Preparation method of wear-resistant self-lubricating gradient coating for crane wheel

A gradient coating and powder spraying technology, which is applied in the coating, metal material coating process, fusion spraying, etc., can solve the problem of affecting the service life of the wear-resistant protective coating, the friction coefficient of the friction system is large, shrinkage cavities or blisters, etc. problems, to achieve the effect of retaining the content and uniform distribution of ingredients, reducing the friction coefficient and increasing the weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

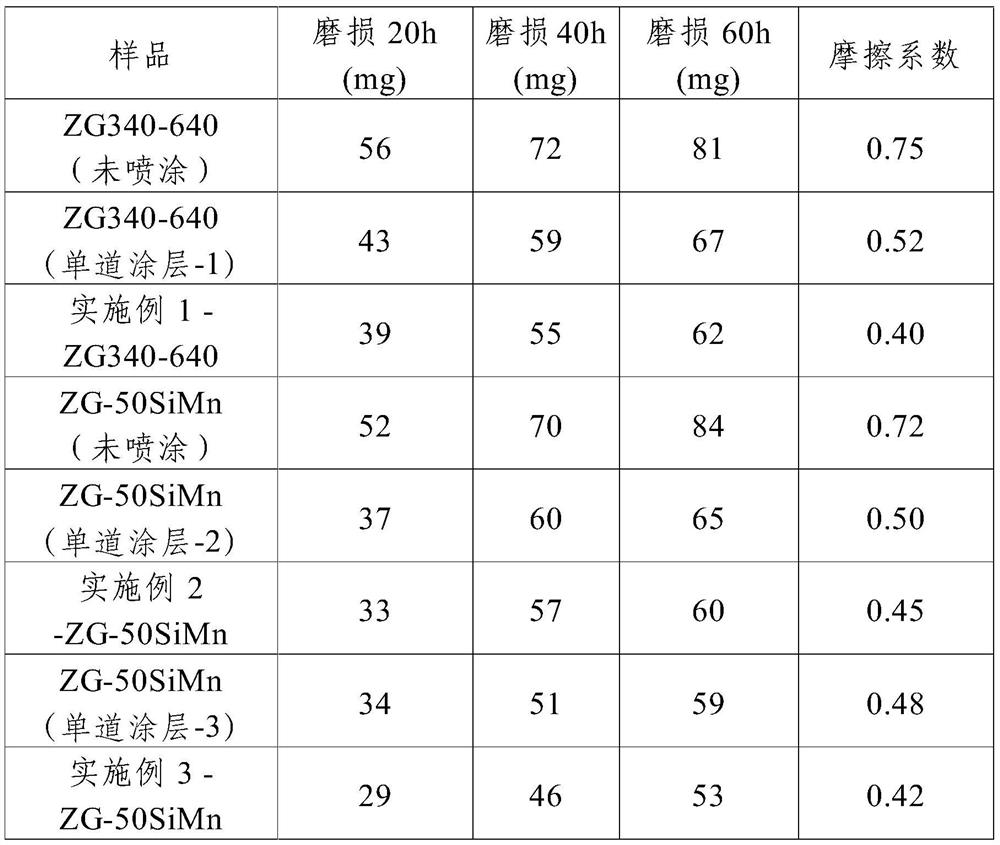

Examples

Embodiment 1

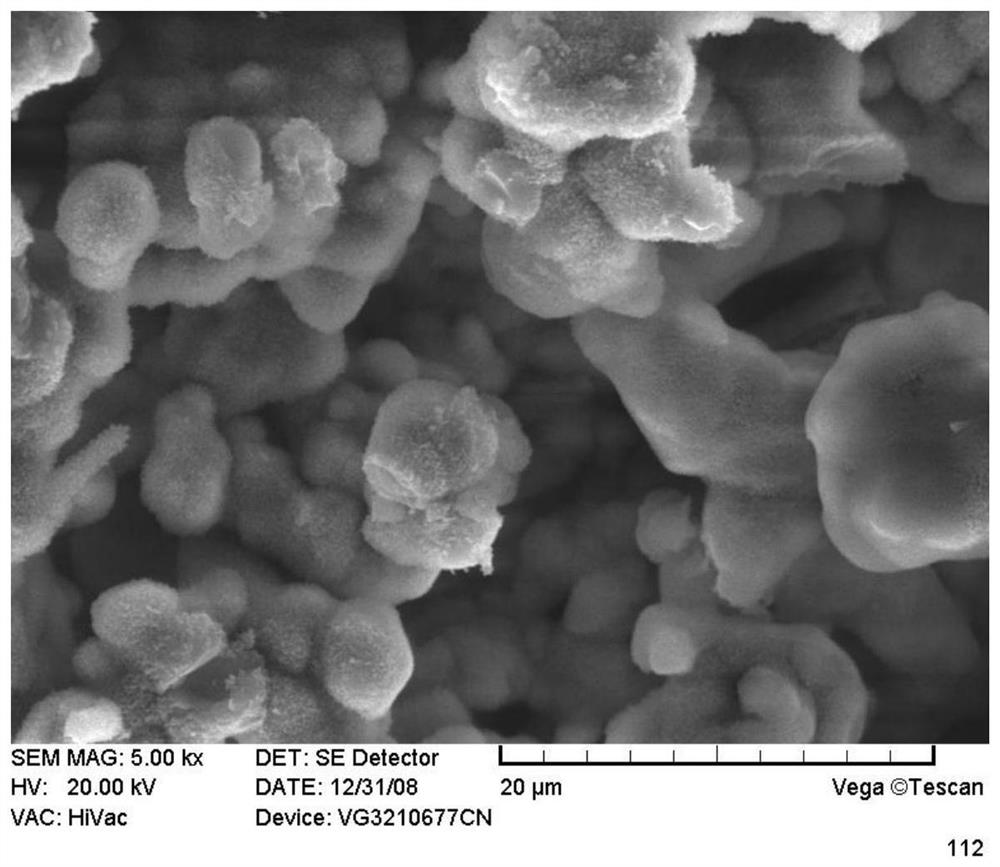

[0037] The preparation method of the wear-resistant self-lubricating gradient coating for crane wheels of the present embodiment includes the following steps:

[0038] Step 1. Molybdenum trioxide powder (MoO 3 The mass content is greater than 99%, the average particle size is less than 10 μm), and the drying temperature is 80 ° C and the time is 1 h to obtain dry powder; the dry powder is placed in a sintering furnace, and the sintering furnace is continuously passed through. The mixed gas of carbon monoxide and argon is added for sintering, the heating rate of sintering is 6°C / min, the sintering temperature is 900°C, and the holding time is 10min to obtain molybdenum carbide powder; the volume of carbon monoxide in the mixed gas of carbon monoxide and argon The percentage is 20%, and the balance is argon; the atmospheric pressure of the carbon monoxide and argon mixed gas is 0.2MPa;

[0039] Step 2, the graphene powder (commercially enhanced graphene, the specific surface ar...

