Preparation method of non-toxic nanoscale plastic microparticles

A nano-scale, non-toxic technology, applied in the field of environmental materials, can solve problems such as interference with toxicology experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

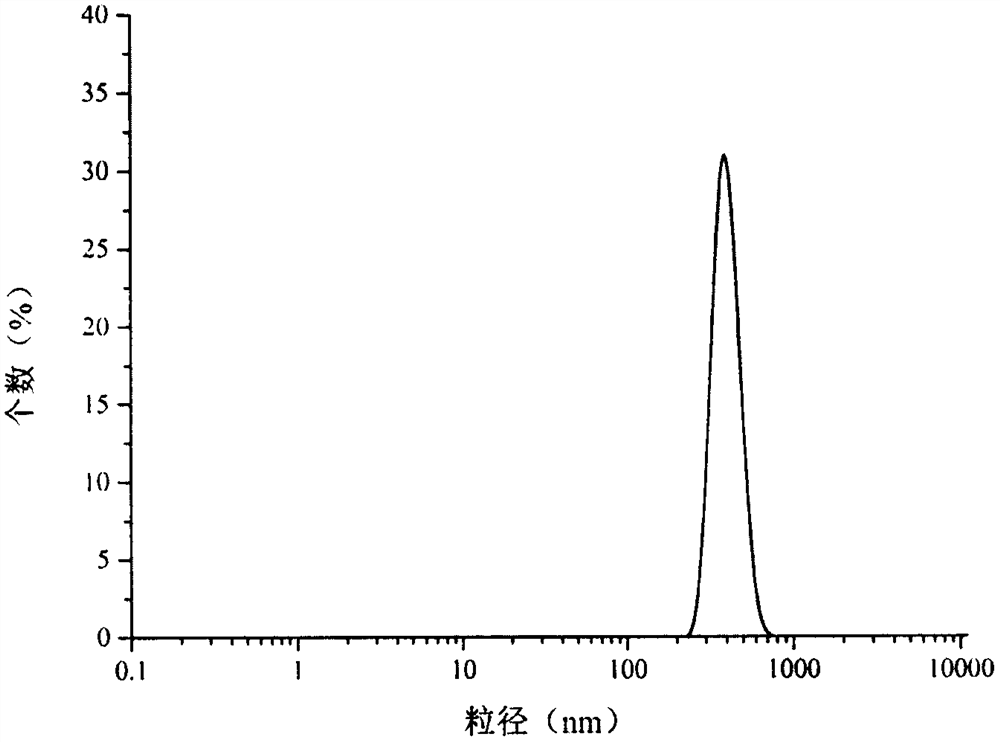

[0022] Weigh 1g of PET powder and place it in a 100mL round bottom flask, add 10mL of 90% sulfuric acid aqueous solution, stir until completely dissolved, add 10mL of 20% sulfuric acid solution while stirring, continue stirring for 2h after cooling to room temperature, and transfer the suspension into a 50mL centrifuge tube, centrifuge at 2800g for 1h, transfer the upper layer of PET plastic to another centrifuge tube, and centrifuge and wash 5 times. At this time, the pH of the solution is measured to be 7. Dissolve lipid in 100mL pure water, add 25mL rhamnolipid solution to the centrifuge tube containing the precipitate, sonicate for 20min, vibrate at 180r / min for 20min, let stand for 48h, take the upper layer suspension and sonicate for 1h, take 1.5mL to use nanometer particle size Analyze its particle size with zeta potential molecular weight analyzer, the result is as follows figure 1 As shown, the measured particle size distribution is 295-615nm.

