Flexible and elastic skeleton supporting type non-woven fabric and preparation method thereof

An elastic skeleton and non-woven fabric technology, applied in textiles and papermaking, etc., can solve the problems of poor elasticity and low wrinkle resistance of non-woven fabrics, and achieve strong wrinkle resistance, improved wrinkle resistance, and good fire and flame retardant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

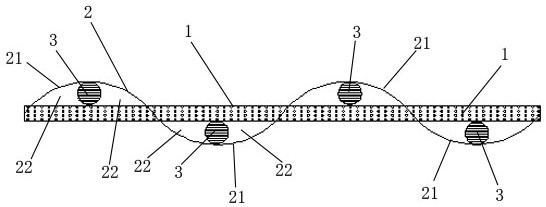

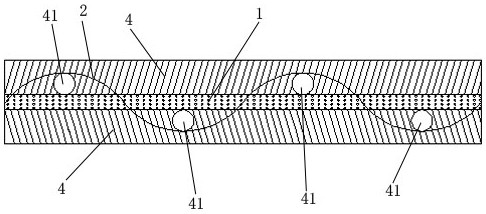

[0027] Such as figure 1 and 2 As shown, a kind of flexible and elastic skeleton support type non-woven fabric, comprises non-woven fabric inner core layer 1, twisted fiber filament 2, surface coating 4; Both sides of described non-woven fabric inner core layer 1 are provided with The surface coating 4; the non-woven fabric inner core layer 1 and the surface coating 4 on both sides are connected in waves through a plurality of twisted fiber filaments 2; the components and weights included in the surface coating 4 The parts are as follows: 100 parts of acrylic resin, 5 parts of silica gel, 10 parts of glass fiber powder, 5 parts of molybdenum disulfide, 5 parts of nylon fiber powder, and 5 parts of ammonium dihydrogen phosphate; A plurality of hollow air-permeable and moisture-discharging pores 41 are uniformly arranged between the sides; the twisted fiber filaments are twisted fibers of flax fiber and polyether ester elastic fiber. Further, the thickness of the non-woven inne...

Embodiment 2

[0035] Such as figure 1 and 2 As shown, a kind of flexible and elastic skeleton support type non-woven fabric, comprises non-woven fabric inner core layer 1, twisted fiber filament 2, surface coating 4; Both sides of described non-woven fabric inner core layer 1 are provided with The surface coating 4; the non-woven fabric inner core layer 1 and the surface coating 4 on both sides are connected in waves through a plurality of twisted fiber filaments 2; the components and weights included in the surface coating 4 The parts are as follows: 100 parts of acrylic resin, 7 parts of silica gel, 13 parts of glass fiber powder, 8 parts of molybdenum disulfide, 7 parts of nylon fiber powder, and 6 parts of ammonium dihydrogen phosphate; A plurality of hollow air-permeable and moisture-discharging pores 41 are evenly arranged between the two sides of the layer 1; the twisted fiber filaments are twisted fibers of flax fiber and polyetherester elastic fiber. Further, the thickness of the...

Embodiment 3

[0043] Such as figure 1 with 2 As shown, a kind of flexible and elastic skeleton support type non-woven fabric, comprises non-woven fabric inner core layer 1, twisted fiber filament 2, surface coating 4; Both sides of described non-woven fabric inner core layer 1 are provided with The surface coating 4; the non-woven fabric inner core layer 1 and the surface coating 4 on both sides are connected in waves through a plurality of twisted fiber filaments 2; the components and weights included in the surface coating 4 The parts are as follows: 100 parts of acrylic resin, 10 parts of silica gel, 15 parts of glass fiber powder, 10 parts of molybdenum disulfide, 10 parts of nylon fiber powder, 7 parts of ammonium dihydrogen phosphate; A plurality of hollow air-permeable and moisture-discharging pores 41 are evenly arranged between the two sides of the layer 1; the twisted fiber filaments are twisted fibers of flax fiber and polyetherester elastic fiber. Further, the thickness of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com