Copper alloy with capillary core structures on surface and preparation method thereof

A technology of copper alloy and capillary core, which is applied in the field of materials, can solve problems such as insufficient yield, poor bonding force, and limited use, and achieve the effects of low cost, improved stability, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a copper alloy, which includes the following components in parts by mass: 90-100 parts of copper, 1-8 parts of nickel, 0.1-5 parts of tin, 0.05-1 part of chromium, and 0.01-0.3 parts of phosphorus parts, vanadium 0.01-0.2 parts.

[0033] Specifically, the copper alloy preferably includes the following components in parts by mass: copper 92-98 parts, nickel 3-5 parts, tin 0.5-2 parts, chromium 0.1-0.5 parts, phosphorus 0.05-0.15 parts, vanadium 0.01- 0.1 part.

[0034] In practical application, the mass fraction of copper in copper alloy can be 92 parts, 93 parts, 94 parts, 95 parts, 96 parts, 97 parts, 98 parts, etc. Although copper has very high thermal conductivity, copper itself There are a series of problems such as low hardness, low strength, and poor corrosion resistance under alkaline conditions. The addition of nickel, tin, chromium, phosphorus, and vanadium can just solve the above problems.

[0035] Nickel can be infinitely miscible ...

Embodiment 2

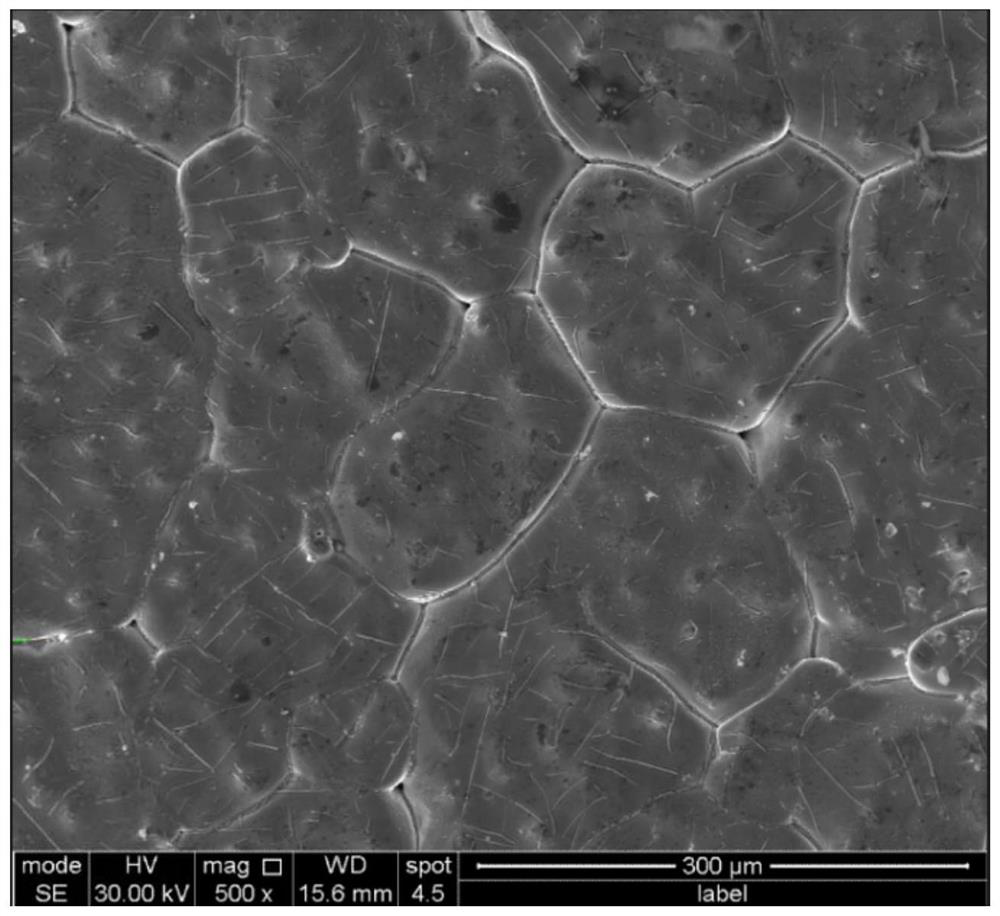

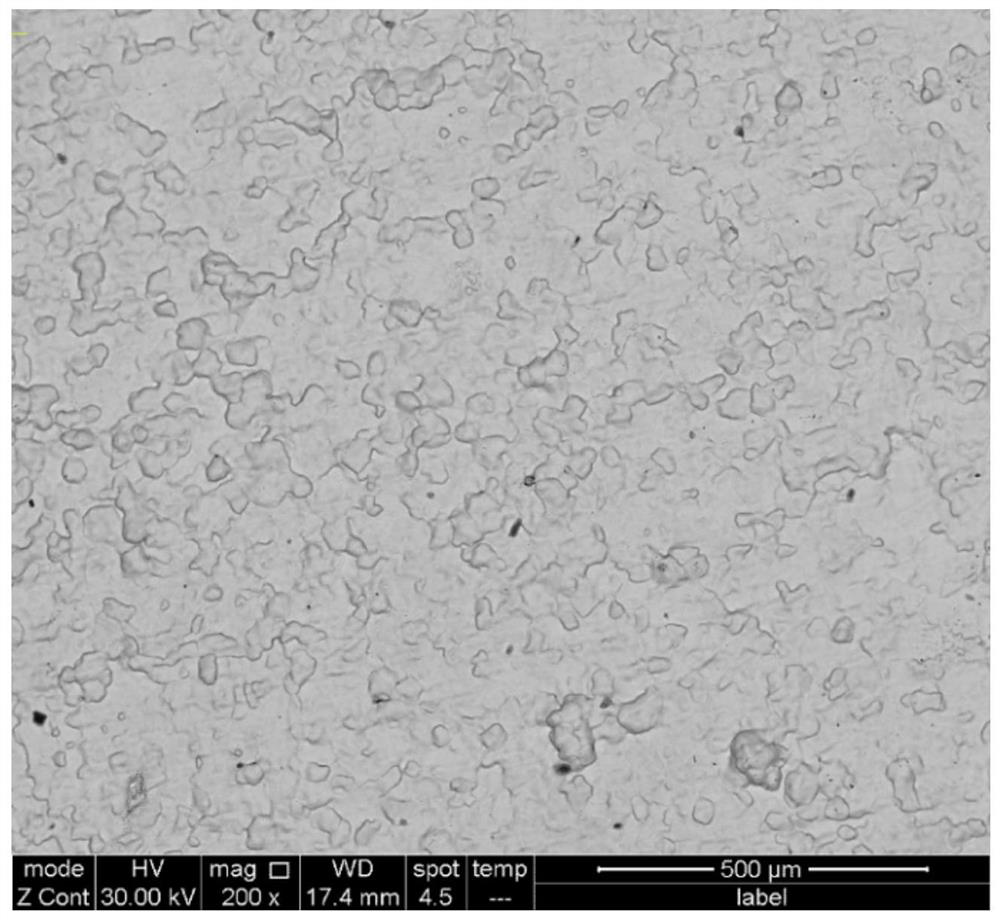

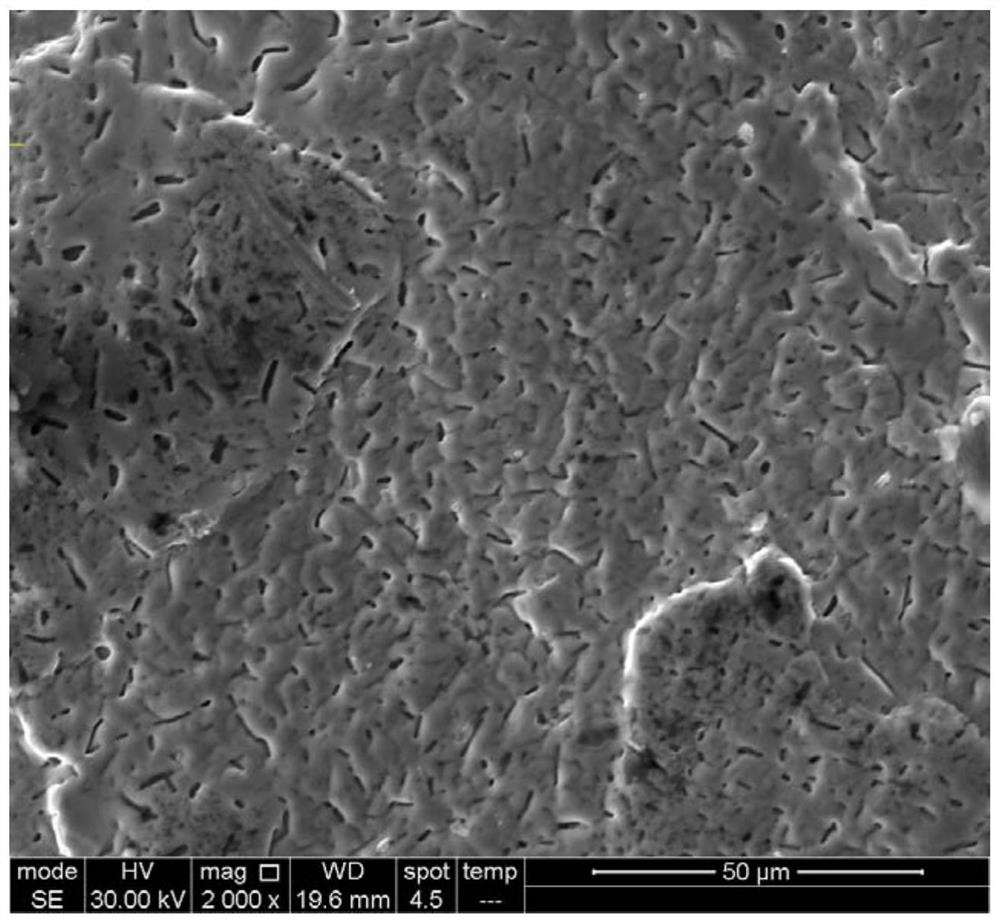

[0044] On the basis of Embodiment 1, this embodiment provides a copper alloy having a capillary core structure on the surface, and the surface of the copper alloy has a capillary core structure of 1-10 μm.

[0045] The copper alloy described in Example 1 is subjected to alkali solution corrosion and high-temperature diffusion treatment sequentially, and a capillary core structure with excellent performance can be obtained. This is because the copper in the copper alloy is acid-resistant but not alkali-resistant, nickel is resistant to alkali but not acid-resistant, and alloying elements such as chromium and vanadium are both acid-resistant and alkali-resistant. Therefore, the surface of the copper alloy is micro-etched with an alkaline solution to corrode part of the copper. Prefabricated initial micropores will be formed, and further high-temperature thermal diffusion treatment will be carried out. Because the high-temperature diffusion rates of copper and nickel elements are ...

Embodiment 3

[0048] This embodiment provides a method for preparing a copper alloy having a capillary core structure on the surface, including steps S1 to S6.

[0049] S1. Smelting: Put copper into the melting furnace, heat up to the preset melting temperature, after the copper is completely melted, add vanadium, chromium, nickel, phosphorus and tin in sequence, and obtain the primary copper alloy product after cooling.

[0050] The preset smelting temperature is preferably 1100-1250°C, specifically 1110°C, 1150°C, 1200°C, 1250°C, etc., which is not limited in the present application.

[0051] S2. Hot rolling: hot rolling the copper alloy primary product at a preset hot rolling temperature.

[0052] The preset hot rolling temperature is preferably 700-950°C, specifically 700°C, 750°C, 800°C, 850°C, 900°C, 950°C, etc., which is not limited in this application. In practical application, the deformation amount of the copper alloy preliminary product in this step is not less than 50%.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com