Catalyst composition and preparation method of polylactide

A composition and catalyst technology, applied in the polymer field, can solve the problems of low molecular weight of polylactide, uncontrollable molecular weight, low polymer molecular weight, etc., and achieve the effect of high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

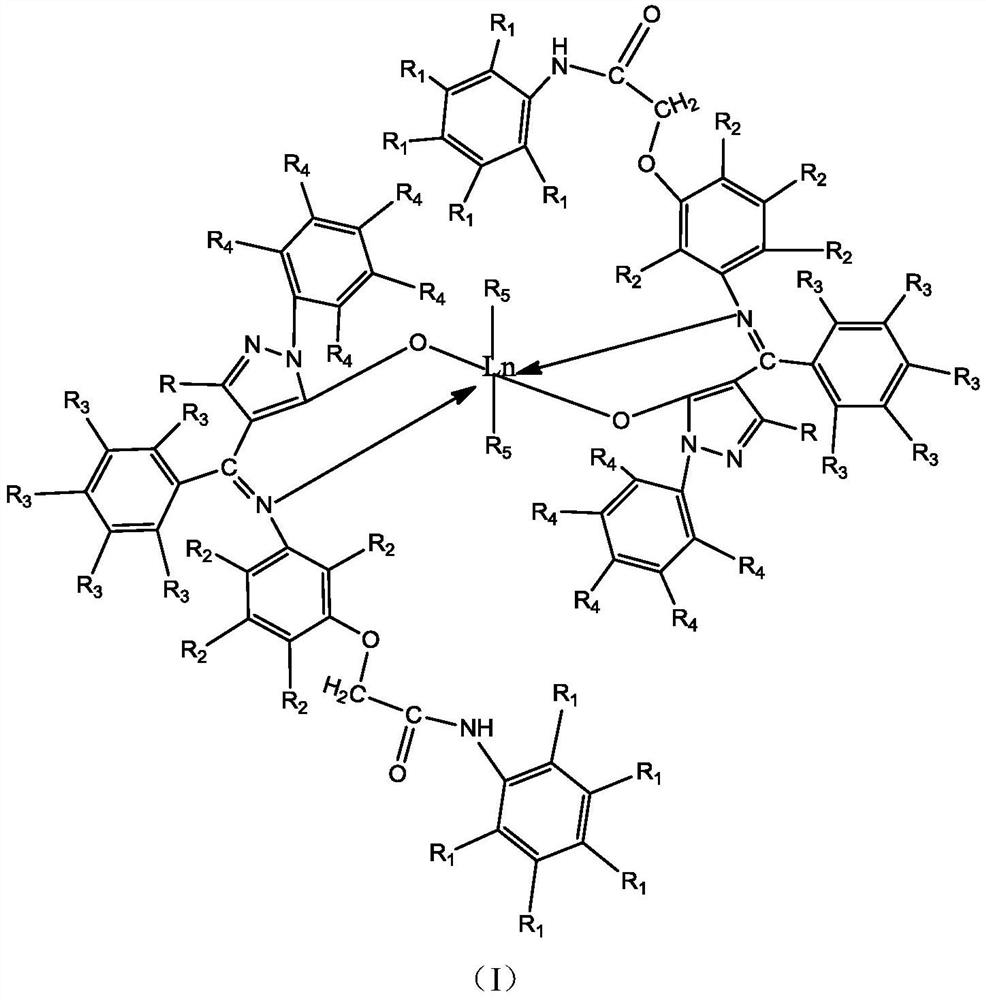

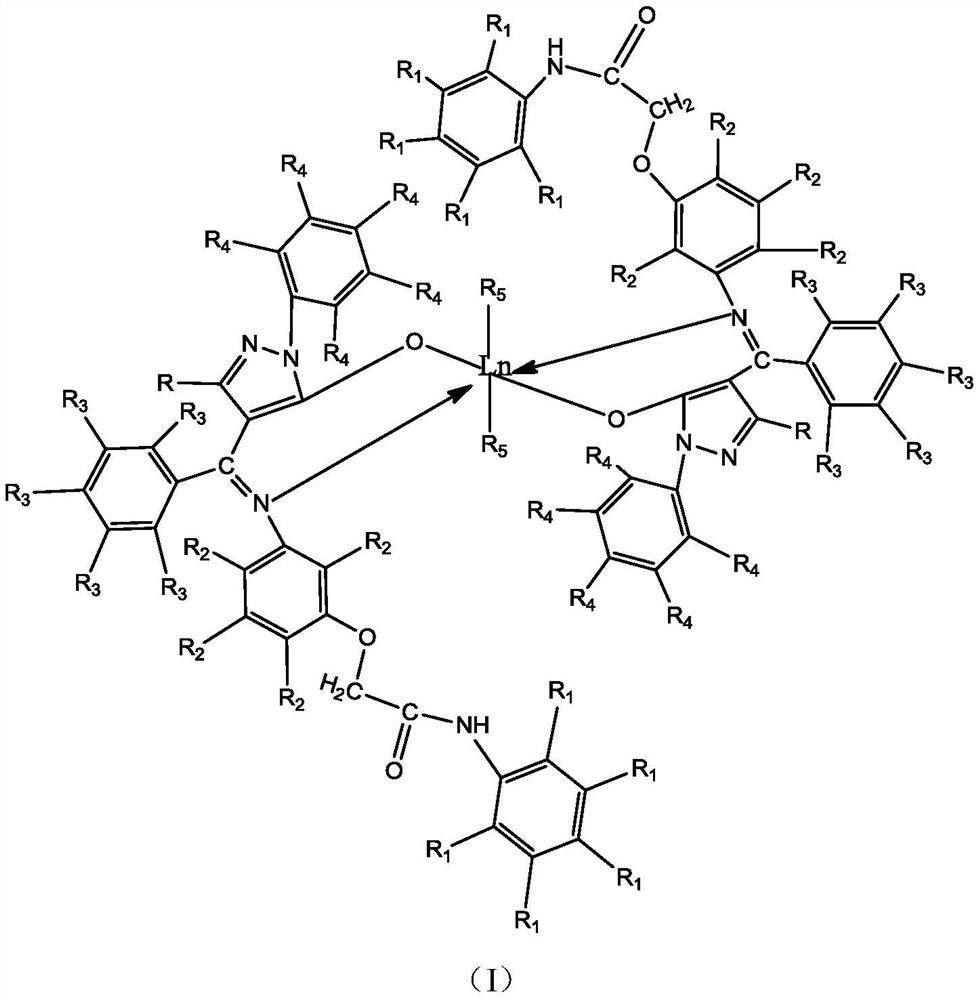

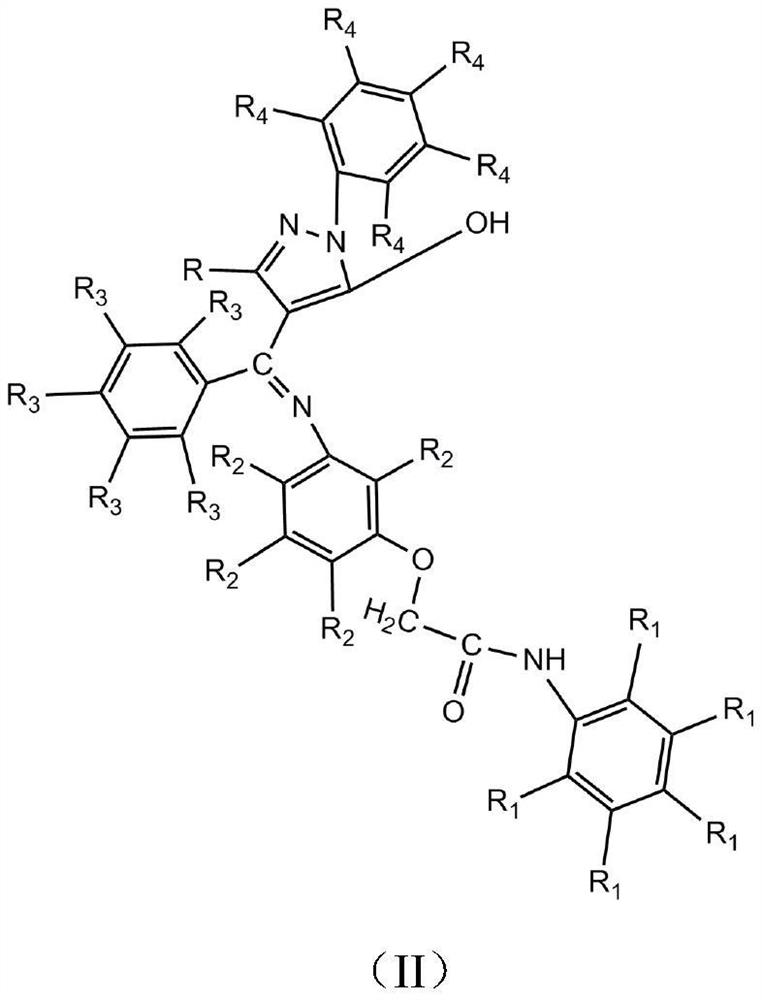

[0052] (1) Rare earth metal complex A (in formula (I), Ln is scandium, R is methyl, R 1 , R 2 , R 3 , R 4 are hydrogen, R 5 for the preparation of nitrate compounds)

[0053] The ligand structure is shown in formula (II), wherein R is a methyl group, R 1 , R 2 , R 3 , R 4 Both are hydrogen. Will be dissolved with 0.10mmol rare earth salt (Ln(R 5 ) 3 , Ln is scandium, R 5 Nitrate) in 2.0 mL of ethyl acetate solution was added dropwise to 2.0 mL of ethyl acetate solution in which 0.05 mmol of ligand was dissolved, a white precipitate was formed immediately, stirred at room temperature for 4 hours, centrifuged, washed with a small amount of ethyl acetate for 3 times, vacuum drying, yield 50%.

