Preparation method and application of a continuous electron-donating iron-based metal-organic framework composite material

An organic framework, iron-based metal technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the waste of nano-iron materials and reduce the utilization efficiency of nano-iron and other problems to achieve the effect of ensuring degradation ability, improving utilization efficiency and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

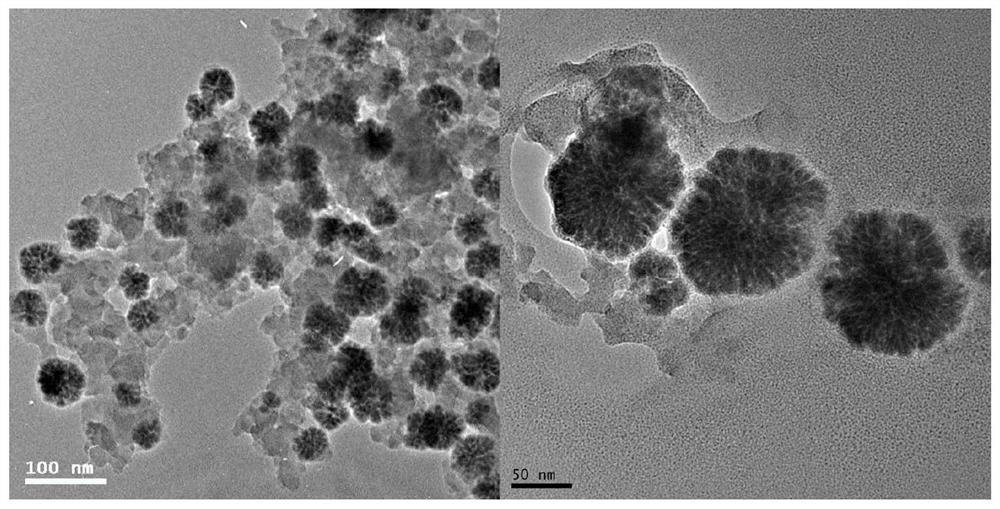

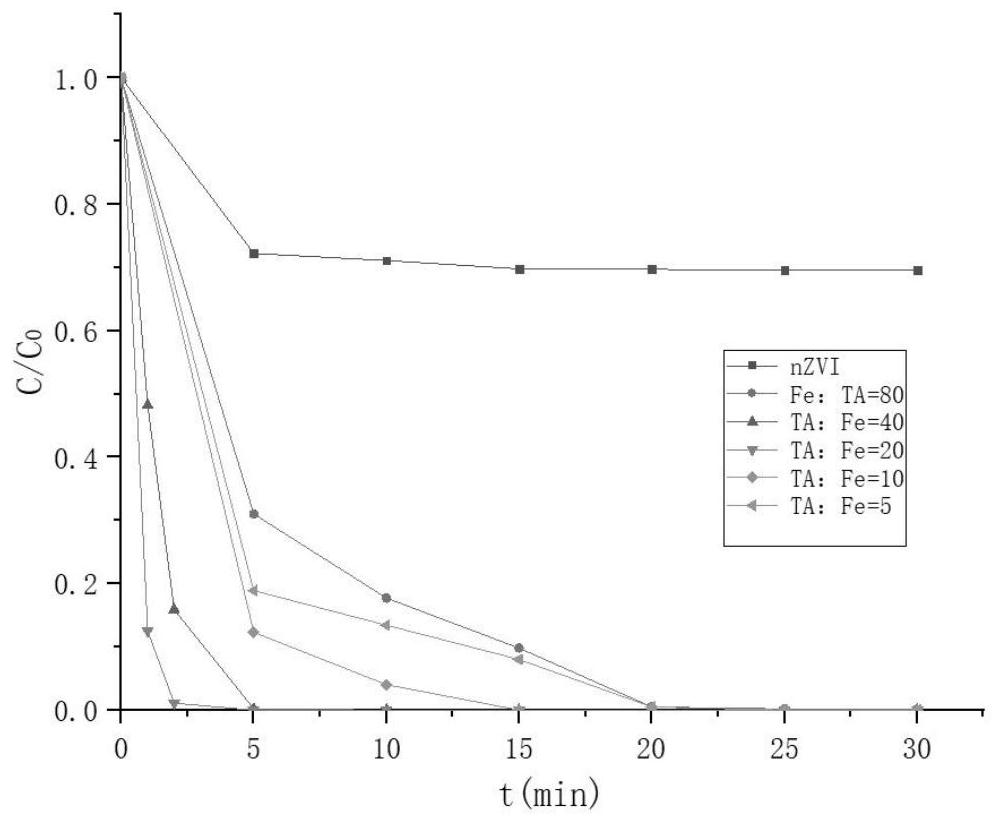

[0027] (1) Measure 45ml of deionized water and place it in a three-necked flask for deoxygenation for 20min, add 0.3046g of tannic acid, stir and dissolve fully, and obtain an organic framework solution.

[0028] (2) Add 0.2420g FeCl to the organic framework solution obtained in step (1) 3 ·6H 2 O(FeCl 3 ·6H 2 The molar ratio of O to tannic acid is 1:5), stirring at 1000r / min rotation speed for 0.3h to make it fully mixed to obtain a metal organic solution.

[0029] (3) Under stirring conditions, dropwise add 5 mL of sodium borohydride aqueous solution with a concentration of 0.54 mol / L to the above-mentioned system, and continue to stir the reaction for 30 min after the dropwise addition to ensure that the reaction is complete.

[0030] (4) After the reaction, the nano-iron particles were separated by magnetic separation, and then washed three times with deionized water and absolute ethanol, respectively, and the iron-based metal organic framework material was obtained aft...

preparation Embodiment 2

[0032] (1) Measure 45ml of deionized water and put it in a three-necked flask to deoxygenate for 20min, add 0.1523g of tannic acid, stir and dissolve fully, and obtain an organic framework solution.

[0033] (2) Add 0.2420g FeCl to the organic framework solution obtained in step (1) 3 ·6H 2 O(FeCl 3 ·6H 2 The molar ratio of O to tannic acid is 1:10), stirring at 1000r / min rotation speed for 0.3h to make it fully mixed to obtain a metal organic solution.

[0034] (3) Under stirring conditions, dropwise add 5 mL of sodium borohydride aqueous solution with a concentration of 0.54 mol / L to the above-mentioned system, and continue to stir the reaction for 30 min after the dropwise addition to ensure that the reaction is complete.

[0035] (4) After the reaction, the nano-iron particles were separated by magnetic separation, and then washed three times with deionized water and absolute ethanol, respectively, and the iron-based metal organic framework material was obtained after v...

preparation Embodiment 3

[0037] (1) Measure 45ml of deionized water and place it in a three-necked flask to deoxygenate for 20min, add 0.0762g of tannic acid, stir and dissolve fully, and obtain an organic framework solution.

[0038] (2) Add 0.2420g FeCl to the organic framework solution obtained in step (1) 3 ·6H 2 O(FeCl 3 ·6H 2 The molar ratio of O to tannic acid is 1:20), stirring at 1000r / min rotation speed for 0.3h to make it fully mixed to obtain a metal organic solution.

[0039] (3) Under stirring conditions, dropwise add 5 mL of sodium borohydride aqueous solution with a concentration of 0.54 mol / L to the above-mentioned system, and continue to stir the reaction for 30 min after the dropwise addition to ensure that the reaction is complete.

[0040](4) After the reaction, the nano-iron particles were separated by magnetic separation, and then washed three times with deionized water and absolute ethanol, respectively, and the iron-based metal organic framework material was obtained after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com