Embodiment 2

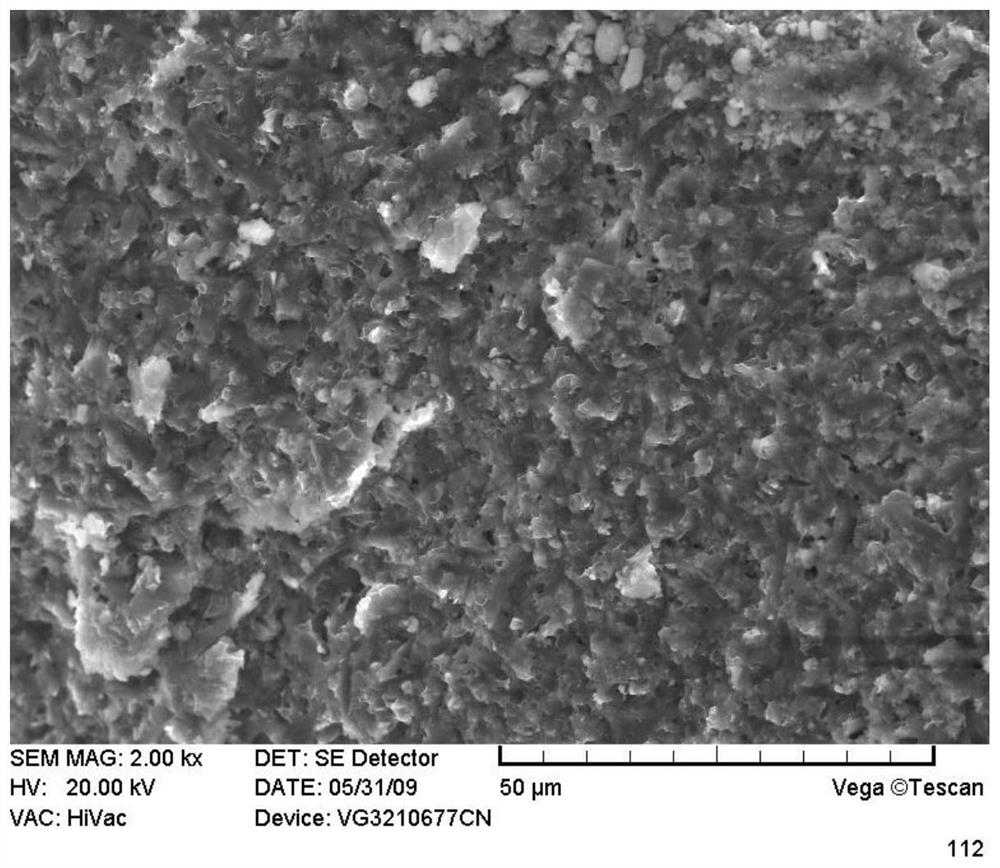

[0053] The preparation method of the wear-resistant self-lubricating gradient coating for crane wheels of the present embodiment includes the following steps:

[0054] Step 1. Molybdenum trioxide powder (MoO 3The mass content is greater than 99%, the average particle size is less than 10 μm), and the drying temperature is 100 ° C and the drying time is 1.5 h to obtain dry powder; The mixed gas of carbon monoxide and argon is introduced for sintering, the heating rate of sintering is 7°C / min, the sintering temperature is 1000°C, and the holding time is 15min to obtain molybdenum carbide powder; The volume percentage is 30%, and the balance is argon; the atmospheric pressure of the carbon monoxide and argon mixed gas is 0.3MPa;

[0055] Step 2, the graphene powder (commercially enhanced graphene, the specific surface area is 180m 2 / g~280m 2 / g, the C content is 70% to 80%, the average particle size is less than 10 μm) and anhydrous ethanol are mixed uniformly, and then deion...

Embodiment 3

[0068] The preparation method of the wear-resistant self-lubricating gradient coating for crane wheels of the present embodiment includes the following steps:

[0069] Step 1. Molybdenum trioxide powder (MoO 3 The mass content is greater than 99%, the average particle size is less than 10 μm), and the drying temperature is 120 ° C and the drying time is 2 hours to obtain dry powder; the dry powder is placed in the sintering furnace, and the sintering furnace is continuously passed through. A mixed gas of carbon monoxide and argon is added for sintering, the heating rate of sintering is 8°C / min, the sintering temperature is 1100°C, and the holding time is 20min to obtain molybdenum carbide powder; the volume of carbon monoxide in the mixed gas of carbon monoxide and argon The percentage is 40%, and the balance is argon; the atmospheric pressure of the carbon monoxide and argon mixed gas is 0.4MPa;

[0070] Step 2, the graphene powder (commercially enhanced graphene, the specif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com