Woodworking tool wear state diagnosis method based on genetic BP neural network

A BP neural network and tool wear technology, applied in neural learning methods, biological neural network models, genetic laws, etc., can solve problems such as high signal noise, affecting image quality, affecting the accuracy of tool wear status diagnosis models, and avoiding gradients. Effects of Diffusion, Cost Reduction, Increased Computational Speed and Diagnostic Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

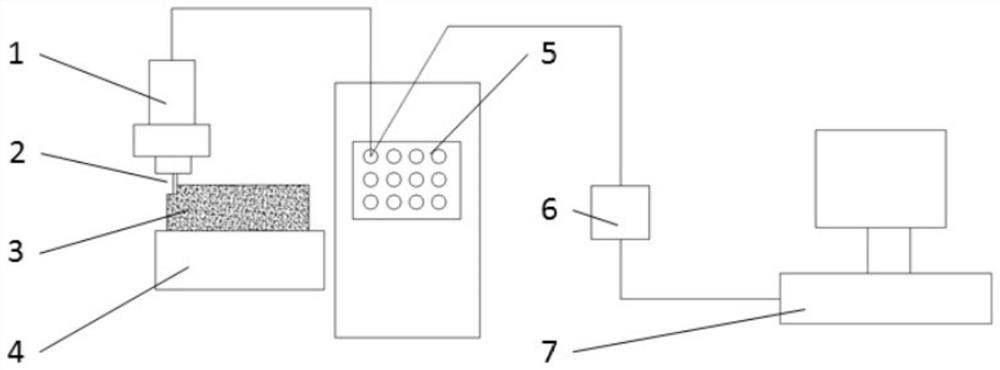

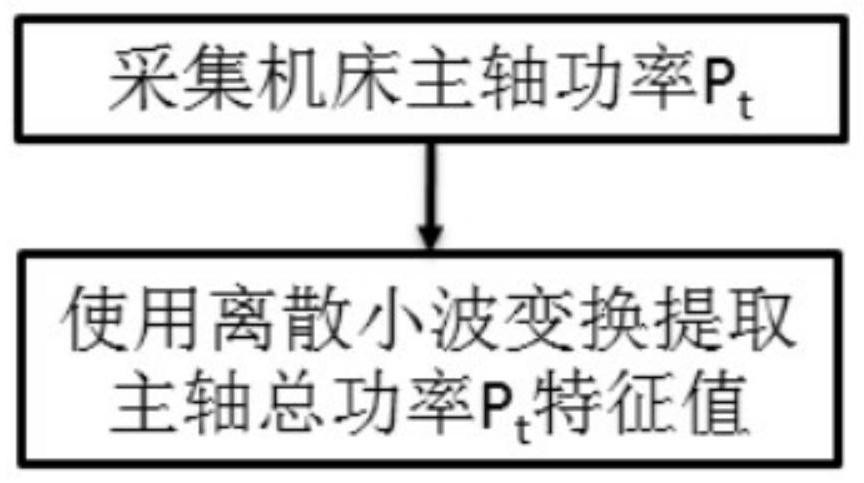

[0046] In order to prove the accuracy of the diagnostic method of this embodiment, a verification test was carried out in a numerical control machining center of a wood factory. Wood-plastic composite (WPC) is milled with a shank milling cutter with a diameter of 18mm. According to the experimental cutting parameters in Table 2, the power analyzer WT500 is used to collect the machine tool spindle power P t , to create a sample set.

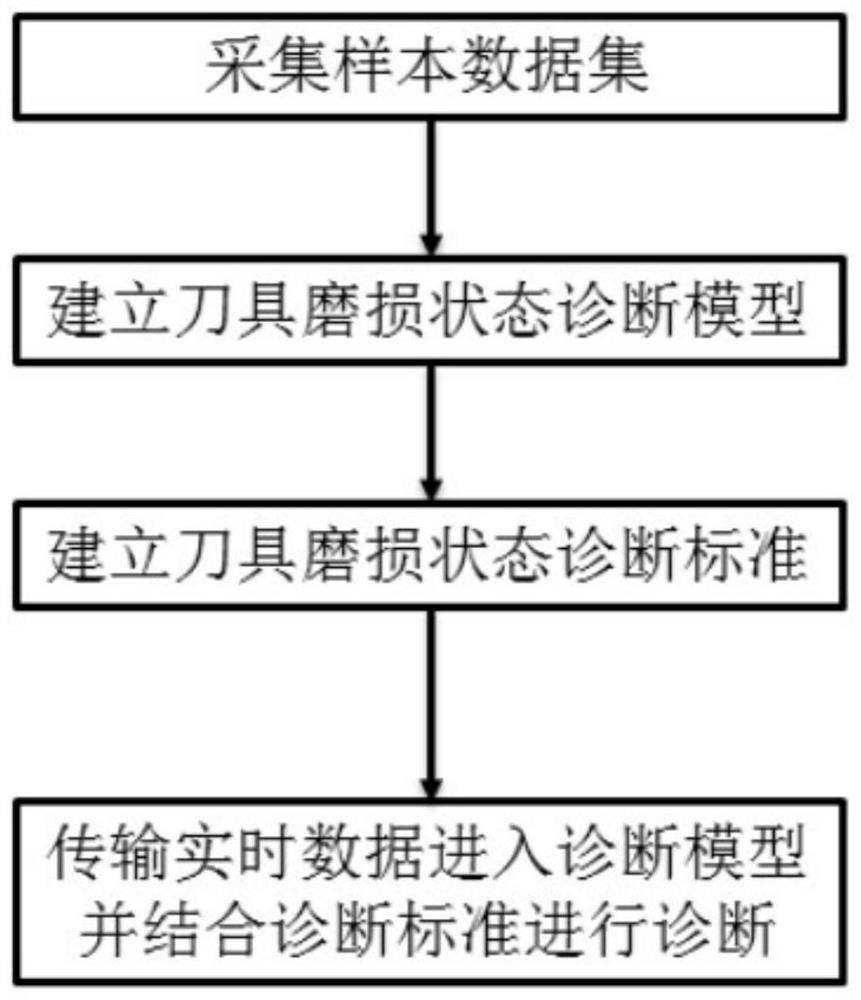

[0047] Such as figure 1 As shown, a kind of woodworking tool wear state diagnosis method based on machine tool spindle power and genetic BP neural network of the present invention comprises the following steps:

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap