A kind of 3D printing photosensitive resin and its preparation method and application

A technology of photosensitive resin and 3D printing, which is applied in the field of 3D printing and photocuring, which can solve the problems of brittle photosensitive resin, uneven mechanical properties of parts in all directions, and poor interlayer adhesion, so as to improve the notched impact strength and improve mechanical properties. Performance and surface step effect, the effect of high interlayer adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0066] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

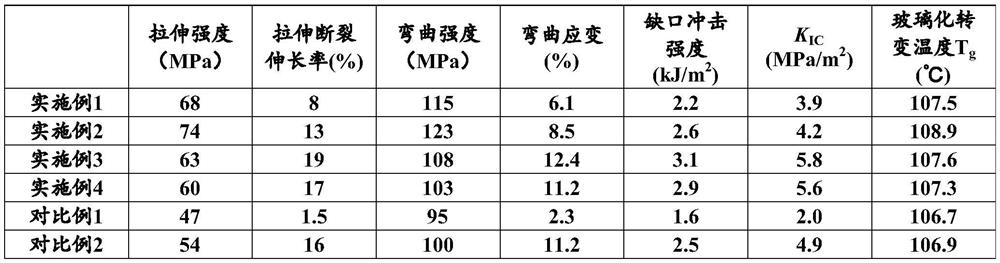

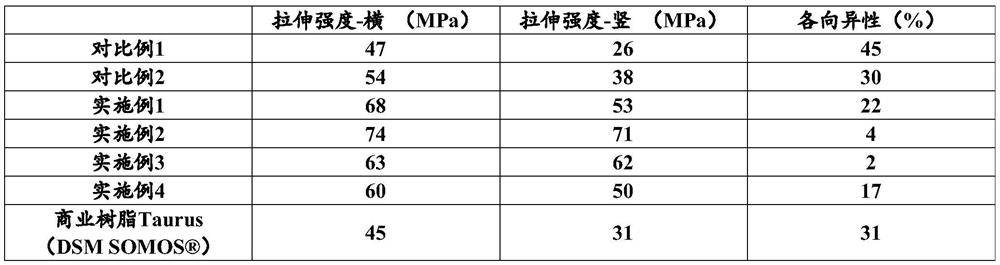

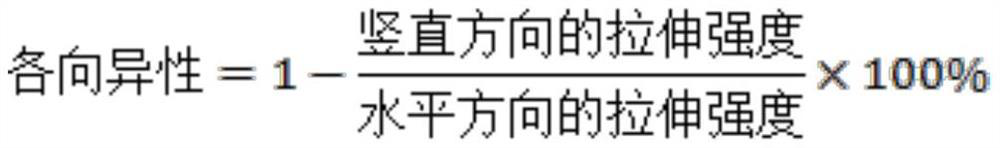

[0067] In the description of the present invention, it should be noted that the test process of tensile strength is completed with reference to ASTM D638. The test process of tensile elongation at break is completed with reference to ASTM D638. Th...

Embodiment 1

[0069] Preparation of modified styrene-butadiene rubber nanoparticles:

[0070] 100g styrene-butadiene latex (Jinan Shanhai Chemical Industry, solid content 34%, wherein butadiene content 75wt%, particle size 120nm), distilled water 150g, OP-10 0.5g, sodium dodecylbenzenesulfonate 0.3g, KPS 0.4g , stirred at 70°C for 30min, added dropwise 30.5g of methyl methacrylate and styrene mixture (molar ratio 1:1) at a rate of 10mL / h, and reacted at 80°C for 2 hours. Add 2 g of glycidyl methacrylate dropwise at a rate of 5 mL / h, react at 80°C for 1 hour, and protect under nitrogen throughout the above reaction. Add CaCl 2 The solution was demulsified, filtered and washed three times with hot distilled water, and then freeze-dried for 48 hours for later use.

[0071] 50 parts of prepolymer epoxy resin (DER331, Dow Chemical), 10 parts of prepolymer epoxy acrylate (CN104NS, Sartomer), 11 parts of reactive diluent ethoxylated trimethylolpropane triacrylate, Mix 20 parts of reactive dilue...

Embodiment 2

[0074] The preparation of modified styrene-butadiene rubber nanoparticles is the same as in Example 1.

[0075] 50 parts of prepolymer epoxy resin (DER331, Dow Chemical), 10 parts of prepolymer epoxy acrylate (CN104NS, Sartomer), 11 parts of reactive diluent ethoxylated trimethylolpropane triacrylate, Mix 18 parts of reactive diluent 3-ethyl-3 hydroxymethyl oxetane, heat to 80°C and stir until transparent state; add 5 parts of modified styrene-butadiene rubber nanoparticles prepared above, Stir for 6h (speed 2500r / min); add 2 parts of photoinitiator 1-hydroxycyclohexyl phenyl ketone, 4 parts of photoinitiator diphenyl-(4-phenylthio)phenylsulfonium hexafluoroantimonate, Heat to 60° C. with a constant temperature magnetic stirring device, and stir for 1 h in the dark to prepare a resin for use.

[0076] Use a 355nm laser stereolithography (SLA) 3D printer for 3D printing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com