[0054] The elemental analysis data of the product is: C 62 h 50 N 10 o 12 Sc (found): C, 63.53 (63.52); H, 4.98 (4.98); N, 11.75 (11.77).

[0055] (2) Preparation of polylactide

[0056] At room temperature, add 10 μmol of rare earth metal complex A, 20 μmol of benzyl alc...

Embodiment 2

[0060] (1) The preparation of the rare earth metal complex is the same as in Example 1.

[0061] (2) Preparation of polylactide

[0062] At room temperature, add 10 μmol of rare earth metal complex A, 10 μmol of benzyl alcohol and 5 mL of toluene solvent into a 20 mL of anhydrous and oxygen-free polymerization bottle, react at 20°C for 5 minutes, add 40 mmol of lactide monomer, and stir at room temperature After 15 minutes, the ethanol solution of hydrochloric acid with a volume concentration of 10v% was added to terminate the reaction, the reaction solution was poured into ethanol for sedimentation, filtered to obtain a white solid, and the white solid was dried in a vacuum oven at 40°C for 48 hours to obtain a polylactide solid.

[0063] According to the nuclear magnetic resonance test, the conversion rate was 91%.

[0064] GPC analysis records the number average molecular weight M of polylactide n is 0.75 million, polydispersity coefficient M w / M n is 1.27.

Embodiment 3

[0066] (1) The preparation of the rare earth metal complex is the same as in Example 1.

[0067] (2) Preparation of polylactide

[0068] At room temperature, add 10μmol of rare earth metal complex A, 20μmol of benzyl alcohol and 50mL of toluene solvent into a 100mL anhydrous and oxygen-free polymerization bottle, react at 20°C for 5min, add 60mmol of lactide monomer, and stir at room temperature 1h, add ethanol solution of hydrochloric acid with a volume concentration of 10v% to terminate the reaction, pour the reaction solution into ethanol for sedimentation, filter to obtain a white solid, dry the white solid in a vacuum oven at 40°C for 48h to obtain a polylactide solid.

[0069] According to the nuclear magnetic resonance test, the conversion rate was 93%.

[0070] GPC analysis records the number average molecular weight M of polylactide n 188,000, polydispersity coefficient M w / M n is 1.19.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Polydispersity coefficient | aaaaa | aaaaa |

| Polydispersity coefficient | aaaaa | aaaaa |

| Polydispersity coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com