Porous conductive ceramic material for heating electronic cigarette set and preparation method thereof

A technology of porous conductive and ceramic materials, applied in heating element materials, ceramic products, applications, etc., can solve the problems of restricting the expansion of ceramic heating elements, complicated preparation process, peculiar smell of e-liquid, etc., to improve heating uniformity and heating efficiency, The effect of expanding application fields and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh 6.3 g of TiBCN powder, 0.6 g of flocculent solid polyvinyl alcohol, and 1.5 g of bio-glass powder, add them to the ball mill according to the ratio of balls to material 10:1, and take them out after ball milling and mixing for 5 hours, and add NH 4 HCO 3 The crystal grains were 6 g, and the mixed powder was obtained by mechanical stirring for 30 min.

[0040] After the mold was lubricated with graphite lubricant, 10 g of the above mixed powder was added to the mold and placed on a hydraulic press to press and form to obtain a molded sample of 25.5 mm × 14.5 mm × 10 mm.

[0041] Put the pressed molded sample into the muffle furnace, heat it to 250°C at a heating rate of 5°C / min, and keep it for 1.5 hours, then quickly heat it up to 1300°C at a heating rate of 100°C / min, and then use The temperature was raised to 1500°C at a heating rate of 20°C / min, and after holding for 2.5 hours, the temperature was naturally cooled and cooled to room temperature to obtain a hig...

Embodiment 2~4

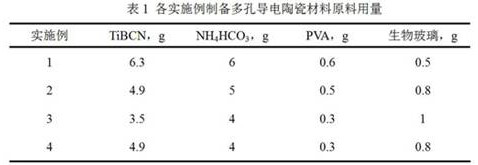

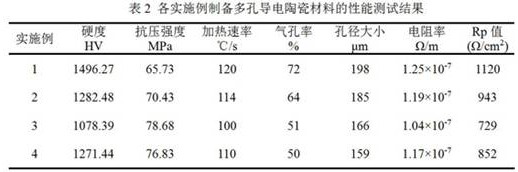

[0050] Various raw materials were prepared according to the dosages in Table 1, and porous conductive ceramic materials for heating electronic cigarettes were prepared according to the method of Example 1. According to the test method in Example 1, the porous conductive ceramic materials prepared in each example were tested, and the specific test results are listed in Table 2.

[0051]

[0052]

[0053] Relevant information reports that the hardness of the heating wire material for traditional electronic cigarettes is 190-275HV, and the resistivity is 1.1×10 -6 ~1.5×10 -6 Ω / m. It can be seen from Table 2 that the hardness and resistivity of the porous conductive ceramic material of the present invention are obviously better than those of the traditional heating wire. Moreover, the resistivity of the material prepared by the present invention is one order of magnitude lower than that of the traditional material, which also shows that the heating rate of the porous condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com