Preparation method and application of g-C3N4-@CeO2 composite catalyst

A composite catalyst, g-c3n4 technology, applied in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve problems such as increased cost, inability to be put into practical application on a large scale, and long aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

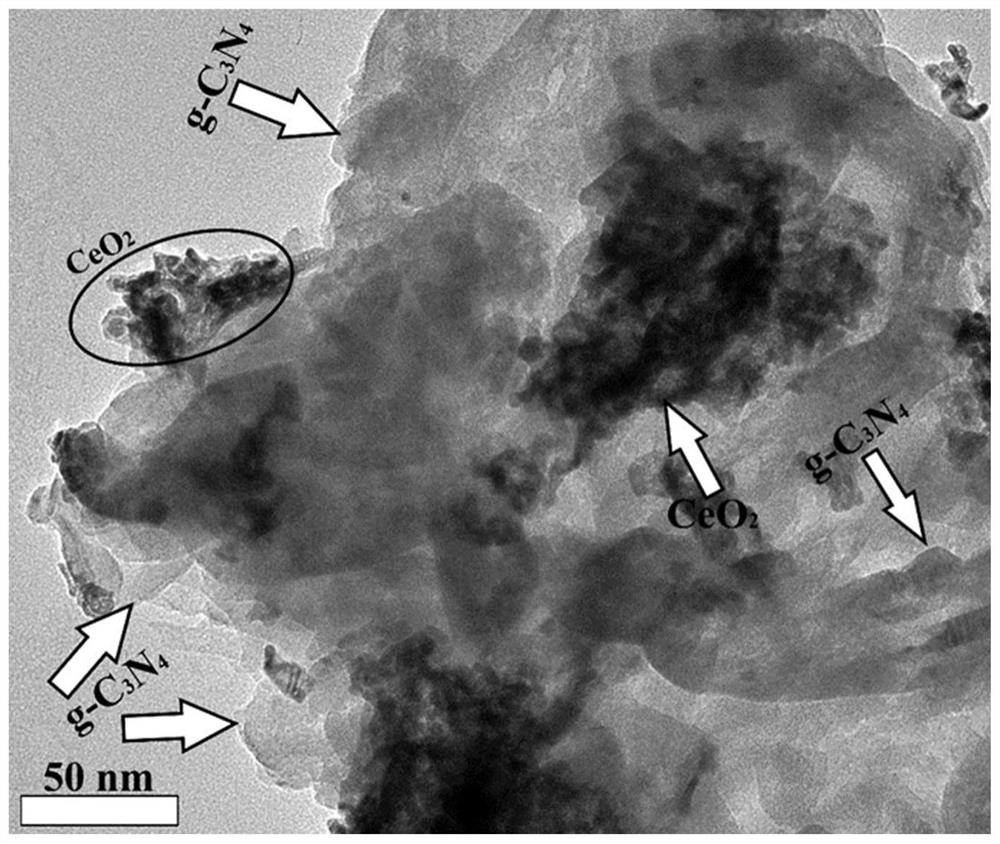

[0042] The main idea of the embodiment of the present invention is: a g-C 3 N 4 @CeO 2 The preparation method of composite catalyst comprises the steps:

[0043] The graphitic carbon nitride (g-C 3 N 4 ) The monomer material is dispersed in deionized water, and the dispersion I is obtained after ultrasonic treatment;

[0044] Ceria (CeO 2 ) The monomer material is dispersed in deionized water, and the dispersion II is obtained after ultrasonic treatment:

[0045] Add the dispersion I to the dispersion II dropwise under stirring to obtain a mixed dispersion;

[0046] The resulting mixed dispersion is continuously stirred to obtain a dispersed solution of the reaction product;

[0047] The reaction product is centrifuged and dried to obtain g-C containing 3 N 4 The composite catalyst whose mass proportion is 5-35wt%.

[0048] Unless otherwise specified, various raw materials, reagents, instruments and equipment used in the examples of the present invention can be pur...

