Preparation method of aporphine alkaloids and intermediates thereof

A technology for alkaloids and intermediates of aporphim, applied in the field of preparation of natural products and their intermediates, can solve problems such as increasing the complexity of synthetic strategies, and achieve the effects of simple synthetic strategies, economical reactions, and strong substrate applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

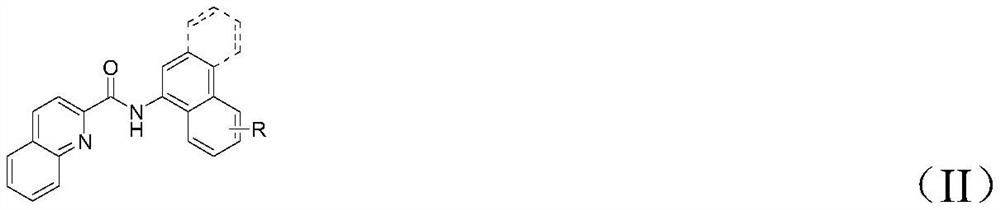

[0039] Dissolve quinoline-2-carboxylic acid (20mmol), naphthalene-1-amine (20mmol, 2.86g) and triethylamine (40mmol, 5.6mL) in CH 2 Cl 2 (40mL), then POCl was added dropwise at 0°C 3 (3.76 mL). The reaction mixture was stirred at 0 °C for 0.5 h. The reaction was then stirred at room temperature for 2 h until the naphthalene-1-amine was consumed. After the reaction was completed, the reaction mixture was cooled to 0 °C, and ice water was slowly added to quench the reaction. Collect the organic phase, then extract the aqueous phase with dichloromethane (3×20 mL), combine the organic phases, wash with saturated NaHCO 3 (2×40mL) aqueous solution, then washed with MgSO 4 dry. The solvent was spin-dried under reduced pressure, and the crude product was recrystallized from dichloromethane / petroleum ether to obtain the target product II-1.

[0040] The reaction formula is as follows:

[0041]

[0042] Product characterization data are as follows:

[0043] N-(Naphthalen-1-yl...

Embodiment 2

[0044] Example 2 Preparation of raw material N-(phenanthren-9-yl)quinoline-2-carboxamide II-2

[0045] The reaction formula is as follows:

[0046]

[0047] step 1:

[0048] To quinoline-2-carboxylic acid (3.46g, 20mmol, 1equiv) and (Boc) 2 To a solution of O (5.68 g, 26 mmol, 1.3 equiv) in 1,4-dioxane (100 mL) was added pyridine (2 mL). Stir for 10 min, add NH in batches 4 HCO 3 (2.06g, 26mmol, 1.3equiv), then stirred at room temperature for 24 hours. After the reaction was complete, the solvent was spin-dried, the residue was dissolved with EtOAc (200 mL), and the organic phase was dissolved with NaHCO 3 (3 x 80 mL) and water (80 mL), dried over anhydrous sodium sulfate, then removed the solvent and dried to give quinoline-2-carboxamide. The structure and characterization data of the product are as follows:

[0049]

[0050]Quinoline-2-carboxamide (CAS no.5382-42-3): 2.96g, 86% yield; white solid; mp=126-128℃; 1 H NMR (400MHz, CDCl 3 )δ8.31(d, J=8.4Hz, 1H), 8....

Embodiment 3

[0055] Embodiment 3 Alkylation reaction

[0056] Under air atmosphere, amide II-1 or II-2 (0.25mmol, 1.0equiv), ethyl bromoacetate (0.5mmol, 84mg), Pd(OAc) 2 (0.025mmol, 6mg), PhCOOK (0.5mmol, 80mg) and 1,2-dichloroethane (2.0mL) were mixed and placed in a 35mL pressure reaction tube with a polytetrafluoroethylene cap. The reaction tube was heated at 90 °C for 12 h. The reaction mixture was cooled to room temperature, diluted with ethyl acetate (5 mL), filtered through celite, concentrated in vacuo, and the residue was purified with a silica gel column (eluent was petroleum ether and ethyl acetate) to obtain the target product III-1 or III -2.

[0057] The structure and characterization data of compound III-1 are as follows:

[0058]

[0059] Ethyl 2-(8-quoinoline-2-carboxamido)naphthalen-1-yl)acetate(III-1): 83mg; Yield: 86%; Column chromatography gave a white solid (eluent: ethyl acetate / petroleum ether =1 / 6, v / v); mp=128-129°C; 1 H NMR (400MHz, CDCl 3 )δ10.87(s,1H)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com