Hydrophobic low-density high-strength polystyrene microspheres and preparation method thereof

A polystyrene microsphere, hydrophobic technology, used in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of inapplicability and poor hydrophobicity, and achieve strong hydrophobic performance and The effect of long-lasting stability and high binding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

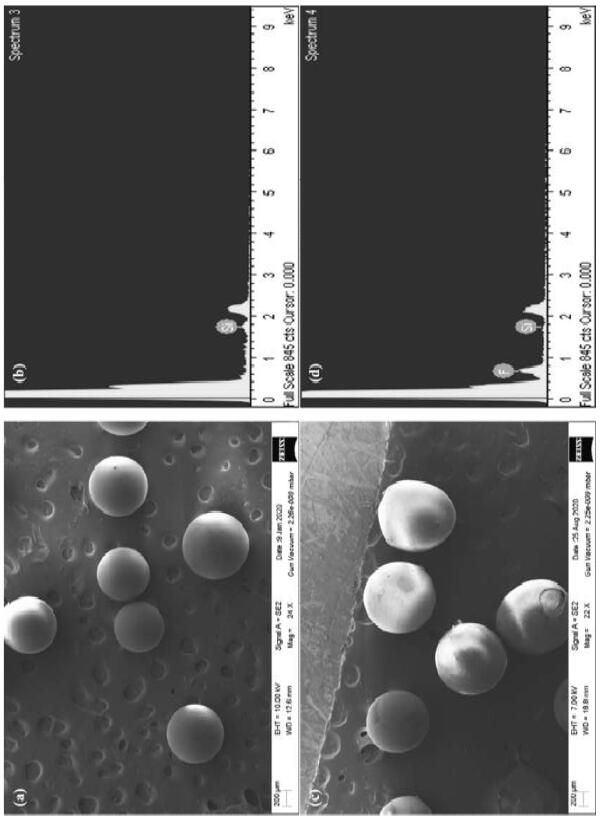

Embodiment 1

[0057] A preparation method of durable hydrophobic low-density high-strength polystyrene microspheres, the process is as follows

[0058] Step 1, dissolving 0.4 part of polyvinyl alcohol in 400 parts of deionized water to obtain an aqueous phase with a concentration of 0.1%.

[0059] Step 2, premix 20 parts of styrene, 5 parts of divinylbenzene, 5 parts of γ-methacryloyloxypropyltrimethoxysilane and 0.1 part of dibenzoyl peroxide to obtain an oil phase.

[0060] Step 3, the oil phase is slowly added to the water phase, and the stirring speed is controlled at 40 rpm and the temperature is 40° C. until the oil phase is completely added to the water phase.

[0061] Step 4, after all the oil phase is added to the water phase, the stirring speed is controlled to 60 rpm, and the temperature is gradually raised to 65° C. and then reacted for 1 hour.

[0062] Step 5: Suction filtration and washing to obtain spherical cores.

[0063] Step 6, add 10 parts of potassium type silica sol ...

Embodiment 2

[0067] A preparation method of durable hydrophobic low-density high-strength polystyrene microspheres, the process is as follows

[0068] Step 1: Dissolve 4 parts of cellulose ether in 400 parts of deionized water to obtain an aqueous phase with a concentration of 1%.

[0069] Step 2, premix 40 parts of styrene, 6 parts of divinylbenzene, 1 part of vinyltrimethoxysilane and 1.2 parts of azobisisobutyronitrile to obtain an oil phase.

[0070] Step 3, the oil phase is slowly added to the water phase, and the stirring speed is controlled at 100 rpm and the temperature is 60° C. until the oil phase is completely added to the water phase.

[0071] Step 4, after all the oil phase is added to the water phase, the stirring speed is controlled to 130 rpm, and the temperature is gradually raised to 100° C. and then reacted for 5 hours.

[0072] Step 5: Suction filtration and washing to obtain spherical cores.

[0073] Step 6, add 10 parts of potassium-type silica sol and 0.01 part of ...

Embodiment 3

[0077] A preparation method of durable hydrophobic low-density high-strength polystyrene microspheres, the process is as follows

[0078] Step 1, dissolving 3 parts of sodium dodecylbenzenesulfonate in 200 parts of deionized water to obtain an aqueous phase with a concentration of 1.5%.

[0079] In step 2, 26 parts of styrene, 5 parts of divinylbenzene, 3 parts of vinyltriethoxysilane and 0.25 parts of dibenzoyl peroxide are premixed to obtain an oil phase.

[0080] Step 3, the oil phase is slowly added to the water phase, and the stirring speed is controlled at 100 rpm and the temperature is 45° C. until the oil phase is completely added to the water phase.

[0081] Step 4: After the oil phase is all added to the water phase, the stirring speed is controlled to be 150 rpm, and the temperature is gradually raised to 70° C. and then reacted for 2.5 hours.

[0082] Step 5: Suction filtration and washing to obtain spherical cores.

[0083] Step 6, add 5 parts of potassium-type ...

PUM

| Property | Measurement | Unit |

|---|---|---|

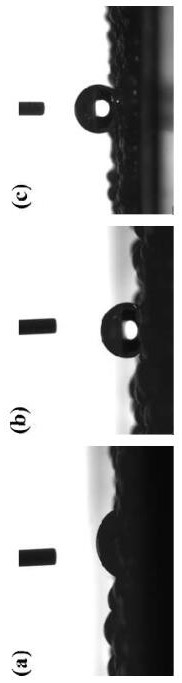

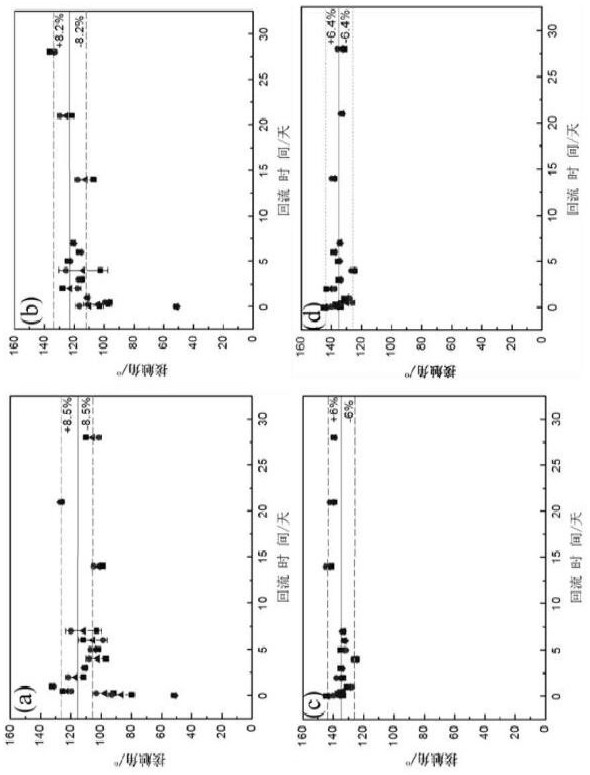

| contact angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com