Pressure bearing container of heat accumulating type heater

A heater and heat storage technology, which is applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems affecting air heat exchange results and test results, and achieve airflow uniformity and service life Effect of long and stable load-bearing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

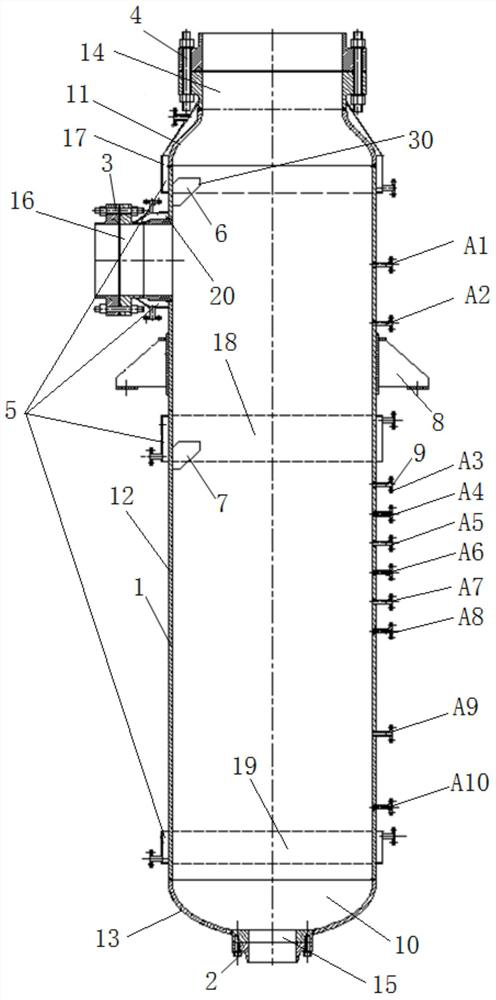

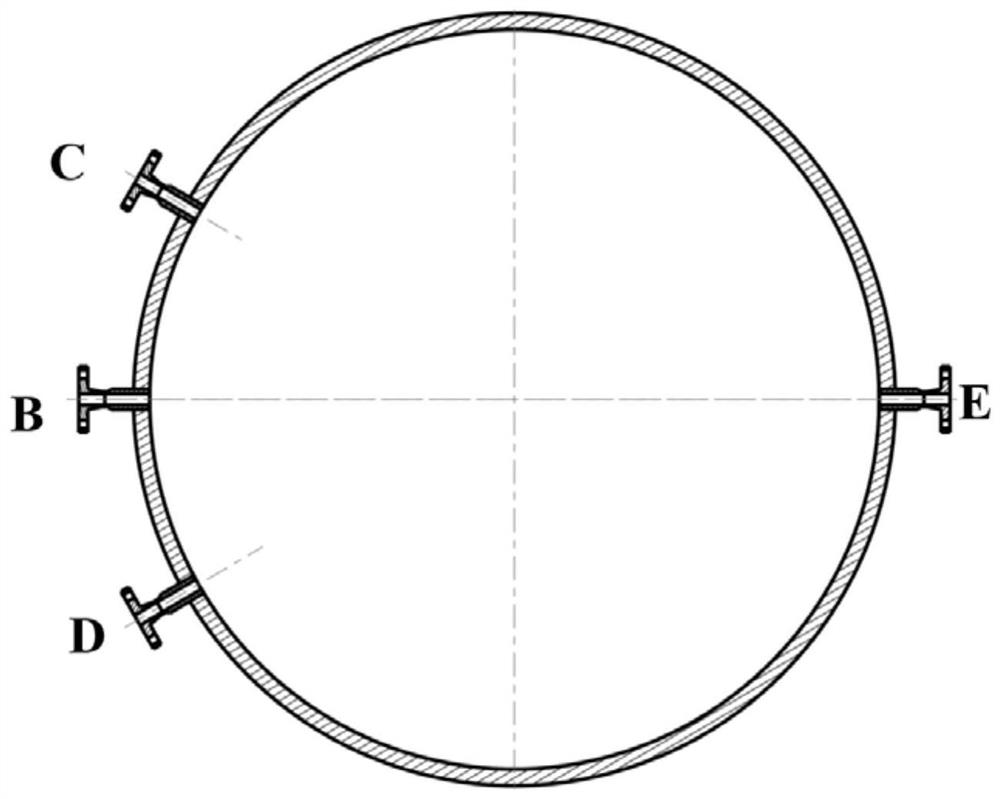

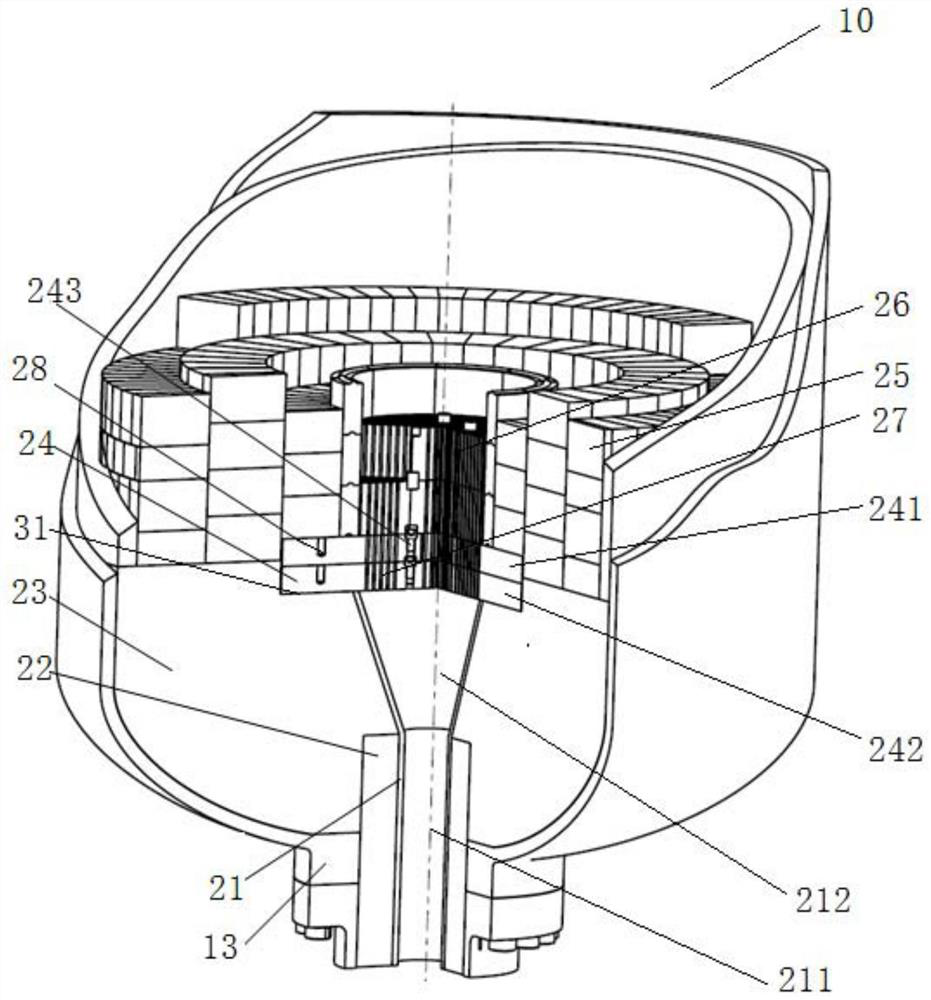

[0053] This implementation provides a specific structure of the pressure bearing container of the regenerative heater, which is used to load the hollow brick regenerator and the refractory material of the heat insulation layer, such as figure 1 As shown, it includes outer casing 1, gas outlet tee matching flange 2, high-temperature air outlet matching flange 3, burner matching flange 4, water-cooling jacket assembly 5, upper anchor group 6, lower anchor group 7, Ear support 8, temperature measuring flange 9 and bottom support structure 10;

[0054] Shell

[0055] Such as figure 1 As shown, the outer casing 1 is composed of a top conical head 11, a middle cylindrical body 12 and a bottom spherical head 13; in this embodiment, the outer casing 1 is made of carbon steel Q345R as a whole, and the surface is painted with high-temperature resistant anti-rust paint or Coating, the temperature resistance is not lower than 400°C, and the specific structure includes: the small-diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com