Instant flavored fermented fish soft can and preparation method thereof

A technology of fermented fish and soft cans, which is applied in the direction of food ingredients as odor improvers, food ingredients as taste improvers, and food preservation. It can solve the problems of affecting product appearance, undeveloped ready-to-eat snack foods, and fish rot and deterioration. Effects of eliminating fishy and bad smell substances, reducing bad smell and taste, and promoting balanced distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

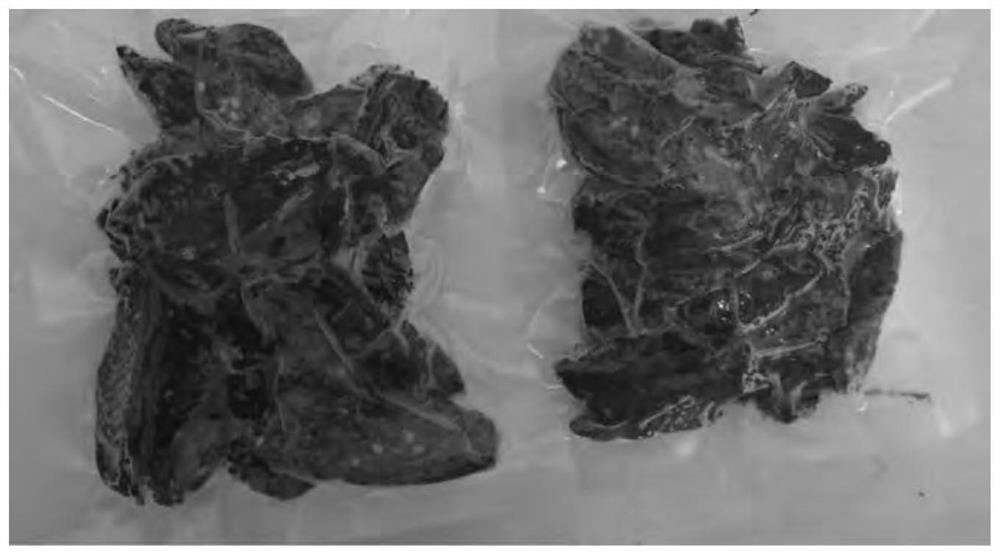

[0046] After thawing and washing 10 kg of frozen Balang fish, remove the head, scale, tail, viscera and wash. Soak the fish body in 5% salt water for 0.5h, then cook it in 5% sucrose water for 5min, remove it, and drain it; the drained fish body is dried with hot air at a drying temperature of 35°C and a drying time of 6 hours; Extrude and peel off the fish bones to obtain boneless or boneless fish fillets; mix the fish fillets with Rhizopus sweetus in a ratio of 100:1 (parts by weight), spray water, and seal and ferment for 3 days at 30°C; ferment the fish fillets without passing through Season again, and directly use high-temperature retort bags for vacuum packaging, the vacuum degree of which is above 0.08MPa; the fermented fish is boiled and sterilized even in the packaging bag, and the boiling time is 15 minutes. After sterilization, it is cooled naturally to obtain the instant flavor fermented fish soft can (See figure 1 ), the net weight of the fish meat is about 1.2 k...

Embodiment 2

[0048] 15 kg of fresh Balang fish, after cleaning, remove the head, scale, tail, viscera, and wash. Soak the fish body in 5% salt water for 1 hour, then cook it in 5% sucrose water for 8 minutes, remove it, and drain it; the drained fish body is dried with hot air at 40°C for 4 hours; the dried fish body is squeezed Press and peel off the fish bones to obtain boneless or boneless fish fillets; mix the fish fillets with lactic acid bacteria in a ratio of 100:3 (parts by weight), spray water, and seal and ferment at 42°C for 3 days; add about 40g of mixed seasoning to the fermented fish fillets (1 part, 1 part, 5 parts, 10 parts, 2 parts, 1 part, 1 part, 1 part by weight of sucrose, monosodium glutamate, edible oil, starch, chili, ginger powder, onion powder, soy sauce), stir and season The fish fillets are vacuum-packed in high-temperature retort bags with a vacuum degree of 0.08 MPa or more; the fermented fish is sterilized with packaging bags at a temperature of 115°C for 15 ...

Embodiment 3

[0050] After thawing and cleaning 10 kg of frozen Balang fish, remove the head, scale, tail, viscera and wash. Soak the fish body in 3% salt water for 0.5h, then cook it in 5% sucrose water for 10min, remove it, and drain it; the drained fish body is air-dried at 30°C for 8 hours; the dried fish body is squeezed Press, peel fish bone, obtain boneless or less bone fish fillet; Fish fillet is mixed with mixed strain (1 weight part of yeast, 1 weight part of rhizopus and 1 weight part of lactic acid bacteria) according to 100:0.5 (weight part) ratio mixes, Spray water and ferment for 3 days at 31°C; add about 35g of mixed seasoning (sucrose, monosodium glutamate, edible oil, starch, pepper, ginger powder, onion powder, soy sauce is 1 part, 1 part, 5 parts by weight) . , the sterilization temperature is 121 DEG C, the sterilization time is 10min, and after sterilization, it is naturally cooled to obtain the instant flavor fermented fish soft can (see Figure 7 ), the fish flesh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com