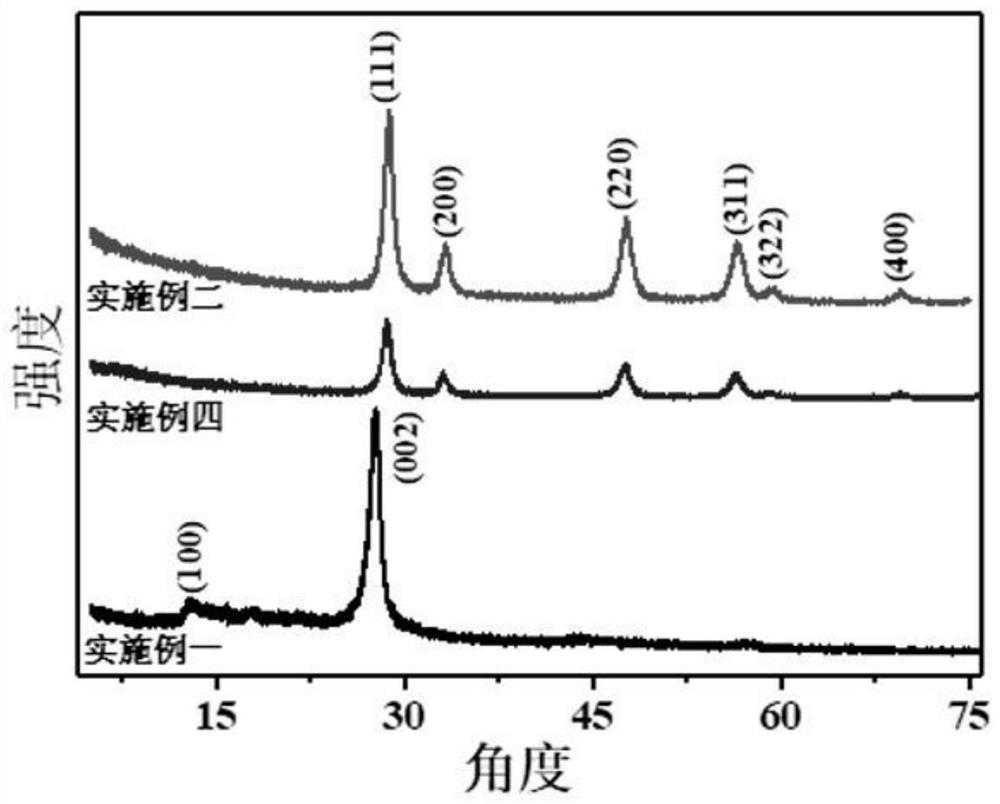

Embodiment 1

[0050] With 50.0g of melamine (C 2 h 4 N 4 ) into a clean beaker, then place the beaker in an electric blast drying oven and dry at 60°C for 24 hours, seal the dried beaker filled with melamine with plastic wrap, and then place it in a desiccator. Weigh 8.0g of dry melamine and pour it into a clean porcelain crucible, cover it, then place the porcelain crucible in a muffle furnace, adjust the temperature to 580°C under programmed temperature rise, and then keep it at 580°C for 4h, the program The heating rate was 2°C / min. After the calcination was finished and the porcelain crucible was naturally cooled to room temperature, the porcelain crucible was taken out, the calcined product was fully ground and then transferred into a sample tube and labeled to obtain graphite phase carbon nitride (g-C 3 N 4 ) monomer catalyst material. for use in the following examples.

Embodiment 2

[0052] Accurately weigh 4.3422g cerium nitrate hexahydrate with an analytical balance, pour the weighed cerium nitrate hexahydrate into a clean porcelain crucible and cover it, then put the crucible into a muffle furnace and calcinate at a temperature of 500°C 240min, the temperature program rate is 2°C / min, after the crucible is naturally cooled to room temperature, take out the porcelain crucible, take out the calcined product, and obtain a light yellow powder after sufficient grinding, and finally obtain nano-ceria (CeO 2 )Material. for use in the following examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com