Flame-retardant polyurethane material and preparation method thereof

A polyurethane material and a flame-retardant technology, applied in the field of flame-retardant polyurethane materials and their preparation, can solve the problems of polyurethane water absorption defects that cannot be improved, single phosphorus-containing flame retardant, low flame retardant efficiency, etc., and achieve reduced performance. The effect of reducing, improving hydrophobicity and improving flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

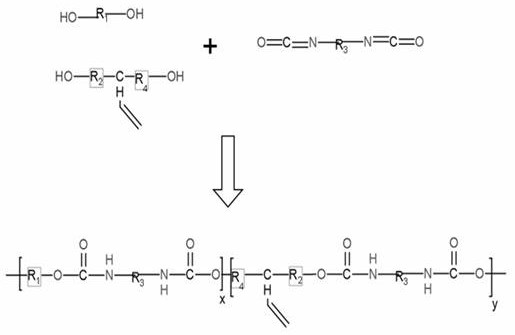

[0039] (1) Add 40g of polytetrahydrofuran, 10g of 6-heptene-2,4-diol, and 0.1g of hydroquinone into the reactor, and heat it to 80 while stirring at 200r / min. oC, evacuate to -0.04Mpa, keep 3h, remove the moisture in the alcohol, then pass nitrogen to normal pressure, lower the temperature, add 20g of hexamethylene diisocyanate, 0.01g of bis(dodecylthio) di ding tin, heated to 50 o C, reaction 4h, cooling obtains prepolymer;

[0040] (2) Add 1g1,4-butanediol, 5g spiroindane monomer, 5g methacryloylethoxy phosphate, 0.1g free radical initiator to the prepolymer, and heat while stirring at 200r / min to 50 o C, react for 3 hours, vacuumize to -0.04, keep for 3 hours, remove air bubbles, then inject the reaction solution into the mold, 100 o C continued to react for 8h, and cooled down to 50 o C aging for 48 hours to obtain a flame-retardant polyurethane material.

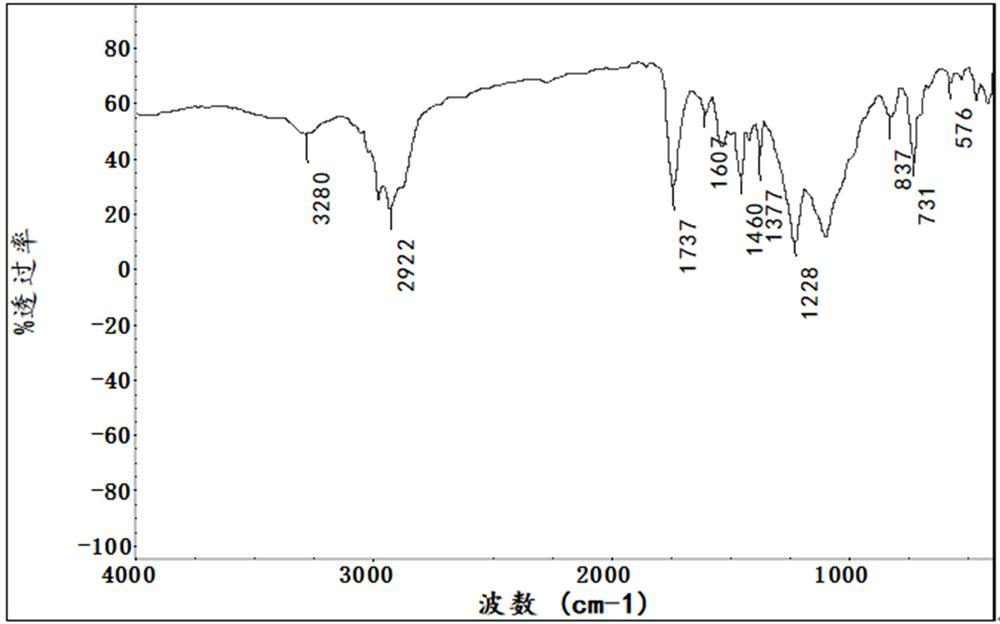

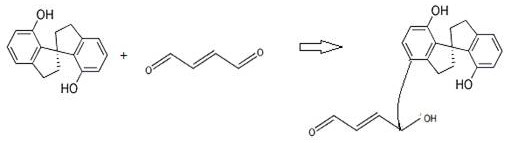

[0041] Further, the preparation method of the spiroindane monomer is:

[0042] Under nitrogen protection, 19g o...

Embodiment 2

[0045] (1) Add 45.7g of polypropylene glycol, 11.6g of androstenediol, and 0.3g of 1,4-p-benzoquinone into the reactor, and heat it to 89.6 while stirring at 200r / min. o C, evacuate to -0.06Mpa, keep for 2.4h, remove the moisture in the alcohol, then pass nitrogen to normal pressure, cool down, add 21.2g of biuret triisocyanate, 0.03g of tetramethylguanidine, and heat to 57.4 o C, react for 3.5h, cool down to obtain prepolymer;

[0046] (2) Add 1.7g 1,4-bishydroxyethoxybenzene, 5.9g spirodihydroindene monomer, 6.1g ethylene glycol methacrylate phosphate, 0.3g free radical initiator to the prepolymer, 200r / Min heated to 54.6 while stirring o C, react for 2.6 hours, vacuumize to -0.06, keep for 2.3 hours, remove air bubbles, then inject the reaction solution into the mold, 105.2 o C continued to react for 6.9h and cooled down to 47.4 o C aging for 42.1h, a flame-retardant polyurethane material was obtained.

[0047] Further, the preparation method of the spiroindane monomer...

Embodiment 3

[0051] (1) Add 48.7g of polycarbonate diol, 13.9g of 6-heptene-2,4-diol, and 0.5g of 2-tert-butylhydroquinone into the reactor, stirring at 200r / min side heat to 102 o C, evacuate to -0.08Mpa, keep 2h, remove the moisture in the alcohol, then pass nitrogen to normal pressure, cool down, add 23.6g of 1,5-naphthalene diisocyanate, 0.05g of stannous oxalate, and heat to 64.4 o C, reacted for 2.8h, and cooled to obtain a prepolymer;

[0052] (2) Add 2.4g glycerol, 6.6g spiroindene monomer, 6.8g SPMA, 0.4g free radical initiator to the prepolymer, heat to 57.9g while stirring at 200r / min o C, react for 2.1h, vacuumize to -0.08, keep for 1.7h, remove air bubbles, then inject the reaction solution into the mold, 109.5 o C continued to react for 5.8h and cooled down to 44.7 o C aging for 36.7 hours to obtain a flame-retardant polyurethane material.

[0053] Further, the preparation method of the spiroindane monomer is:

[0054] Under nitrogen protection, 22g of maleic dialdehyde ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com