with n-hexane 6 . Weigh 1.0g of FDU-12, put in 6mL containing 110mg Co(N,N'-disalicylidene-1,2-cyclohexanediamine) PF 6 In the dichloromethane solution of 20 ℃ sealed stirring 2h, 20 ℃ open stirring until the solvent evaporated to dryness. Add p...

Embodiment 2

[0030] Weigh 1.0g of SBA-6 and place in 6mL containing 110mg Fe(N,N'-bis(3,5-di-tert-butylsalicylidene)-1,2-cycloethylenediamine)PF 6 In the dichloromethane solution of 20 ℃ sealed stirring 2h, 20 ℃ open stirring until the solvent evaporated to dryness. Add pre-hydrolyzed methyl orthosilicate, stir for 40 minutes, add a mixture of water and methanol with a water volume percentage of 3%, centrifuge after stirring, repeat once, then fully wash with ethanol, and dry to obtain catalyst B.

Embodiment 3

[0032]Weigh 1.0g of SBA-16 and place in 6mL containing 110mg Ga(N,N'-disalicylidene-1,2-cycloethylenediamine) PF 6 In the dichloromethane solution of 20 ℃ sealed stirring 2h, 20 ℃ open stirring until the solvent evaporated to dryness. Add pre-hydrolyzed methyl orthosilicate, stir for 40 minutes, add a mixture of water and methanol with a water volume percentage of 7%, centrifuge after stirring, wash fully with methanol, and dry to obtain catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com