example 2

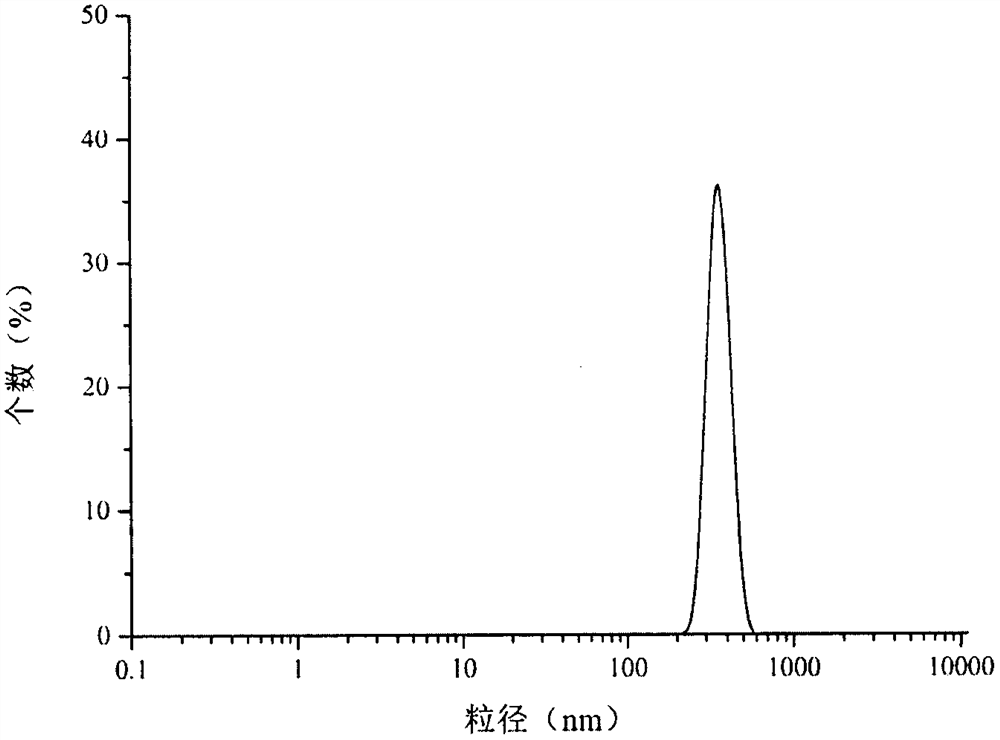

[0024] Weigh 1g of PET powder and place it in a 100mL round bottom flask, add 10mL of 90% sulfuric acid aqueous solution by volume, stir until completely dissolved, then add 10mL of 10% sulfuric acid solution while stirring, continue to stir for 2h after cooling to room temperature, and transfer the suspension into a 50mL centrifuge tube, centrifuge at 2800g for 1h, transfer the upper layer of PET plastic to another centrifuge tube, and centrifuge for 4 times. At this time, the pH of the solution is measured to be 7. Transfer the precipitate to a 50mL centrifuge tube. Dissolve lipid in 100mL pure water, add 25mL rhamnolipid solution to the centrifuge tube containing the precipitate, sonicate for 20min, vibrate at 180r / min for 20min, let stand for 48h, take the upper layer suspension and sonicate for 1h, take 1.5mL to use nanometer particle size Analyze its particle size with zeta potential molecular weight analyzer, the result is as follows figure 2 As shown, the measured par...

example 3

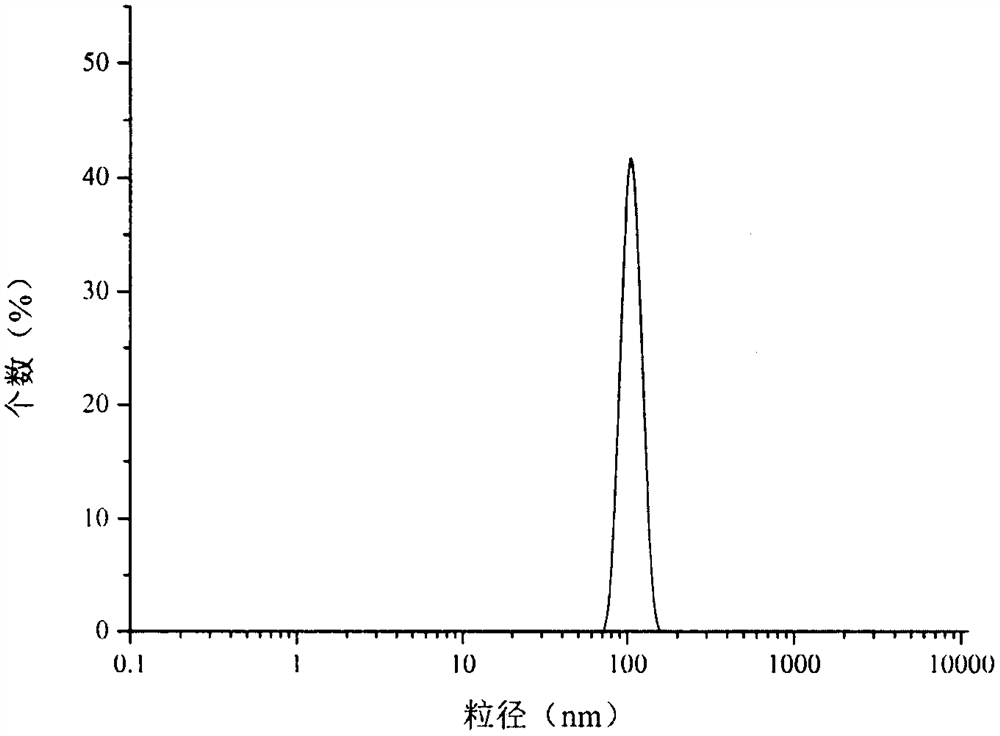

[0026] Weigh 1g of PET powder into a 100mL round bottom flask, add 10mL of sulfuric acid aqueous solution with a volume fraction of 85%, stir until completely dissolved, add 10mL of 10% sulfuric acid solution while stirring, continue stirring for 2h after cooling to room temperature, and transfer the suspension into a 50mL centrifuge tube, centrifuge at 2800g for 1h, transfer the upper layer of PET plastic to another centrifuge tube, and centrifuge and wash 5 times. At this time, the pH of the solution is measured to be 7. Dissolve lipid in 100mL pure water, add 25mL rhamnolipid solution to the centrifuge tube containing the precipitate, sonicate for 20min, vibrate at 180r / min for 20min, let stand for 48h, take the upper layer suspension and sonicate for 1h, take 1.5mL to use nanometer particle size Analyze its particle size with zeta potential molecular weight analyzer, the result is as follows image 3 As shown, the measured particle size distribution is 91-142nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com