Method for researching modification technology of high-activity single-variety shoe material powder

A technology for technical research and powder modification is applied in the field of modification and recycling of waste polymer materials, which can solve the problems of difficult recycling of shoe material waste, and achieve the effects of low cost, environmental requirements, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

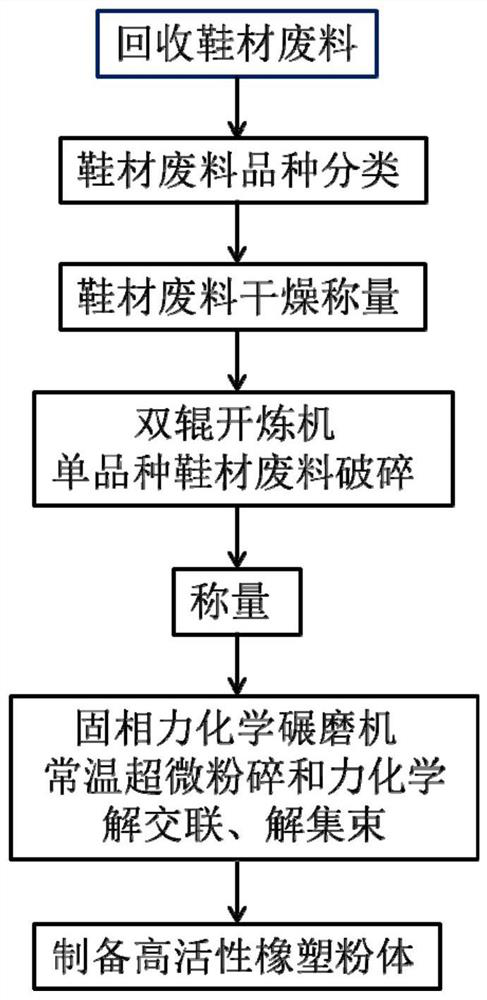

[0022] 1) Sorting and recycling of shoe material waste, using rubber shoe material waste (such as cutting scraps, waste products, defective products, etc.) as raw materials, and drying them.

[0023] 2) Weigh 5 kg of dry rubber shoe material waste and pretreat it with a double-roll mill to obtain crushed rubber waste.

[0024] 3) Weigh the crushed rubber shoe material waste obtained in step (2), and use mechanochemical milling activation technology to perform ultrafine pulverization and solid phase shear milling through a solid phase mechanochemical mill to finally prepare the particle size Highly active rubber powder with a size of 300 um;

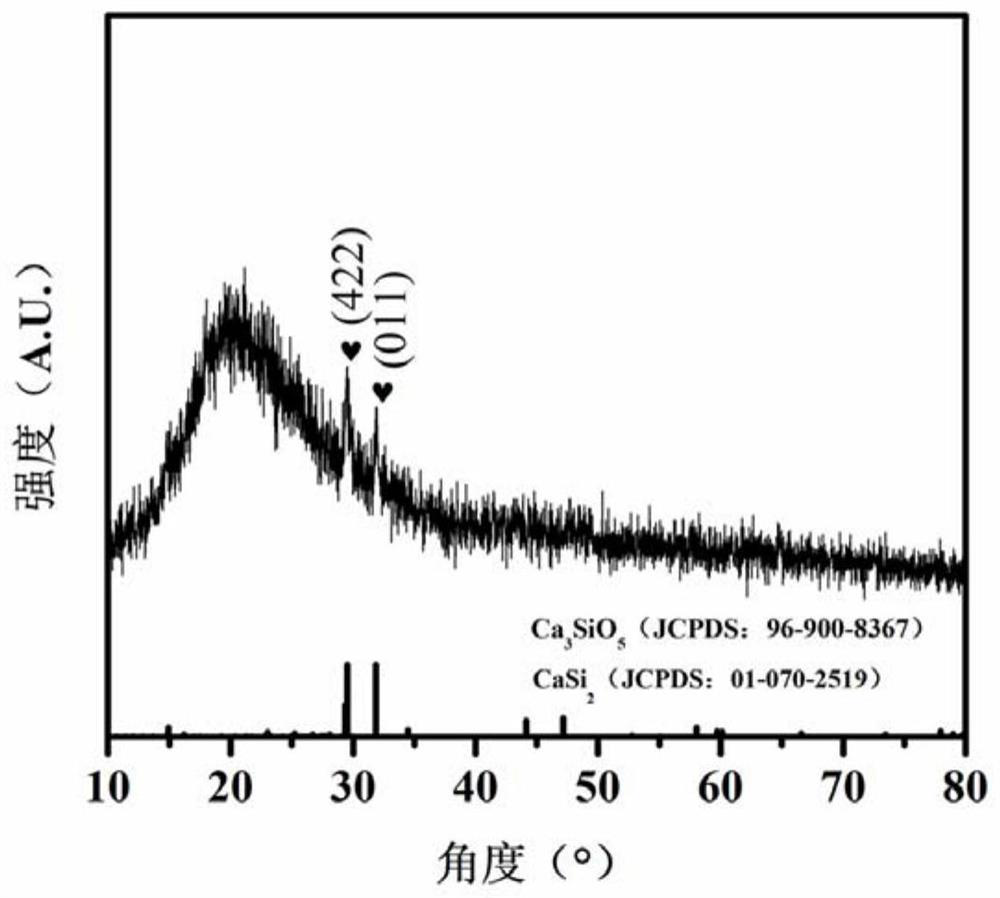

[0025] Obtained by XRD experiment figure 2 The X-ray diffraction pattern of the highly reactive rubber powder, by figure 2 It can be seen that the diffraction peak with a 2θ of 23.0° corresponds to the (002) crystal plane of carbon, and the diffraction peak with a 2θ of 29.5° corresponds to the Ca 3 SiO 5 The (422) crystal plane, an...

Embodiment 2

[0031] 1) Classify and recycle shoe material waste, use EVA shoe material waste (such as cutting scraps, waste products, defective products, etc.) as raw materials, and dry them.

[0032] 2) Weigh 10 kg of dry EVA shoe material waste, and pretreat it with a double-roll mill to obtain crushed EVA waste.

[0033] 3) Weigh the broken EVA shoe material waste obtained in step (2), and use mechanochemical milling and activation technology to perform ultrafine pulverization and solid phase shearing milling through a solid phase mechanochemical mill to finally prepare the particle size Highly active EVA powder with a size of 400 um;

Embodiment 3

[0035] 1) Classify and recycle the shoe material waste, use TPU shoe material waste (such as cutting scraps, waste products, defective products, etc.) as raw materials, and dry them.

[0036] 2) Weigh 8 kg of dry TPU shoe material waste and pretreat it with a double-roll mill to obtain crushed EVA waste.

[0037] 3) Weigh the broken TPU shoe material waste obtained in step (2), and use mechanochemical milling activation technology to perform ultrafine pulverization and solid phase shear milling on the solid phase mechanochemical mill to finally prepare the particle size Highly active TPU powder with a size of 200 um;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com